- Home

- Sectors

Zinc die casting sectors

The range of Bruschi’s solutions: creativity and reliability that have their roots in Made in Italy.

The versatility of zinc alloys and the hot chamber die-casting technology allow to obtain components for various industries of application and able to respond to different kinds of requirements: aesthetic, technical or functional. The components produced in Bruschi are part of everyday life, we turn to global markets by offering targeted and adaptable solutions to each production sector.

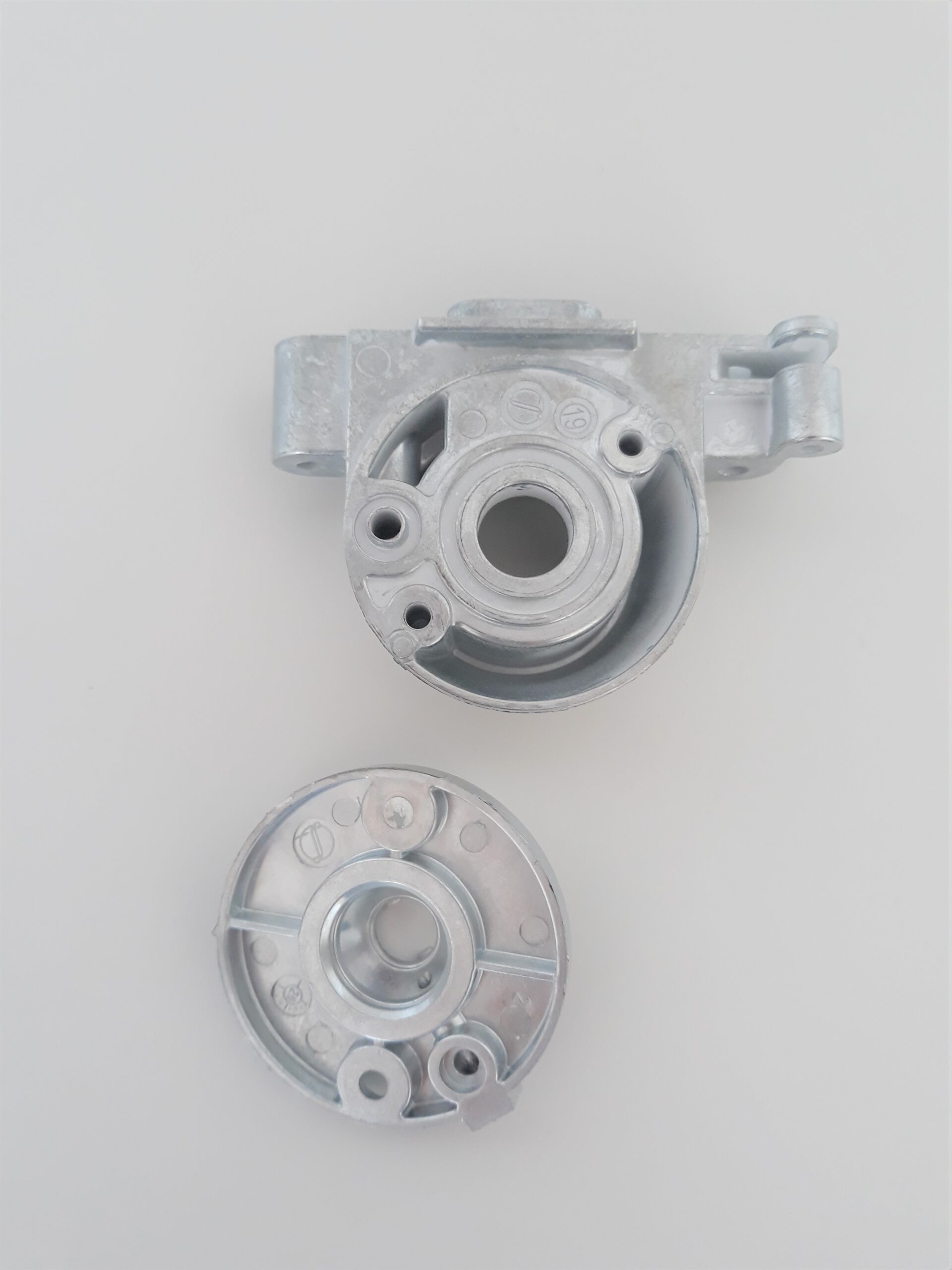

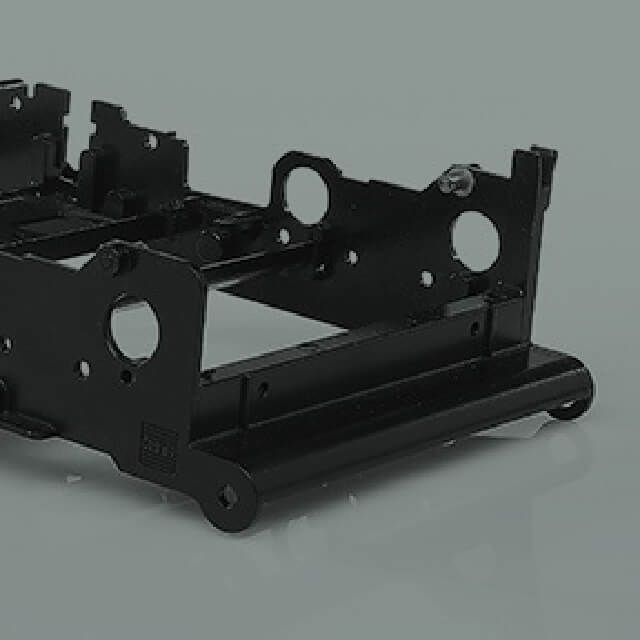

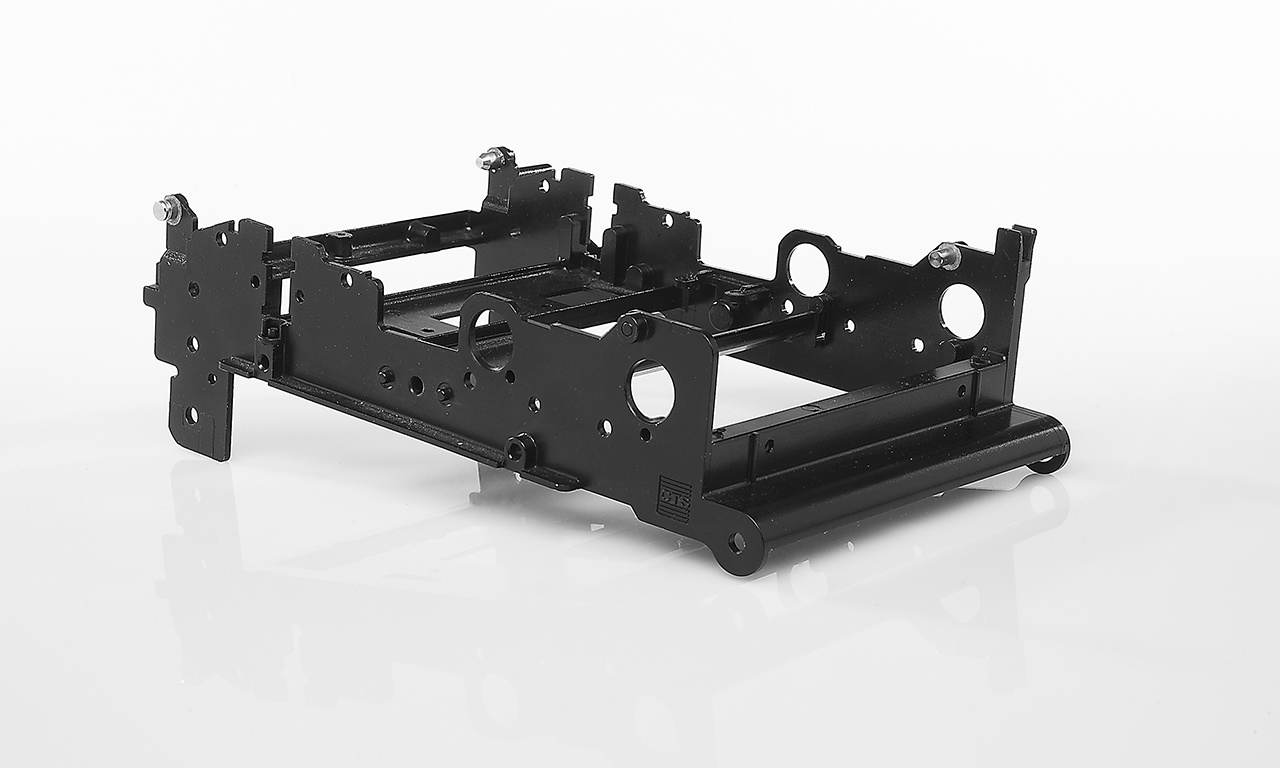

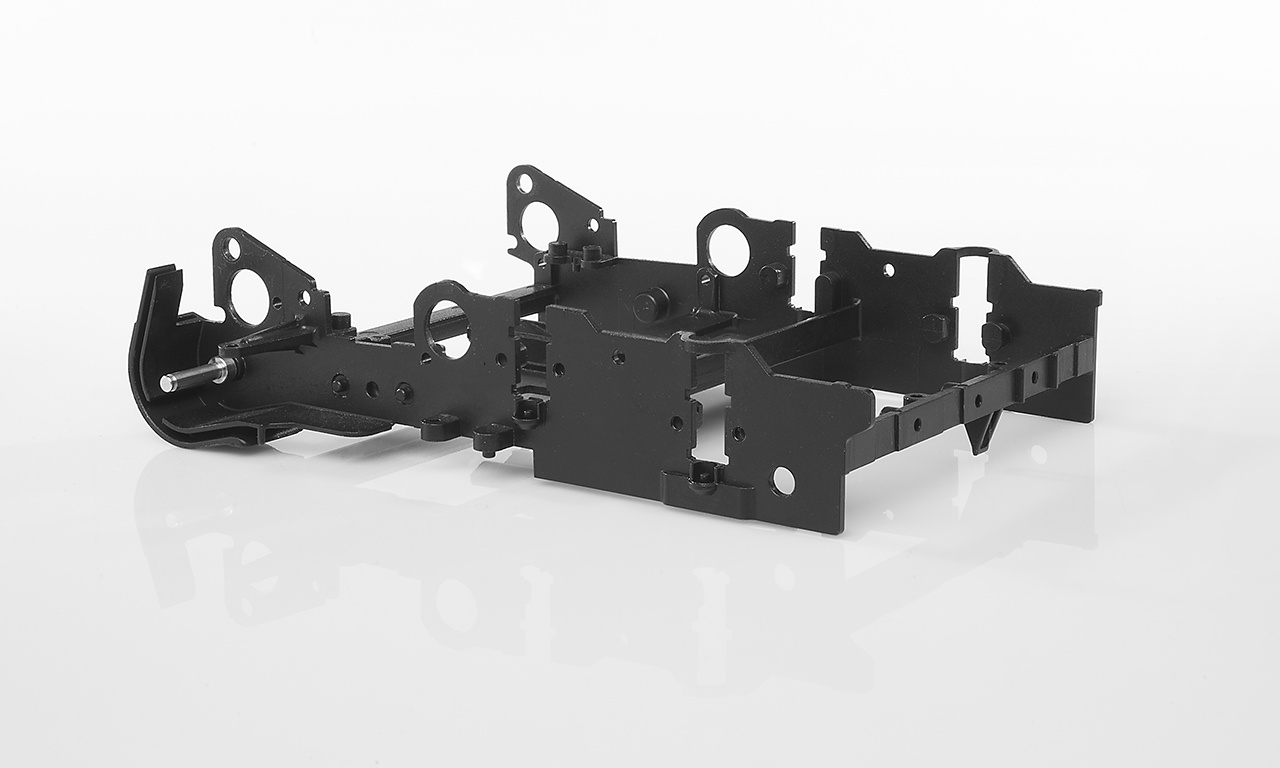

Automotive

Automotive is the industry in which die-casting technology is most frequently used. In the automotive industry, zinc alloys are chosen for their strength, ductility and malleability, that are impossible to obtain with other metals. The components of a car that can be made of zinc alloy are numerous: details of the interior, sunroof components, mechanical components, power steering and brake parts just to name a few.

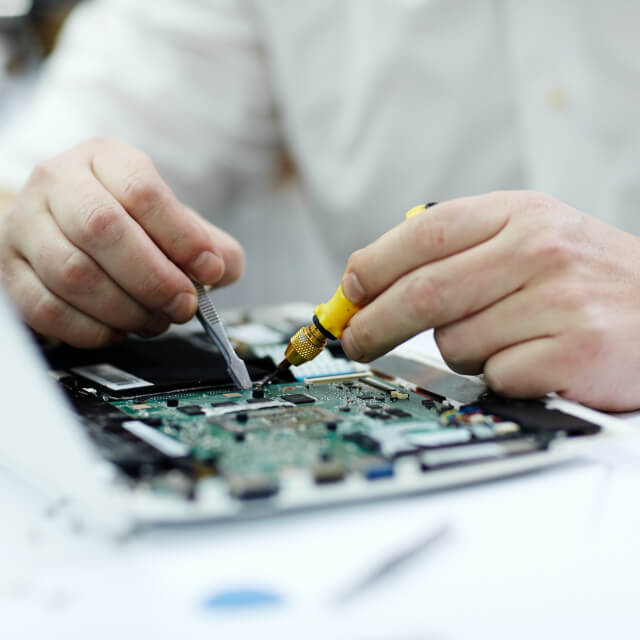

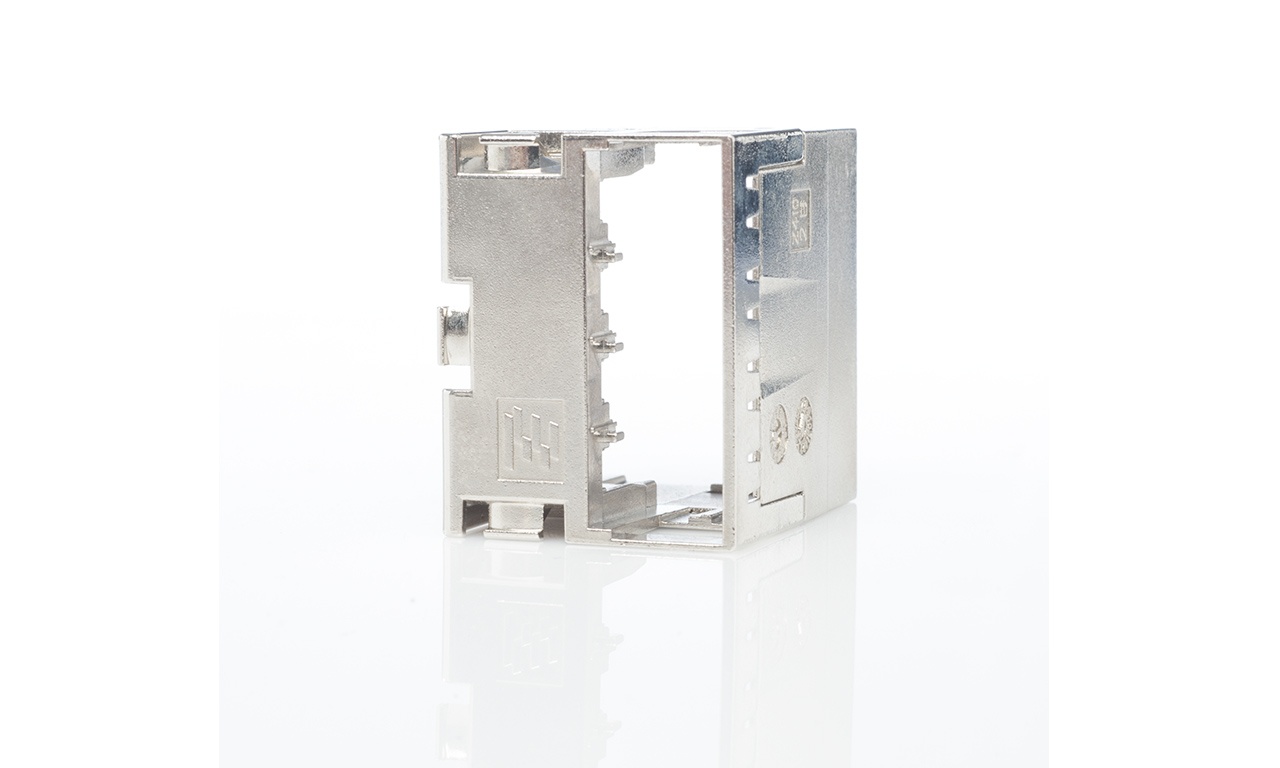

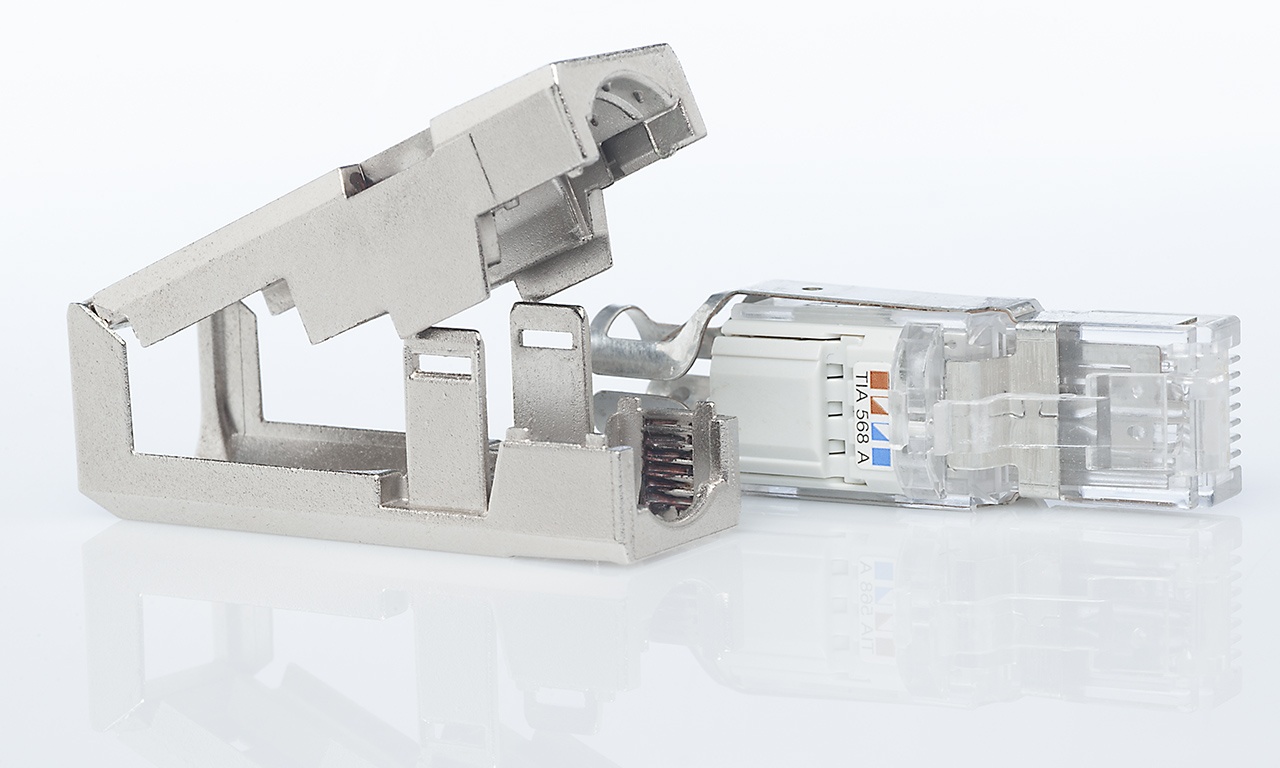

Electronics

Zamak products for electronics are particularly efficient and reliable. Made of a rigid and anti-vibration material, they are suitable for industrial and domestic applications. Other properties of Zamak make it extremely suitable for application in this industry, we are talking about the magnetic shielding property and the possibility of reaching extremely thin thicknesses that allow the creation of effective heat dissipation systems.

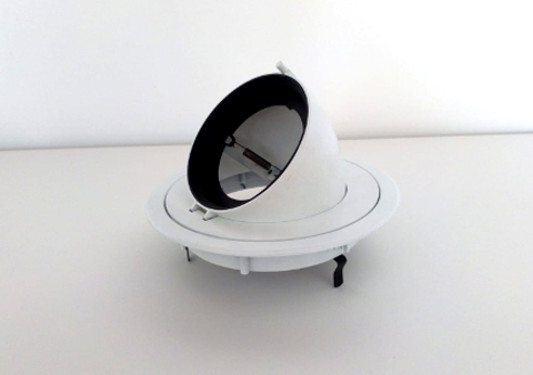

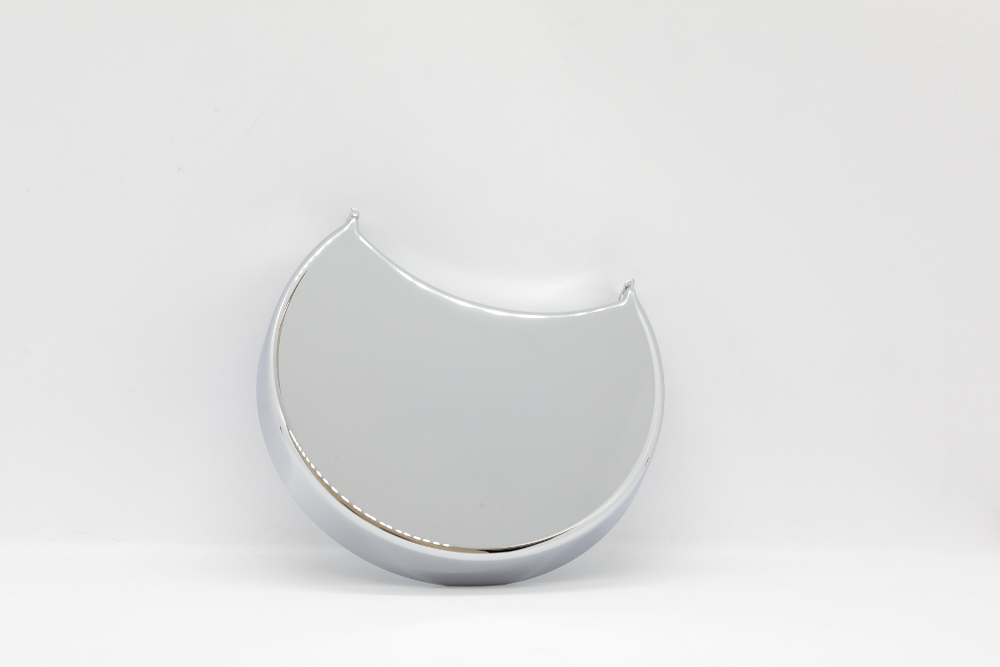

Lighting

The fluidity of Zamak makes it possible to create complex shapes and geometries with a high degree of detail, a characteristic of the material that allows designers a great creative freedom. Another differentiating feature in this industry is the possibility of carrying out different types of surface treatments on the components: liquid and powder coating, chrome plating and gold plating just to name a few. In this way, the Zamak components for lighting can harmoniously integrate with the different styles and environments of furniture.

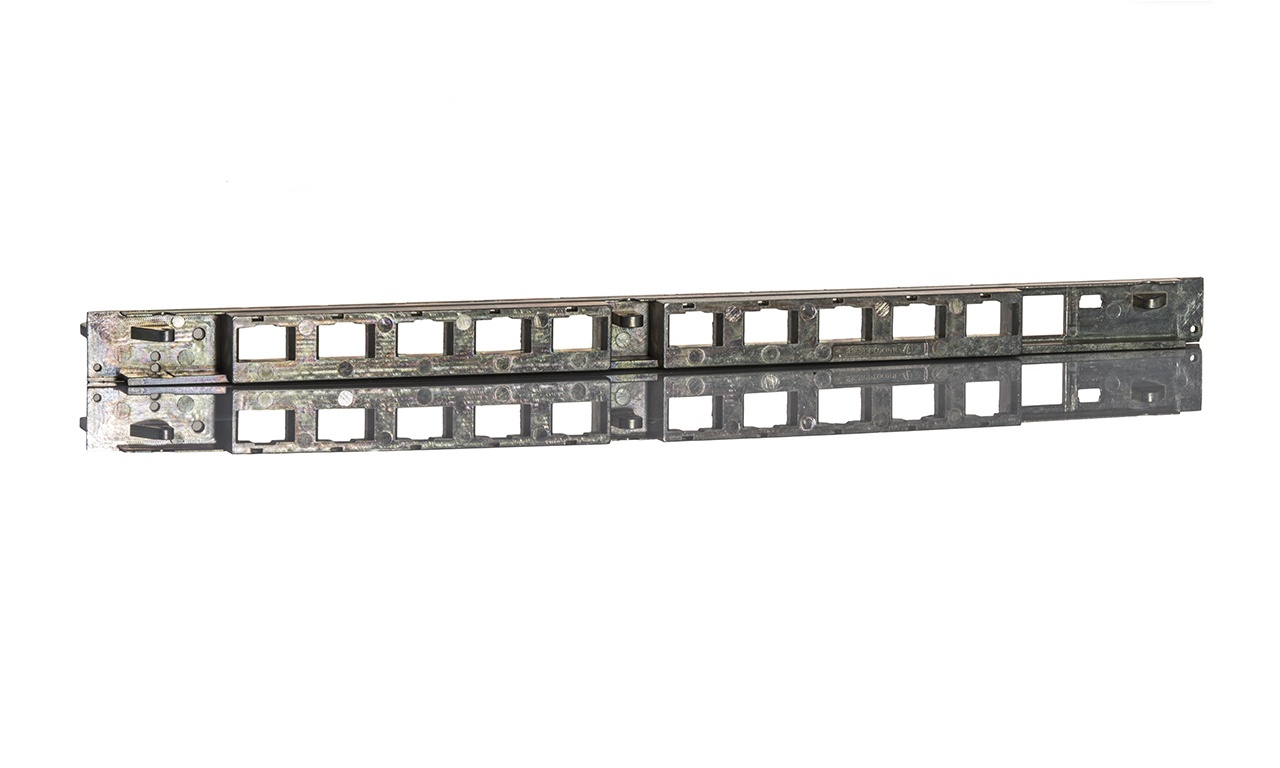

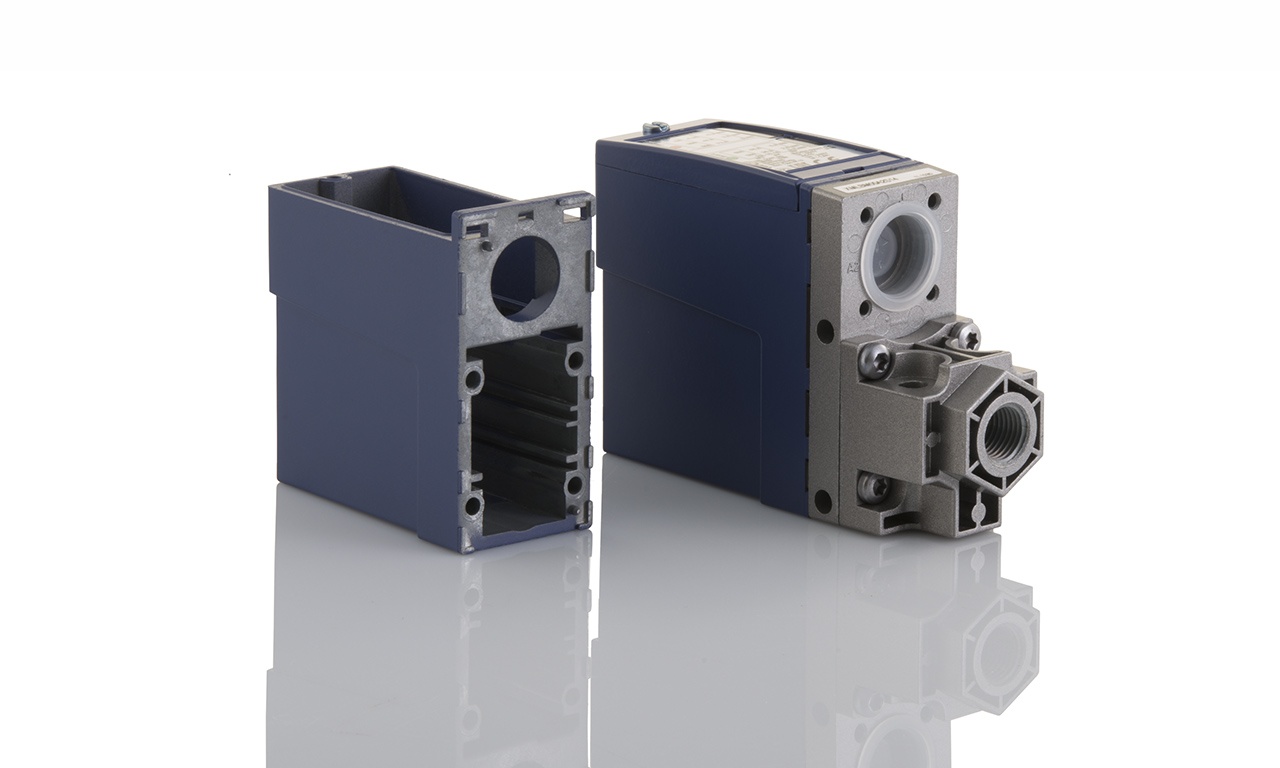

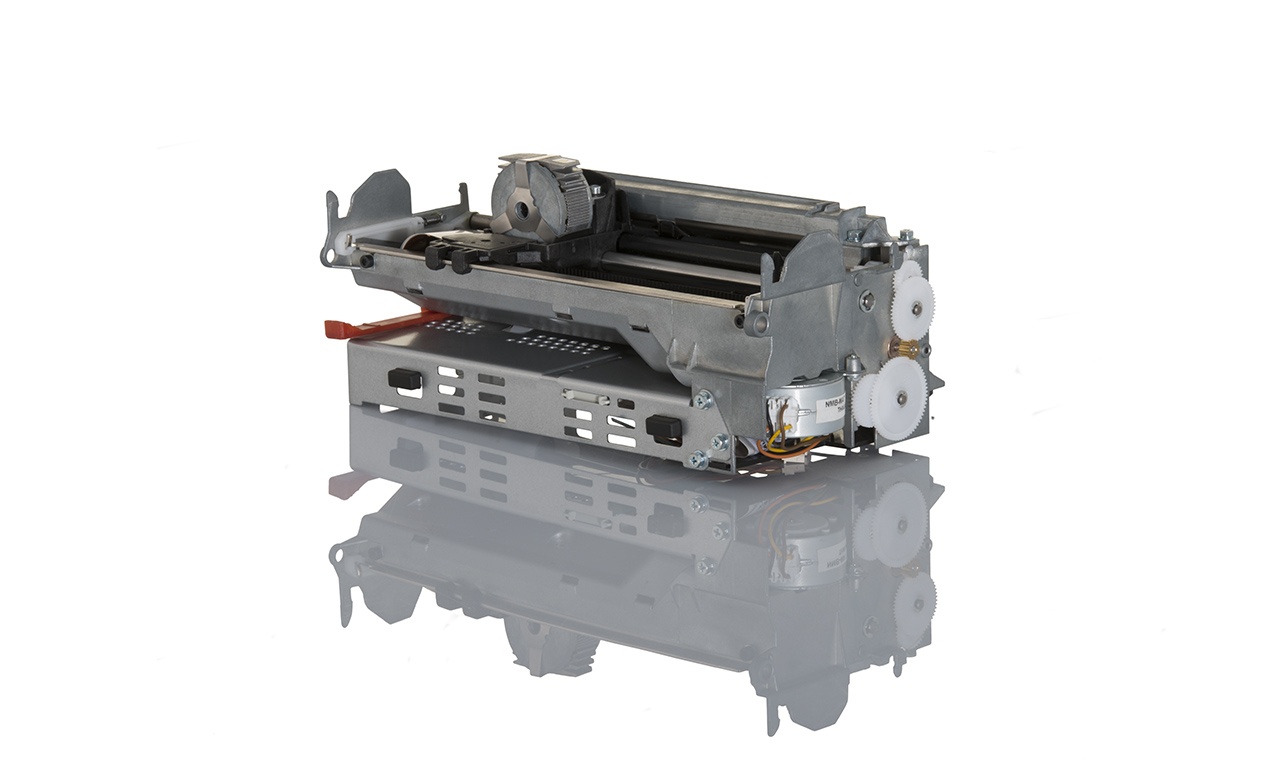

Electromechanical

Zamak articles for electromechanics have numerous properties that guarantee their operation in critical environments and with particular stresses and they are therefore particularly suitable for industrial applications. Resistance, hardness and rigidity, excellent surface quality, shielding against electromagnetic interference, anti-sparking properties and fluidity make the Zamak components for electromechanics suitable for performing mechanical and functional but also aesthetic and protective functions.

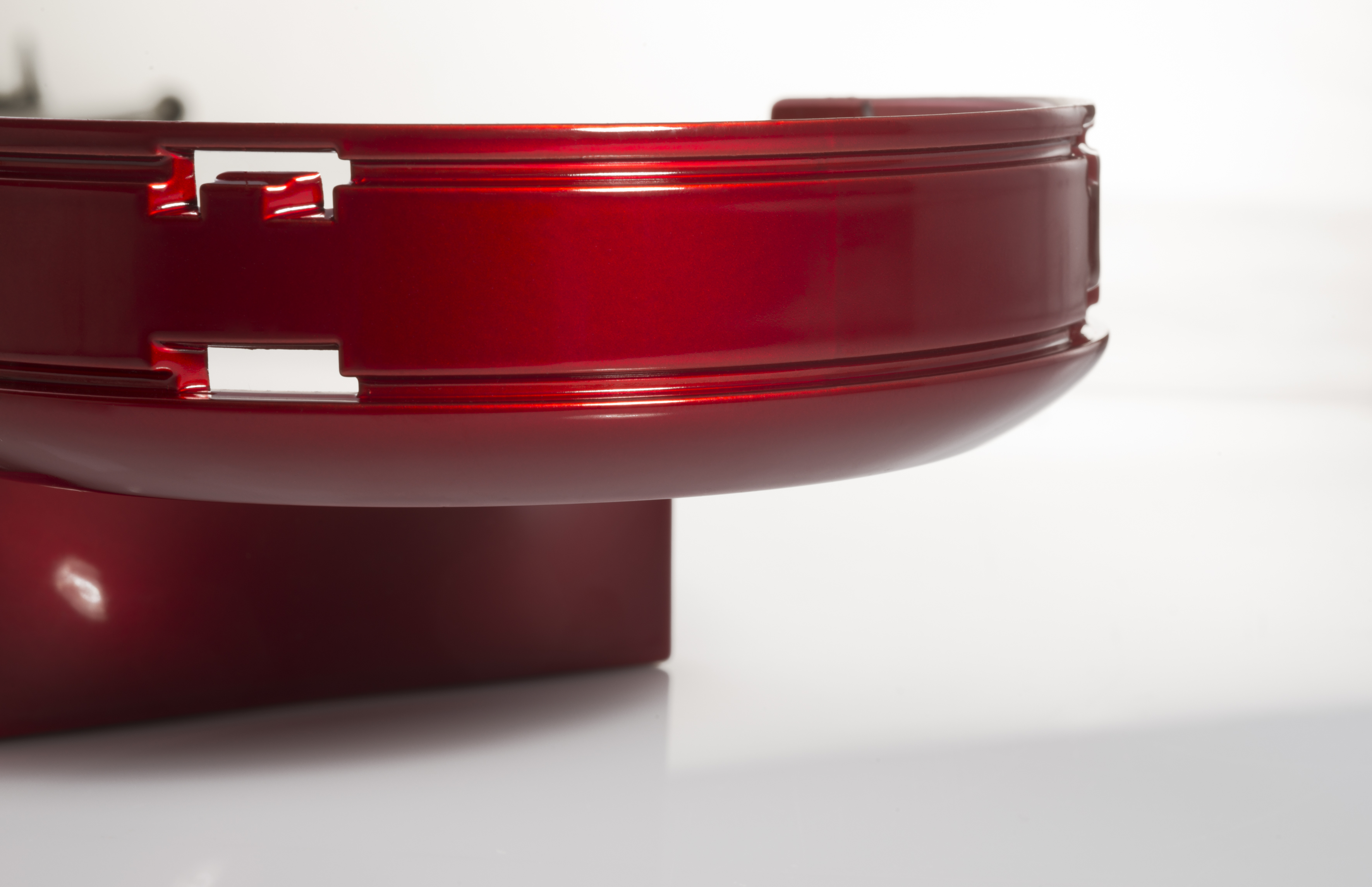

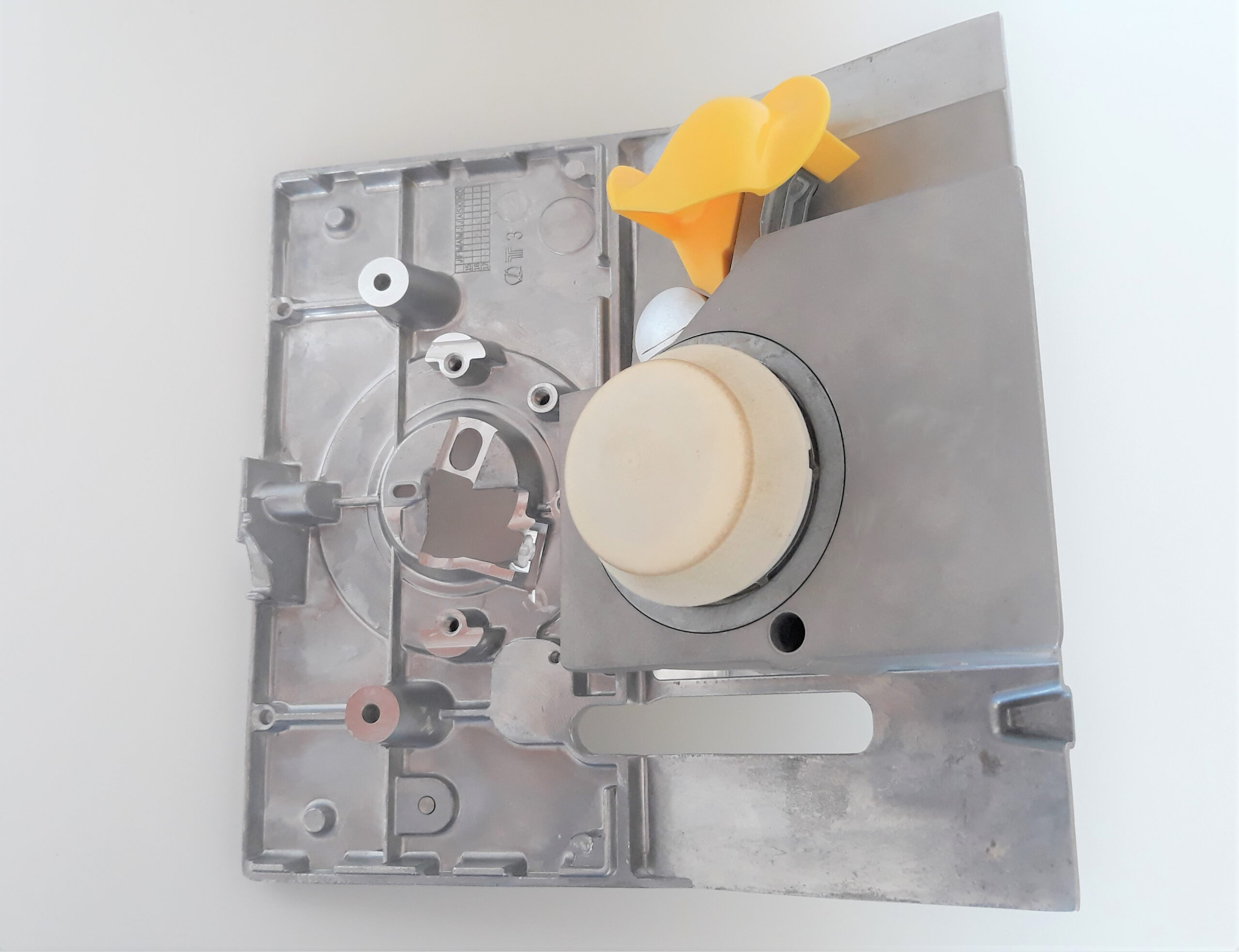

Small appliances & White Goods

Zamak components for household appliances and white goods have numerous advantages for both the manufacturer and the consumer. If for the consumer, aesthetic, quality, resistance, cleanliness and recyclability aspects are important on the producer side the added values are value is in the freedom of design and surface treatment, in the wide variety of finishing and assembly operations, in the reduction of costs allowed by the die-casting production process and in the co-design and implementation of the functional beauty of the components.

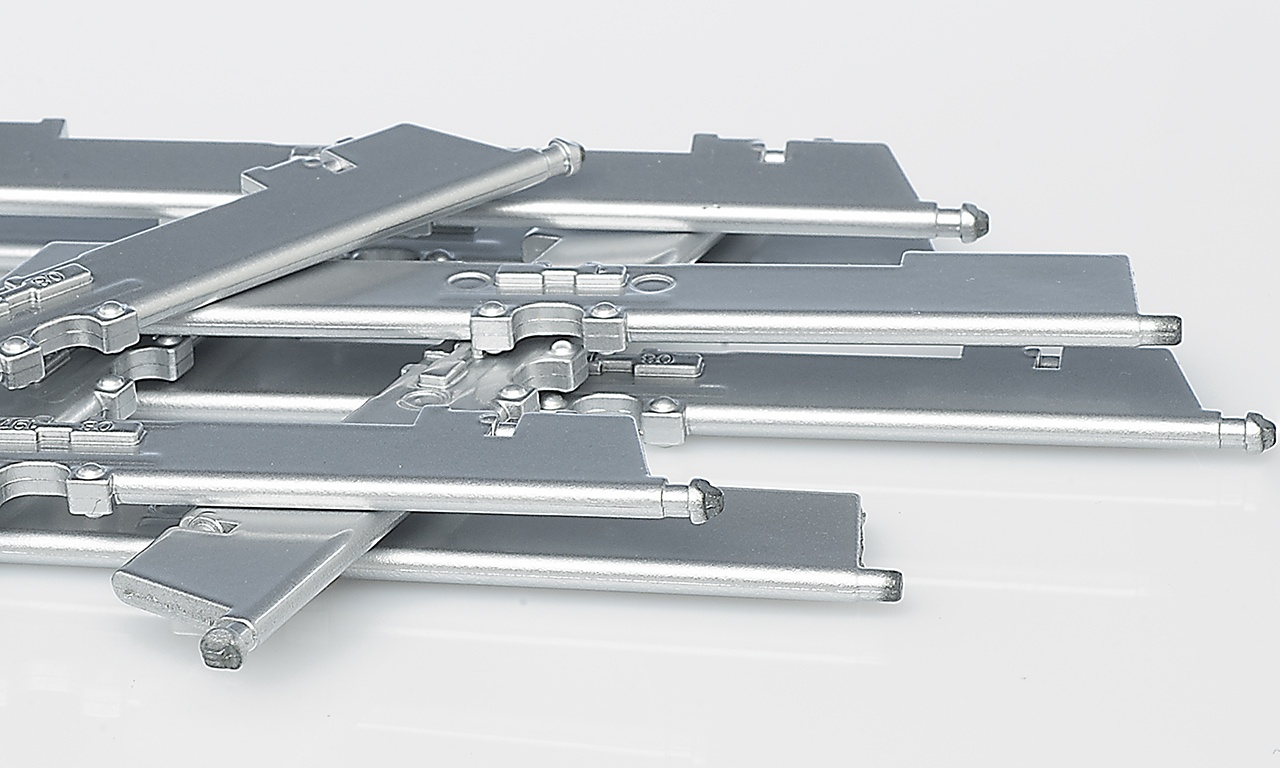

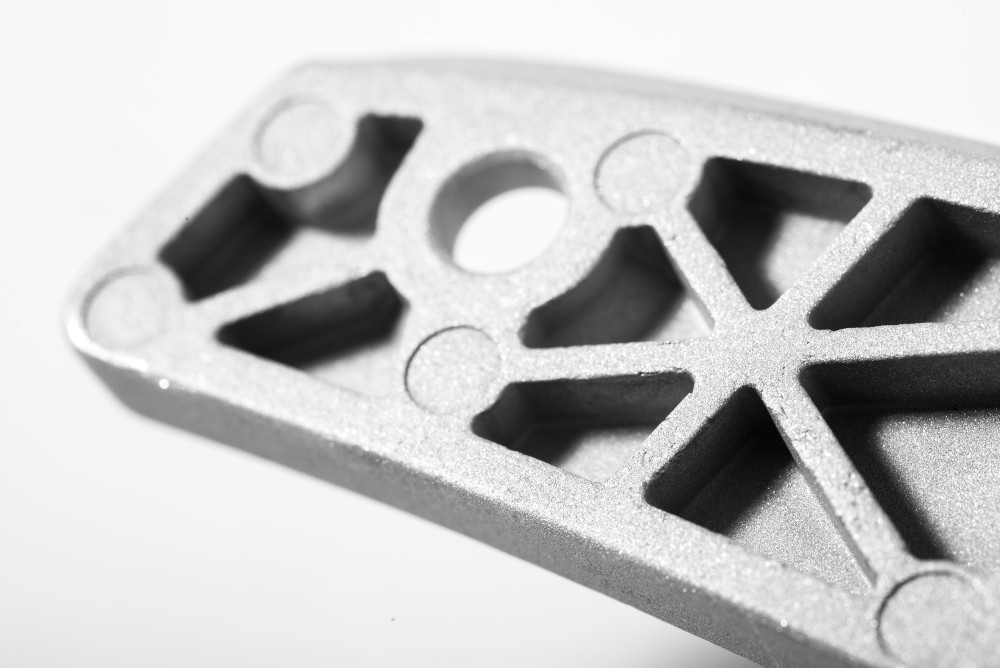

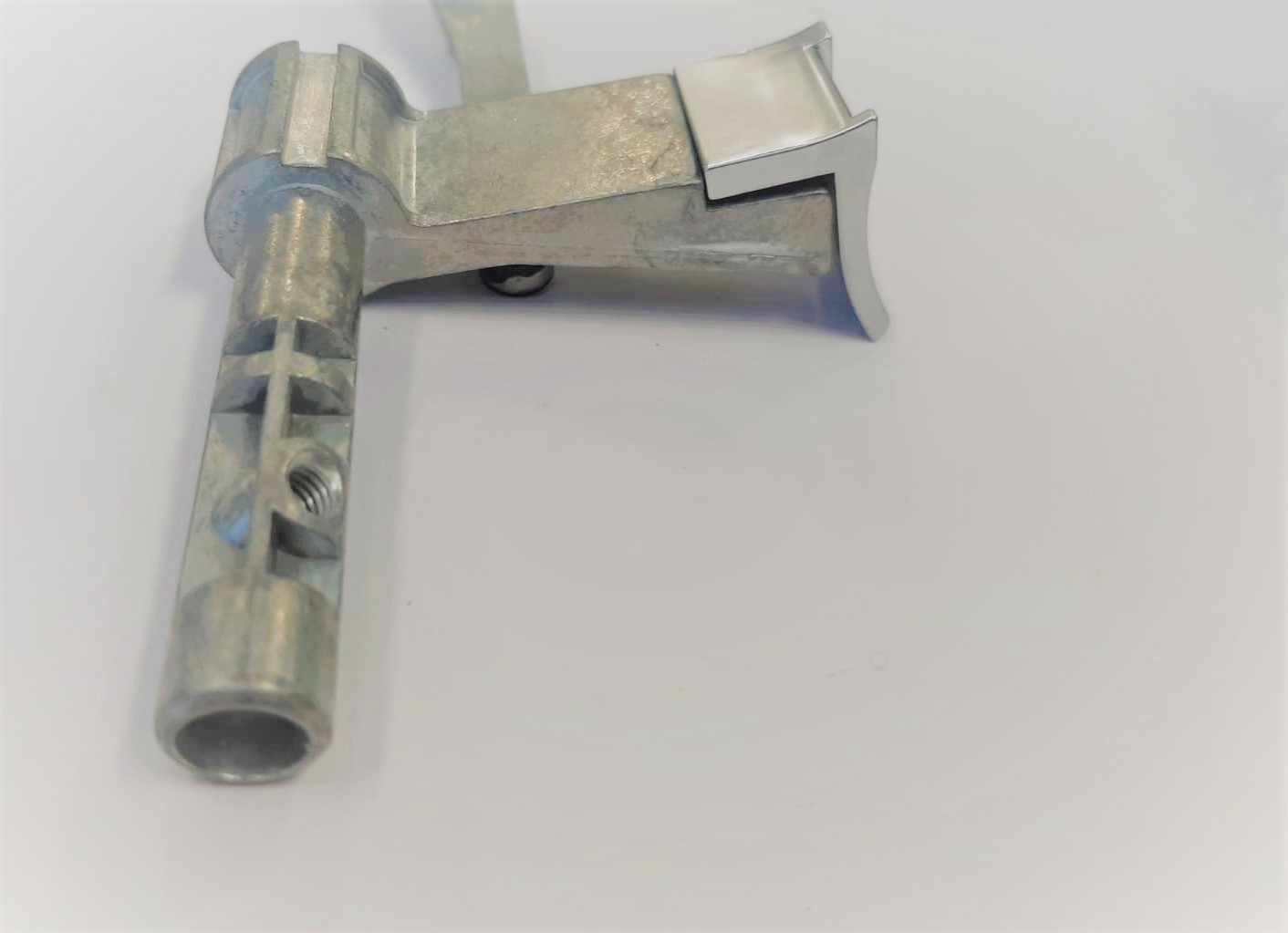

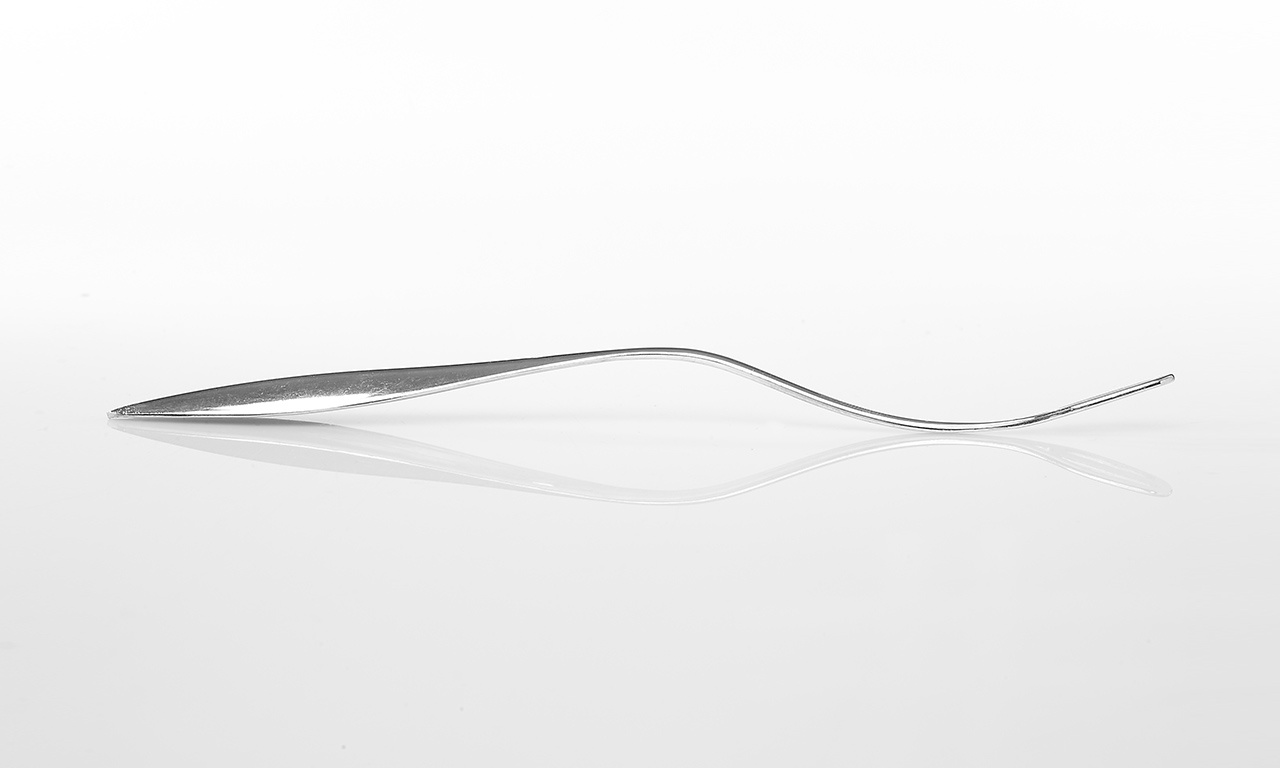

Textile

For machinery of the textile sector it is necessary to use high-performance components capable of meeting high technical and production requirements. The components in Zamak, characterized by anti- vibration properties and wear resistance, by an excellent surface quality and by the possibility of obtaining a high degree of detail and complex shapes directly during the die-casting production process, are particularly suitable and performing for applications in this industry.

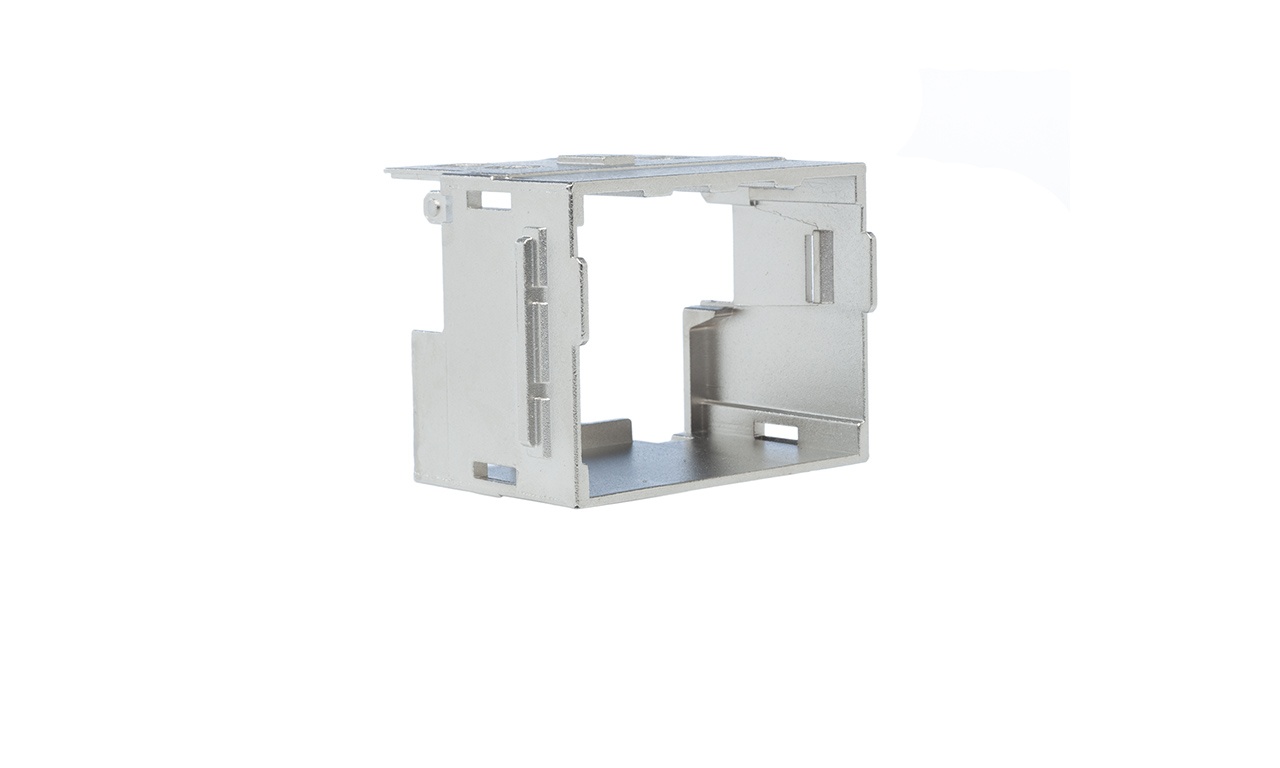

Building

In the building industry, components related to traditional construction and components with a higher rate of innovation and technology can be made of Zamak. For traditional construction are commonly made of Zamak elements of doors and windows, openings and air conditioners that are reliable, resistant and long lasting. In the field of home automation and associated technologies, Zamak is proving to be a particularly suitable material for the production of electronic locks and automatic openings.

Others

Zamak allows a great design freedom and it has properties that make it a material suitable for use in different and diversified industries. Over the years, Bruschi components have been used for the creation of objects intended for a wide range of uses: from personal care objects to innovative technological instruments. Each project is unique, with its own challenges and critical issues: Bruschi’s team of experts is always at the customer’s side to offer support in the industrialization of the products.