Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

Zinc alloys are renowned for their remarkable properties such as their robustness, resistance to corrosion and ease of casting. Over time, the evolution of manufacturing techniques has propelled zinc alloys to the forefront of a wide range of industries, including the automotive and electronics sectors. In this post, we will provide insights into the latest advancements unfolding within the realm of zinc alloys and their development, shifting from cutting-edge innovations to manufacturing breakthroughs.

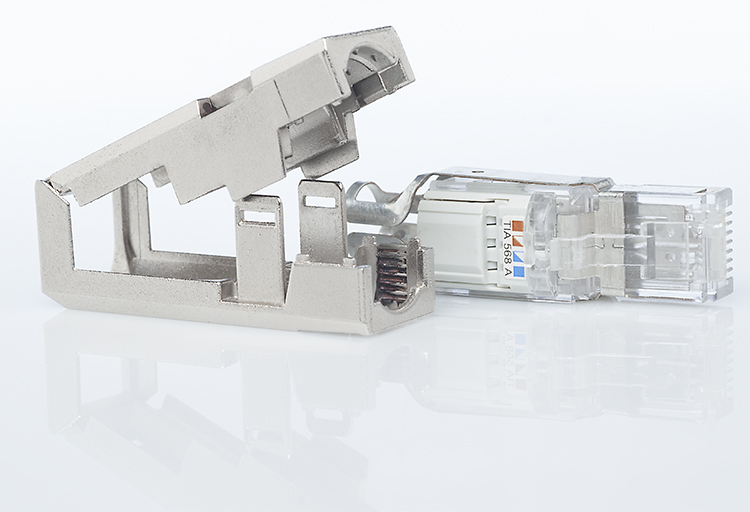

In the rapidly evolving world of electronics, manufacturers are constantly seeking innovative materials and manufacturing processes to enhance the performance of products, reduce costs and also improve the efficiency. One such technique that has gained prominence among different industries and also among the manufacturers is zinc die casting.

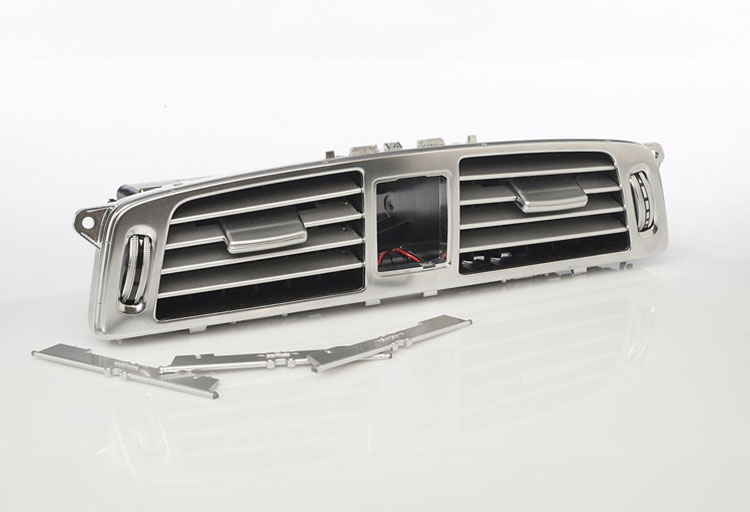

The automotive industry refers to the vast ecosystem of manufacturing, distribution, sales and consumption of vehicles designed for transporting people and goods. This industry includes a wide range of vehicle types that ranges from traditional internal combustion engine vehicles to the latest innovations in electric vehicles, autonomous vehicles and connected vehicles. The automotive market is not limited to the production of vehicles but it also includes associated services that are related to automotive industry such as aftermarket parts and solutions that support transportation needs all over the globe. The automotive market stands as one of the most influential sectors globally that is shaping economies, societies and individual lifestyles.

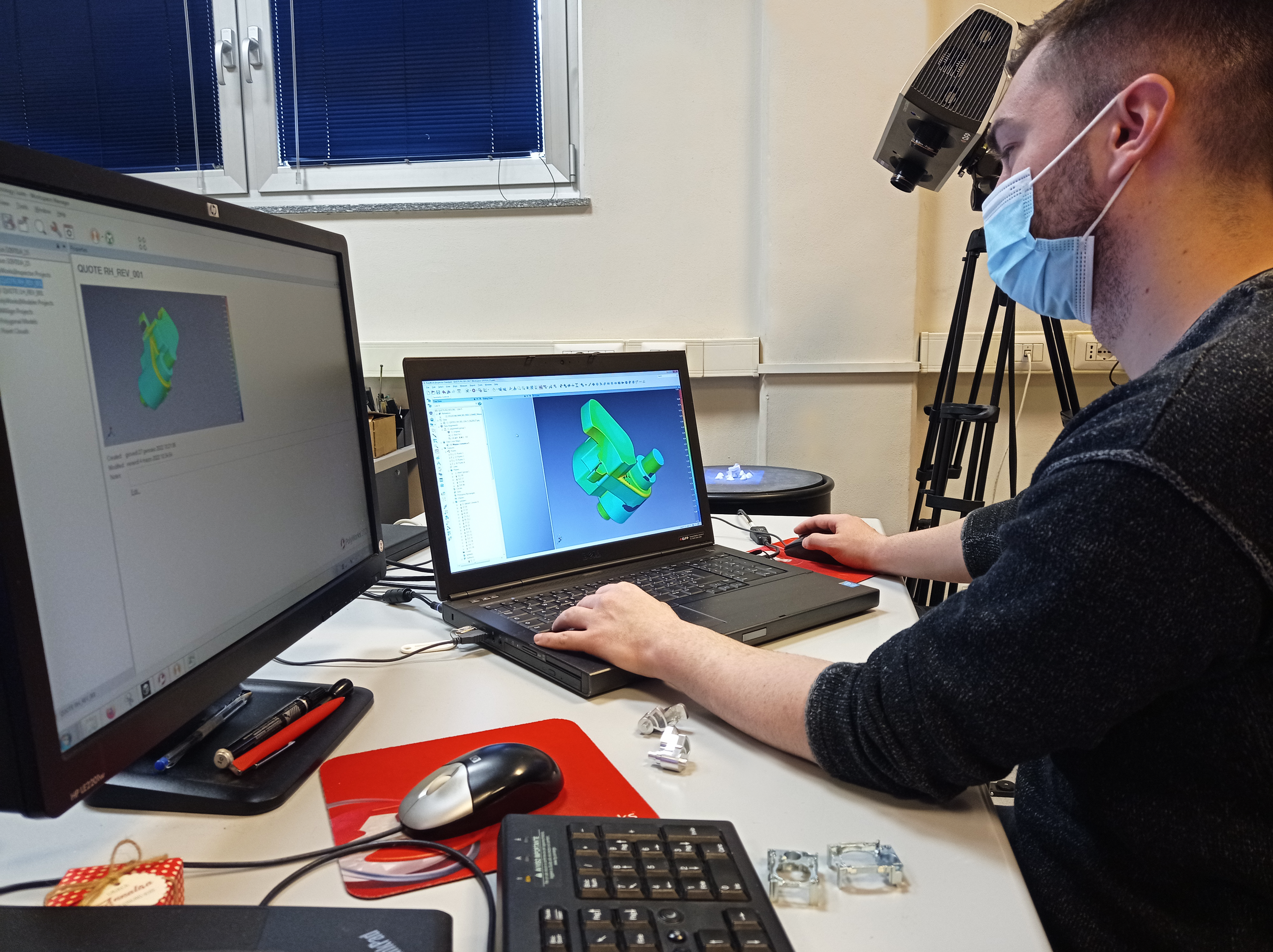

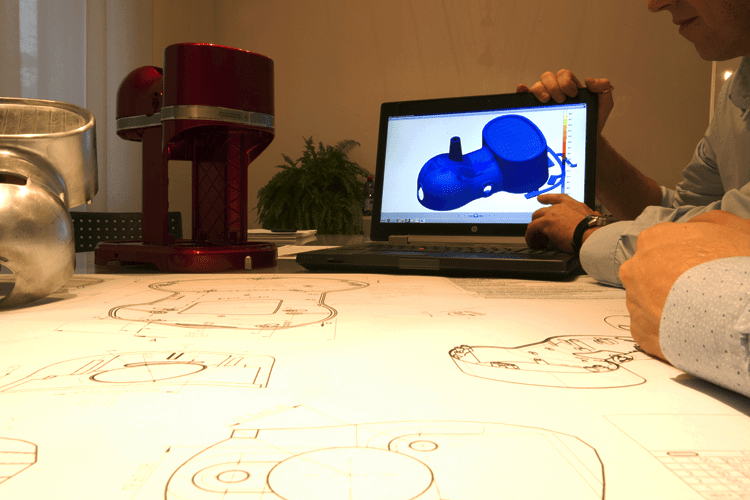

Zinc alloy die casting is a versatile and reliable manufacturing technology that enables the creation of complex components with high precision and strength for a wide range of industries. A crucial aspect of the production of zinc die-cast parts is the possibility of obtaining complex shapes adapted to modern design requirements, allowing for a harmonious balance between form and function to be achieved. In this post, we will explore the importance of achieving design excellence in zinc die casting and see how functional design can positively influence the success of a product.

Of all the modern manufacturing methods available today, the zinc alloy die-casting process proves to be one of the most efficient and environmentally friendly processes. In fact, these alloys offer numerous advantages in terms of environmental and economic sustainability, which we will see below.

In this post, we will address the main problems concerning the possible casting defects that could arise in the die-casting process and which would compromise the success of subsequent surface treatment. This treatment, which can be a galvanic or a painting, can be carried out for aesthetic and functional reasons.

Zinc alloys are an excellent choice for creating and manufacturing appliance components. This blog post will explain why zinc alloys are widely used in this sector, highlighting their aesthetic, functional, environmental, and economic advantages.

Cavitation is a form of mold erosion that occurs during casting. In some critical areas of the dies, steel is removed and eroded by an aggression generated by micro-implosions of gases and vapors that occur during the filling of the cavity.

The rapid deterioration of the dies results in production stoppages and major maintenance operations that compromise the production efficiency.

In terms of mechanical strength, the breaking load is commonly defined as ultimate tensile stress (UTS), which is the maximum external force limit applied beyond which a material loses its functional specifications in terms of strength. Tensile strength tests vary according to the type of stress the material is subjected to, which we will describe later. In our case, are tests to be carried out on a component during production.

Zinc die casting is a process that consists in injecting the liquid metal under pressure into a mould, generally made of special steel, and letting it solidify. The die casting technique is the shortest way that leads from the metal in the liquid state to the finished product and has different fields of application (automotive above all, but also electronics, electromechanics, household appliances and in general all sectors that require non-ferrous metallic components).