Bruschi Company News

In today's context, where sustainability is a priority, Bruschi has decided to adopt responsible energy solutions for 2024 and 2025, aimed at building a more sustainable future.

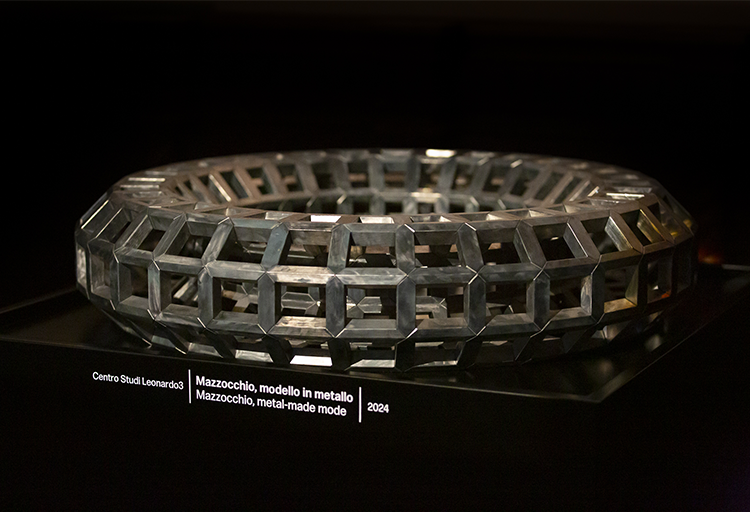

Bruschi, commissioned by the Leonardo3 Museum - The World of Leonardo in Milan, has brought to life an extraordinary work inspired by Leonardo da Vinci’s famous drawing: the Mazzocchio. This intricate structure, made up of 32 octagonal sections and 512 individual pieces, was unveiled to the public on November 14, 2024, during an exclusive preview at the milanese museum.

We are pleased to announce that, effective December 1st, 2024, Bruschi will finalize its merger with Sapre, marking an important milestone in its growth strategy.

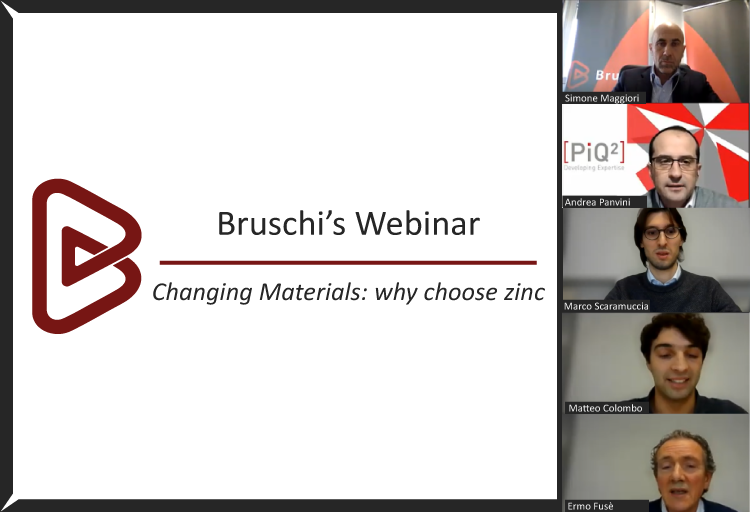

A heartfelt thank you to everyone who joined our webinar, “Comparing Materials in Die Casting: Advantages and Applications of Zamak and Aluminum.” It was inspiring to share insights on the properties and applications of zamak and aluminum, exploring the strengths of each material in the die casting field.

In recent years, the growing awareness of climate change and the demand for sustainable business practices have driven many industries to reconsider their energy strategies. In this context, Bruschi has embarked on an ambitious collaboration with Siemens AG, focusing on the integration of renewable energy sources into their daily operations.

We are pleased to invite you to participate in a webinar that will provide an in-depth comparison of materials in the die casting industry, with a particular focus on zinc and aluminum. The event, titled "Materials compared in die casting: advantages and applications of zamak and aluminum", will be streamed live on Zoom on Thursday, November 7, 2024, at 11:00 AM (CET).

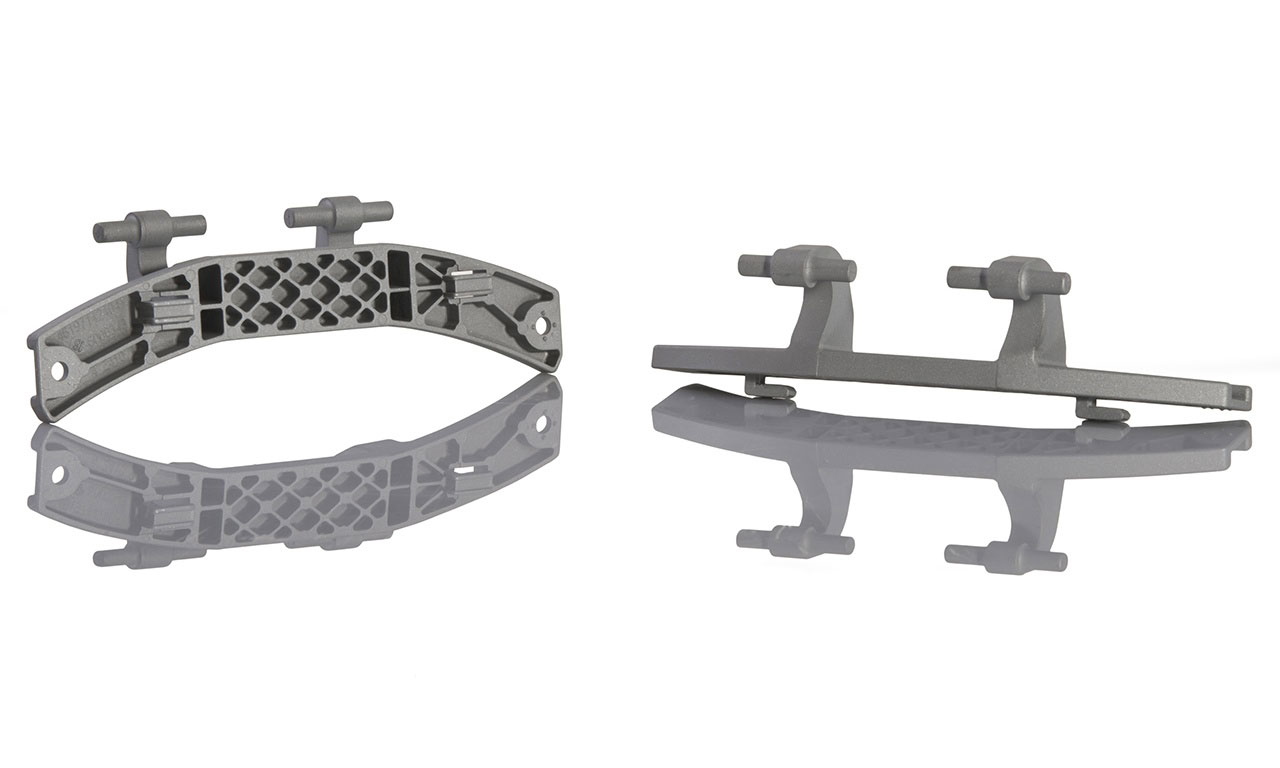

In 2023, Bruschi successfully completed an important innovation challenge in the development of zinc die-cast products, requested by a German company in the automotive sector, the mass production of a component of very small dimensions that respected the stringent weight constraint imposed by the customer.

We are pleased to announce that Bruschi has successfully obtained the TISAX® ( Trusted Information Security Assessment) certification eXchange - (ISO/IEC 27001), further consolidating its commitment to the data security of suppliers, collaborators, and security systems.

September 20, 2023-In the setting of the Die Casting Congress & Tabletop event in Grand Rapids, MI, Bruschi won the fifth NADCA Award in her history.

The Bruschi75 event took place on Saturday, 16 September 2023, at our factory in via Mendosio 26 in Abbiategrasso (MI): the birthday for the first 75 years of Bruschi.

Bruschi S.p.A. finalized the acquisition of 100% of Sapre S.r.l., a company specialized in the non-ferrous alloys sector, active in the market since 1988, with the aim of entering the aluminum alloy die-casting market.

On Monday, May 29th, 2023, the "Past, present, future" event organized by Bruschi for all its employees was held in Cascina Caremma in Besate. The event lasted the entire day and stood out as a Team Building moment dedicated to all Bruschi collaborators in the name of corporate values: Trust, Appreciation, and Accountability.

Bruschi recently won another prestigious award for its exceptional ability to overcome the current limits of zinc alloy die-casting technology.

The prize was awarded during the second annual Zinc Die Casting Conference in Chicago from June 5-7, 2023.

On 4 May 2023, the appointment "1h of... with..." organized by Bruschi for all his collaborators and customers, friends, and selected suppliers was back on stage: the host of this meeting was the coach of the Italian men's national team of volleyball, World and European Champion Ferdinando De Giorgi, known as Fefè.

For the second year running, Bruschi has been chosen among the 2023 Export Champions. This recognition, curated even for this second year by Statista on behalf of Il Sole 24 Ore, honours Bruschi for its export achievements in 2021.

On December 2, 2022 Bruschi held its year-end event at the Cagnoni Theater in Vigevano. It was an opportunity for the company’s partners, Paolo Rastelli and Simone Maggiori, to present to all employees the 2022 results and summarize the main challenges facing the company in 2023.

In October 2022, Ecovadis released its Assessment: a service that allows you to assess your company’s sustainability impact based on concrete data defined by the platform.

Bruschi scored over 47/100 and, for this achievement, was awarded an Ecovadis Bronze Medal and an Ecovadis Sustainability Certificate. Thanks to these results, Bruschi is among the 50 per cent of companies evaluated by EcoVadis with the highest scores.

On Monday, May 16, 2022, a new appointment was held as part of the “1 hour of… with…” initiative, the webinar series organized by Bruschi for all its employees and selected stakeholders.

On Tuesday, March 1st, 2022, a new appointment as part of the initiative "1 hour of ... with ..." had the Mayor of Milan Giuseppe Sala as a guest. "1 hour of ... with ..." is the webinar cycle organized by Bruschi for all its employees and selected stakeholders, which aims to provide general food for thought on the present: moving from the most current to the vision of the future.

New appointment with the webinar cycle "1 hour of ... with ...": guest of the day prof. Marco Fortis

On Monday, February 7th, 2022, a new appointment was held as part of the "1 hour of ... with ..." initiative, the webinar cycle organized by Bruschi for all employees and recently extended to stakeholders and former employees, which aims to provide food for thought on socio-economic issues.

The statistical tools and technologies seminar will be held on February 4th, 2022, at 2.00 pm.

Bruschi's project will be presented, curated by the Senior Process Engineer of the Roberto Rodolfo Gaggianesi group, with an introduction to the problem and molding technologies.

On Friday, January 21, 2022, a new appointment was held as part of the "1 hour of ... with ..." initiative, the webinar cycle organized by Bruschi for all employees and recently extended to stakeholders and former employees, which aims to provide food for thought on socio-economic issues or related to the concept of "doing business."

The pandemic year between 2020 and 2021, with the economic paralysis resulting from prolonged lockdowns, was a period of stress and has put many realities to the test, still it has also allowed some companies to prove their value.

A new appointment was held on Monday, November 29, 2021, as part of the "1 hour of ... with ..." initiative, the webinar cycle organized by Bruschi and open to all employees, which aims to provide food for thought on socio-economic issues or linked to the concept of "doing business".

On 10 November 2021, Bruschi obtained an important recognition from Schneider Electric in terms of sustainability. This recognition was conferred after a Vigilance Audit carried out in Bruschi, which touched the aspects of the company's economic development, ethics, work, and obviously the environmental and safety ones.

Bruschi’s innovative approach and continuous pursuit of excellence have enabled the company to achieve another important milestone: Bruschi’s success at the International Die Casting Competition 2021 in the ZINC – over 6 oz category.

Bruschi’s relentless research will allow the company to be a protagonist at the Minitab Insights 2022 Global Conference, which will be held on April 4 to 6 in Scottsdale, Arizona.

Bruschi, always careful about looking for solutions that can bring value to its customers, has set up a new technological innovation department called AESI: Automation Engineering & System Integration.

On Tuesday 15 June 2021, the first speech organized by Bruschi was held as part of the new initiative "1 hour of... with...", a cycle of webinars open to all employees in which are involved authoritative speakers, in turn, able to provide ideas and insight on the current socio-economic situation and on the issues of “doing business” today, with valuable contributions born from one's own experience and able to favor the collective and individual reflection of the webinar participants.

Bruschi are pleased to announce that our colleague Engr. Marco Galbiati – mechanical designer at Bruschi Spa – was awarded with the 2020 Aldo Daccò Prize on January 18th, 2021.

The first Bruschi webinar – entitled “Zinc Die-Casting: A Look into the Future” – will be held via Zoom on February 23rd, 2021 at 3pm (CET-GMT+1). The Webinar will be an opportunity to discover the world of zinc die casting, the peculiarities of the raw material, its several sectors of application, the new processes and the technologies of the future.

Bruschi has always dedicated great attention to training activities by reserving its employees refresher courses for the development of skills and competences. Also in this first part of 2020, the company has continued its mission with a training course aimed at developing managerial skills among employees.

Also in 2020 Bruschi has been selected as “Champions” company qualifying itself among the 1000 best Italian SMEs with a turnover between 20 and 150 millions of Euros.

Bruschi, after the reopening of its plants in Italy on May 4th, restarts its activities in the US plant.

Bruschi, after the partial resumption of April 6th of the activities related to strategic supply chains, from Monday 4th of May resumes its activities in Italy at full capacity.

Given the measures that all countries are gradually implementing and the rapid global spread of COVID-19, Bruschi stops production activities in its Italian plants and in its plant in the United States. The closure of the plants is aimed at aligning the company with the measures adopted in the countries where Bruschi is present, in order to facilitate the solving of the emergency and to guarantee all its employees the greatest possible safety.

Below an interview with Eng. Paolo Rastelli, CEO of Bruschi, about recruiting and talent attraction initiatives of the company.

On Monday 20th of January the financial transaction of the acquisition of HUF North America Die Cast by Bruschi has been concluded.

On December 9th 2019 Bruschi in agreement with HUF finalized the acquisition of HUF production unit in Milwaukee.

On Monday 2nd December 2019 Paolo Rastelli and Simone Maggiori, CEO and Head of Sales of Bruschi S.p.A., have been invited by Professor Alessandro Bruni of Pisa University to speak about sales strategy and digital marketing to the students of the Master Degree in Management Engineering.

We proudly announce that Open Factory initiative in Bruschi ended yesterday with a great audience success.

On the 24th November 2019 Bruschi is taking part in Open Factory initiative and it is opening its gates to the public.

Last week Bruschi has been awarded as 2019 Excellent Company at the XI edition of Global Strategy Osservatorio PMI, an observatory of Italian SMEs. This is the second time that Bruschi gets this award, thus confirming its position on the market and its growth over the last few years.

Save the date: on the 24th of November 2019 Bruschi is going to open its gates to the public.

We made some new videos that show our productive process and the characteristics of some components.

Industrial zinc life cycle is based on the principles of circular economy and it contributes in different ways to the protection of our Earth. In this post we are going to describe how zinc, thanks to its countless properties, positively impacts on our planet.

Bruschi has been selected among the 600 best Italian SMEs for the project “Champions 2019” by ItalyPost and on the 15th of March it will be attending the event organized by L’Economia, the economic voice of Corriere della Sera, at the head office of the Italian Stock Exchange.

White goods manufacturers are facing new challenges due to customers’ growing awareness on sustainability and recycling: taking into account these needs and defining the right practices can lead to sales improvement.

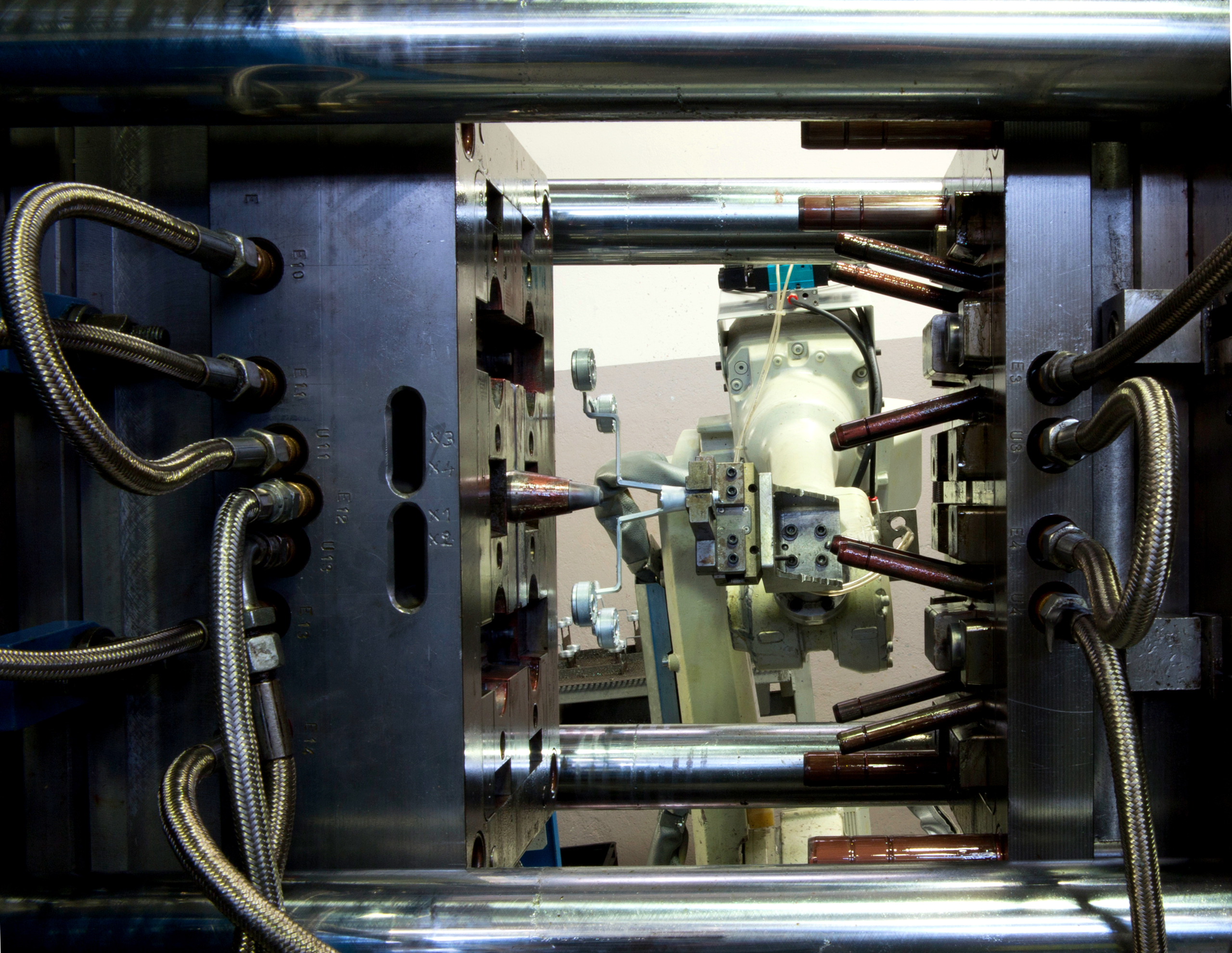

This year Bruschi has purchased new die casting machines to improve its industrial machinery in its foundry. Bruschi has always been aware of the importance of innovation and technology, the business philosophy is indeed based on three mainstays: mass-production, co-design and technology.

As every year, on November the 22nd Bruschi will attend the PMI Day at Politecnico di Milano: a scientific-technological university which trains engineers and industrial designers that have the required knowledge to start their career in Bruschi.

Seventy years after its birth Bruschi goes on its excellence path with the aim to serve its customers and to offer to the market innovative and technologically highly-developed solutions.

Every year, agencies publish new reports regarding development and growth of zinc die casting in automotive. According to a study by Envision Inteligence, in 2018 the value of zinc die casting market will be of $2.55 billion dollars, and it is expected to grow up to $2.92 billion by 2024.

After some recent internal changes, such as the decision to expand oversea, Bruschi managers decided to internationalize the official company website: starting Wednesday 11th April, Bruschispa.it becomes Bruschitech.com

Bruschi representatives are going to attend IZA 2018 Zinc Die Casting Conference - North America, held in Sheraton Chicago O’Hare Airport Hotel from the 4th to the 6th of June.

After more than 70 years working with zinc die casting technologies and dealing with both Italian and European customers, Bruschi has decided to undertake a new challenge: the opening of a new plant in the US.

Between the 16th and 18th of January it was held in Nuremberg the 11th edition of EUROGUSS, the largest European trade fair dedicated to the world of die casting. Bruschi was attending the exhibition with a stand in Hall 6.

Here in Bruschi we are well-aware that continuous employees training and learning are the keys to stay competitive in a world that is quickly evolving.

Zinc proves to be a reliable ally for a circular economy model, since not only does it maximize the lifespan of the product without altering their recyclability, but it’s in itself an highly recyclable material. This is highly compatible with circular economy goals, which aims to reduce new resource exploitation through use of recycling.

Many parts of white goods are made in zinc die casting thanks to metal's features. In general, the specific weight of molten metal (6,7 gr/cm³) could be an issue about limited weight requirements of a major appliance. Bruschi has the solution for this issue.

The differential advantage could be the best way to improve the selling rate in small appliances world, in particular for coffee machine industry.

To define Industry 4.0, in particular Foundry 4.0, it is really important to understand the new point of view, not just listing tools. Big Data, Open Data, IOT, Machine-to-Machine, Cloud Computing, Human-Machine Interaction and Add-on Additive Manufacturing are necessary: but are just devices or machines without a new business philosophy.

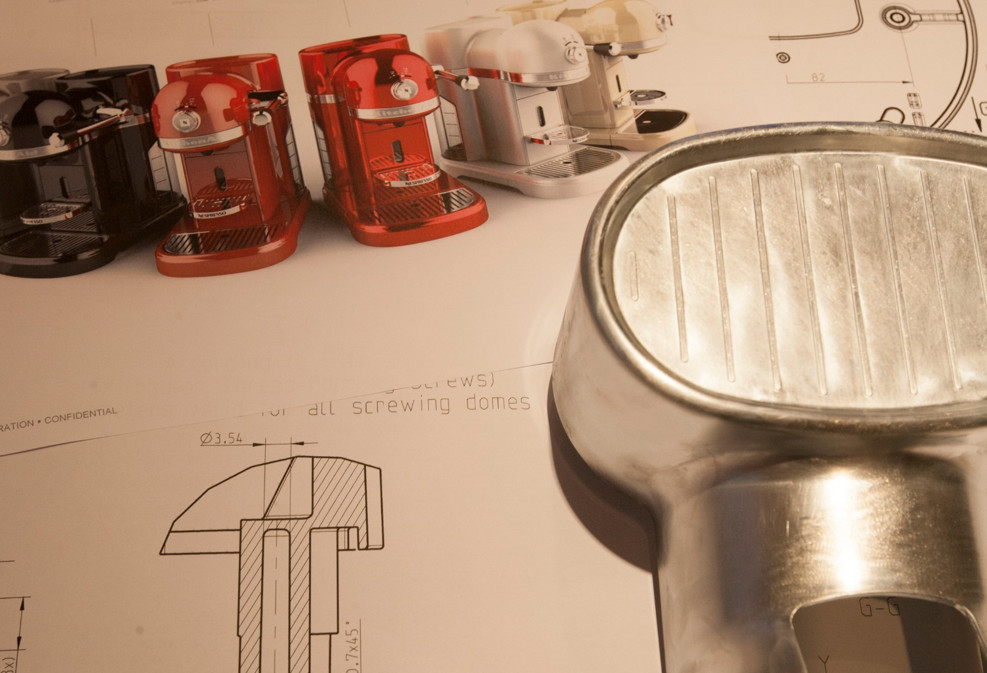

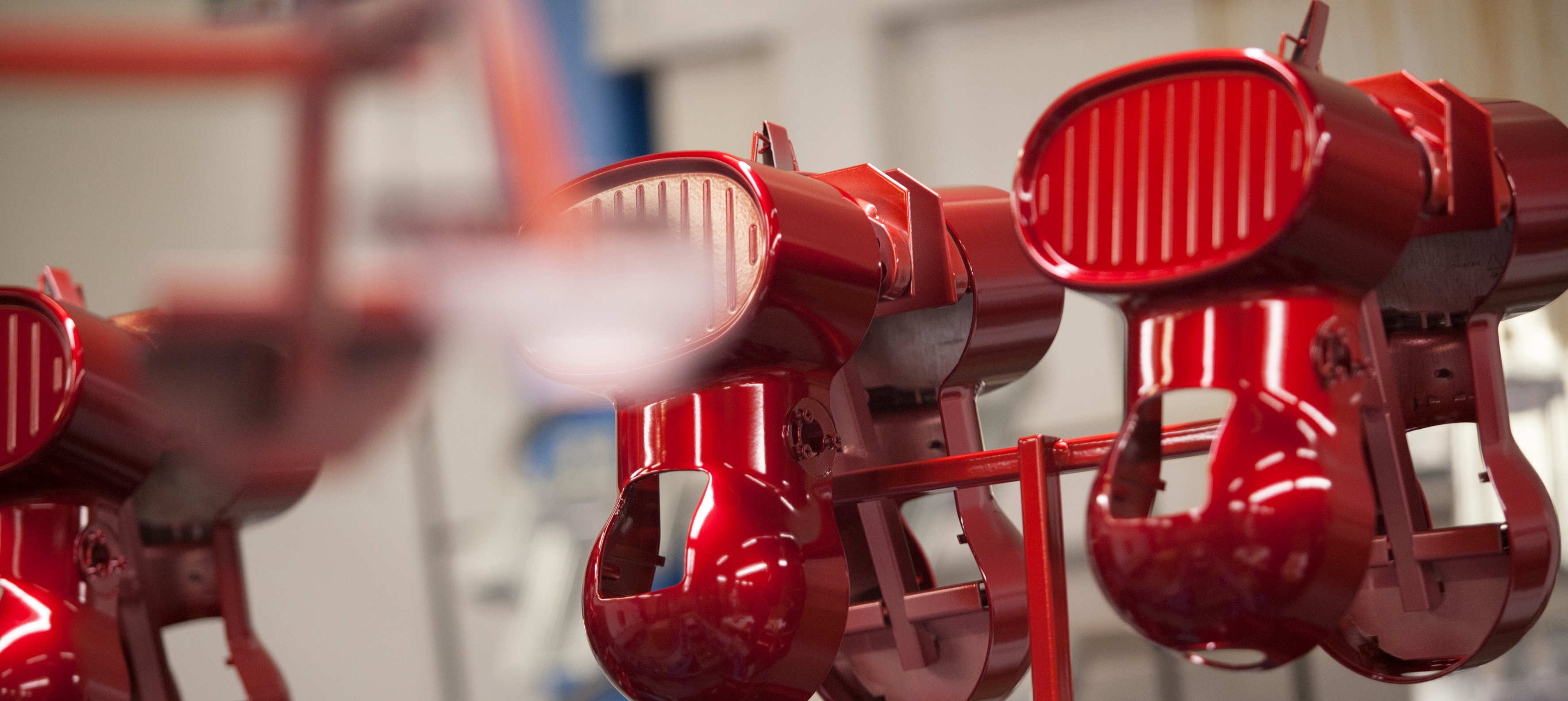

On September the 23rd Bruschi in collaboration with the American home appliances brand KitchenAid won the prestigious European Zinc Die Casting Competition 2016 for the product Nespresso KitchenAid Artisan 5KES0503.

Last Saturday at Villa Necchi alla Portalupa in Gambolò the Company organized a big party to thank Mr. Marco Bruschi for his work for having led Bruschi for a long time.

Nowadays kitchen appliances industry is in continuous improvement. Connected devices, thanks to digitalization, are all around us and coffee makers are riding the wave as ground-breaking products.

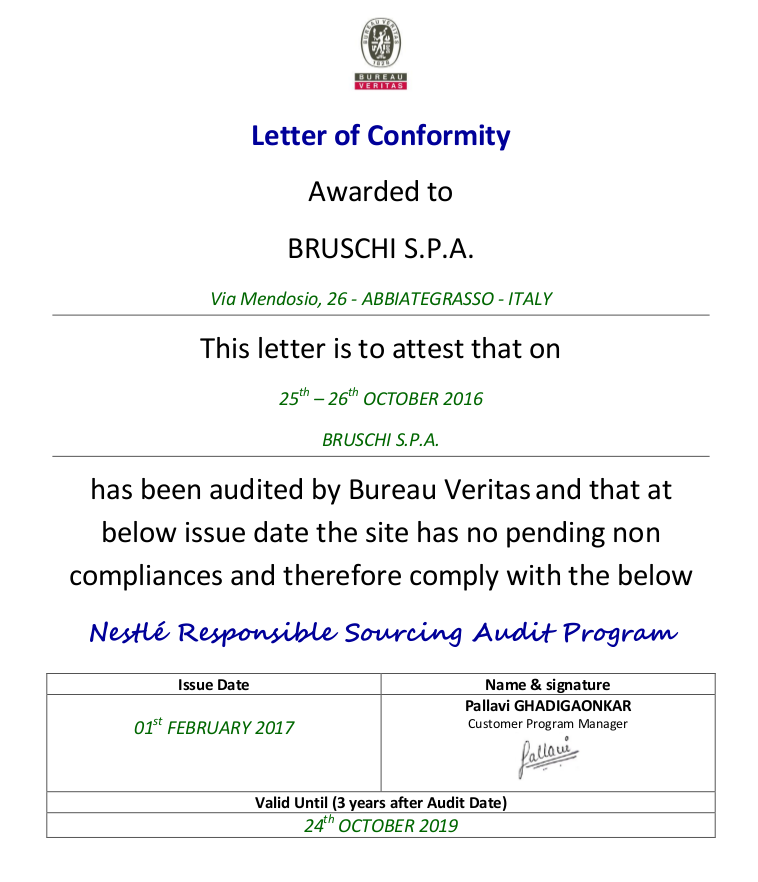

Bruschi achieved the important certification SMETA 4-Pillars. This certification has been organized by Sedex, no-profit membership organization dedicated to drive improvements in responsible and ethical business practices in global supply chains. To obtain this certificate Bruschi has been audited by Bureau Veritas, global leader in testing, inspection and certification designed by Sedex.

Zinc is a chemical element that is the 27th most abundant element in the Earth’s crust. Naturally occurs in air, water, soil and biosphere, in fact it is contained in many rocks and minerals, in plants and animals. Zinc is essential to all lives.

Bruschi, expert in zinc die casting field and supplier for many important automotive manufacturers, suggests to use zinc instead of other materials to obtain a better product: from its aesthetic side to its functional one.

Bruschi, as a die casting supplier of some of the most important manufacturers in this field, suggests to use zinc to develop components for sunroofs to take advantages of design, materials, processes and systems.

An innovative company is characterized by optimized tools and use of advanced process developed with its suppliers and its internal resources. To keep a company always competitive on the market and to offer always better solutions to its clients Bruschi developed an internal structure of Continual Improving. This structure is handled by a dedicated team, which has the aim of studying and increasing the efficiency of industrial processes.

This article reports an interview with Paolo Rastelli, Bruschi CEO, that explains is point of view and its experience about Industry 4.0 and Stain.

An intense and important year for the company is closing. The company has been a leading character in 2016: the change of ownership, acquisitions, new services offered to clients, consolidation of turnover and victory of awards.

People’s progression or company competitiveness are strictly linked to their ability to promote and start innovation processes, this is a capacity that is possible to reach only through updated educational path and professional qualifications: a constant improving that allows to be updated with better skills.

Last Friday in Vigevano Bruschi met a selection of its suppliers to present the new company asset, its business results and future scenarios.

On November the 10th, the company has participated at PMI DAY 2016 at the University Politecnico di Milano, in Bovisa area (Milan).

It have been a meaningful period for Bruschi, thanks to the prestigious awards won and the amazing editorials published on important Italian newspaper.

On October the 18th Bruschi's technicians were in Parma for CAE CONFERENCE 2016, the ideal event and venue to discuss the increasing relevance of "Simulation Based Engineering and Sciences" as a part of the synergistic environment in engineering simulation.

On November the 10th, the company will be at the University Politecnico di Milano, in Bovisa area (Milan), for PMI DAY 2016. It will be an important recruiting event: a career day for students and graduates of PoliMi.

Bruschi wins the prestigious NADCA award during the 2016 International Die Casting Competition. This award represents another important recognition of Bruschi’s innovative approach and strive for excellence. Another win for Bruschi after the prestigious European Zinc Die Casting award.

Bruschi has been acquired by MESHPA SRL

Bruschi Spa guarentees its future successful growth path thanks to a friendly management buyout. The company has already started to work on implementing small organizational improvements that will enable Bruschi Spa to better address present and future challenges.

Brescia, Italy (23rd September 2016) — Industrial design and mass production Italian company Bruschi and American home appliance brand KitchenAid have won the prestigious European Zinc Die Casting Competition 2016 for Nespresso KitchenAid Artisan 5KES0503.