All the posts for cost-reduction

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

Of all the modern manufacturing methods available today, the zinc alloy die-casting process proves to be one of the most efficient and environmentally friendly processes. In fact, these alloys offer numerous advantages in terms of environmental and economic sustainability, which we will see below.

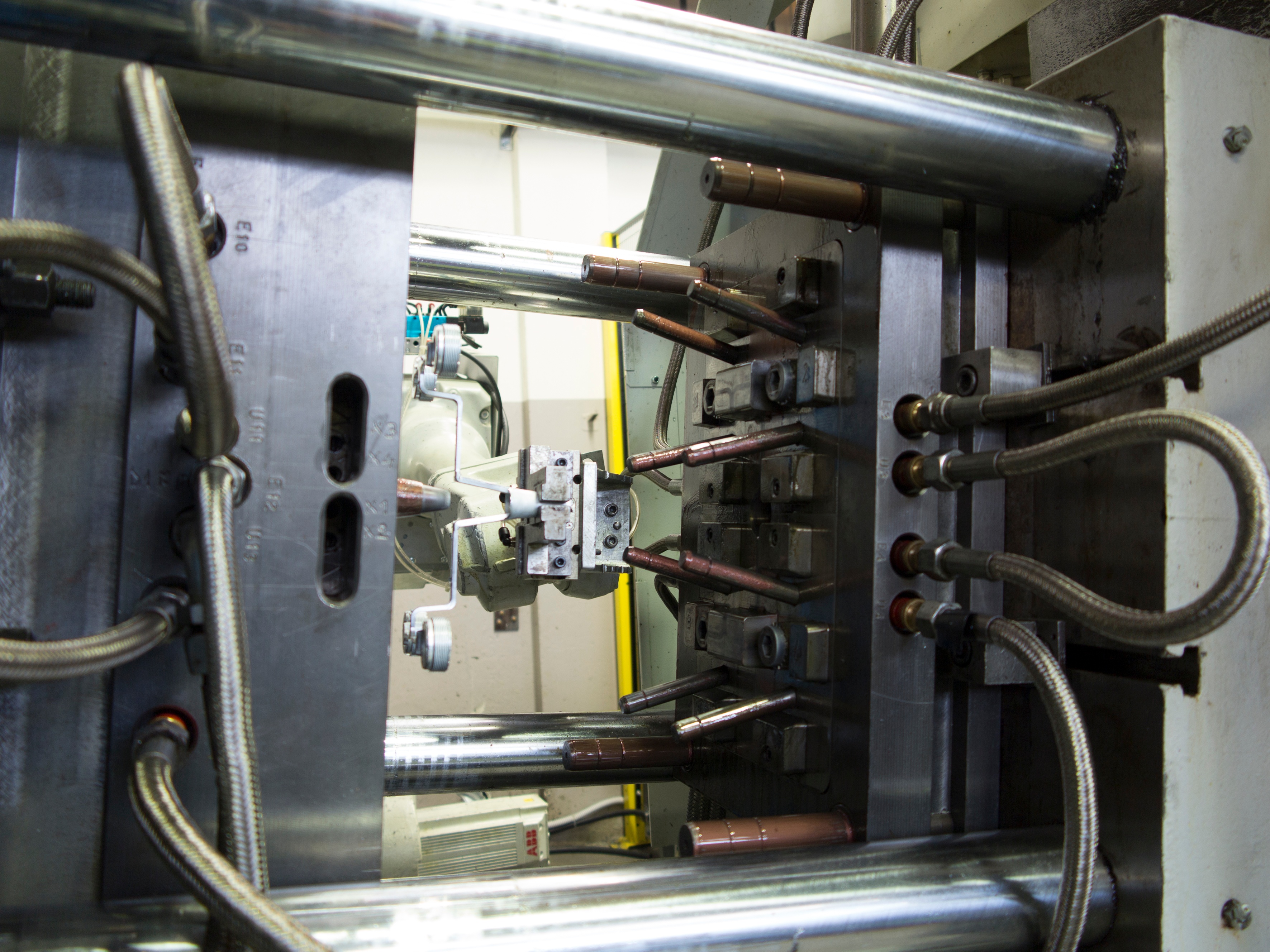

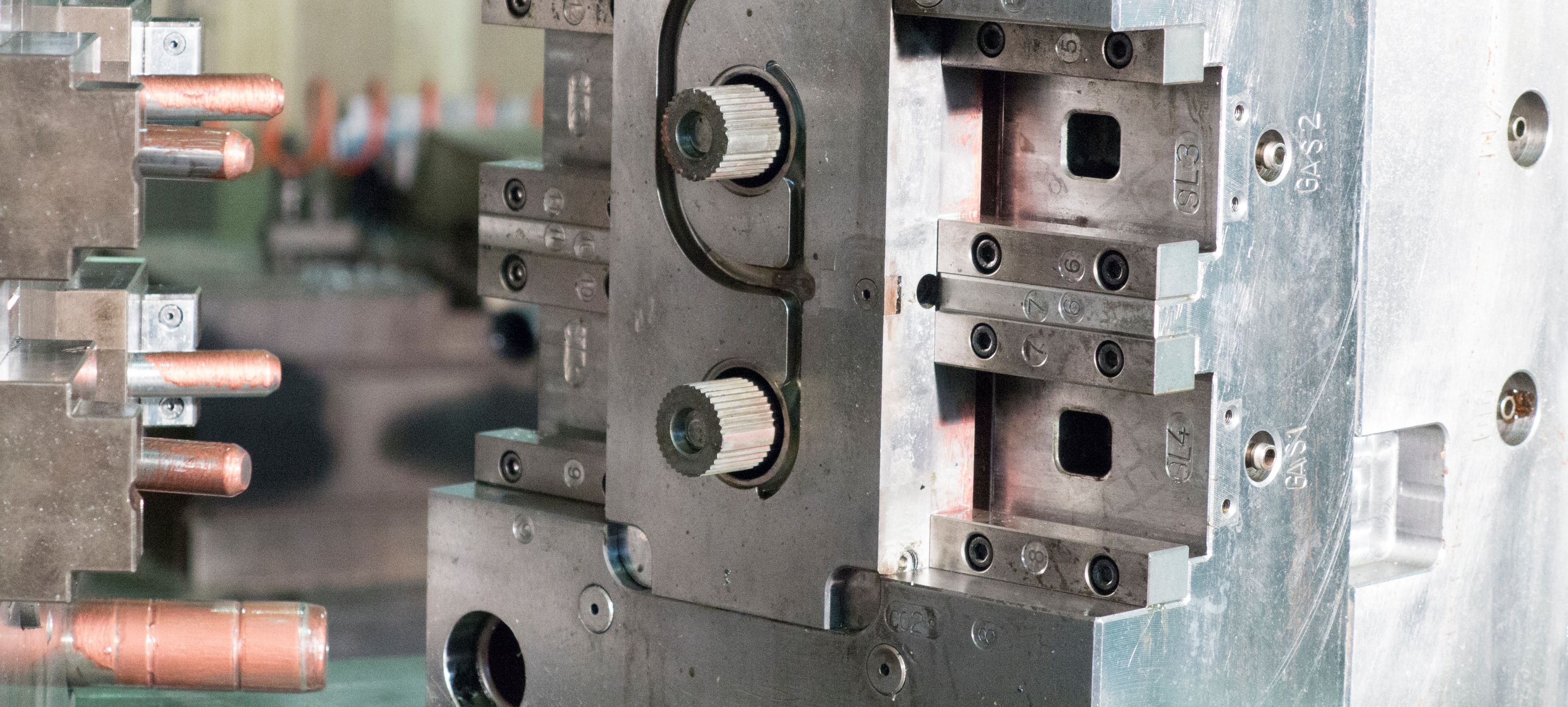

This post deals with the fundamentals of die casting machines and their role in the whole die casting process. Moreover, the post gives an outlook on the sector's future perspectives.

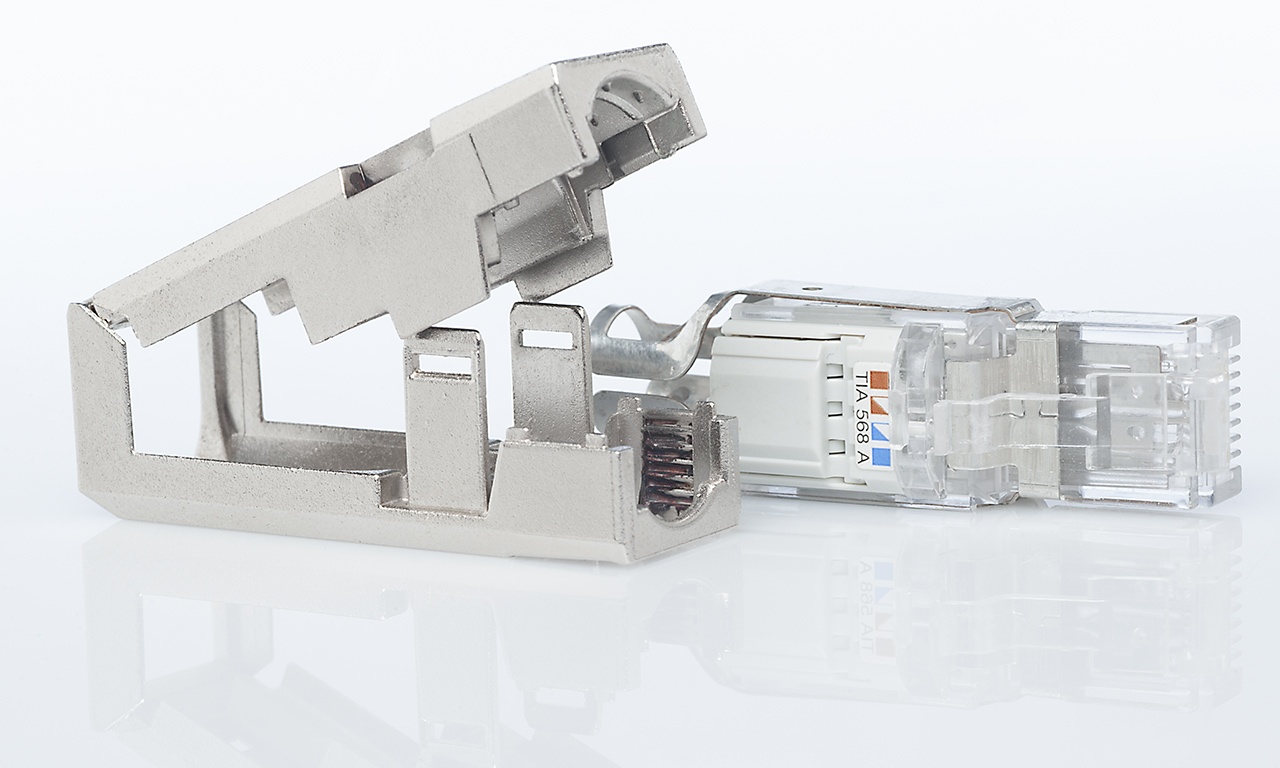

In this post we are going to briefly analyze the characteristics of zamak and to highlight its advantages in the production of components for electronic products. After that, we will review some components explaining how choosing zamak has made them more beneficial compared with similar products manufactured with other materials.

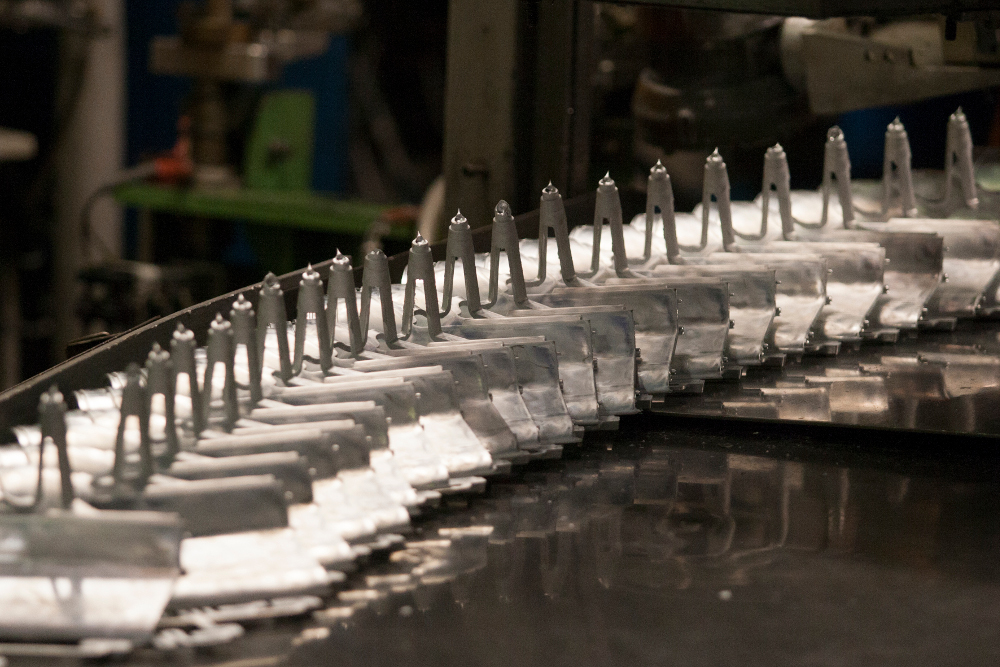

Cost reduction in zinc die casting is an activity that shall be executed without affecting the quality and functionality of the component that is produced. All the activities that aim to increase productivity, to diminish scrap rate and to simplify productive processes, as well as the choices of materials and processing, are cost reduction strategies.

Zinc alloys are a material that, if employed in die casting, allows the achievement of products with thin wall thickness. This property of zinc alloys results in an important added value because it permits the production of components with reduced weight and dimensions, thus benefiting from cost and raw material saving.

Process improvement, in the zinc die casting industry as well as in many other manufacturing sectors, consists of a series of actions undertaken to enhance production times, to reduce costs and, consequently, to obtain results that satisfy client’s requests in terms of timing and performance.

In this post we are going to discuss the advantages of involving suppliers in procurement strategy, and how they can impact the final result of a VA/VE analysis.

In this post we are going to explain what Value Analysis / Value Engineering is, starting from its history up to why it is so important for manufacturers today.

In this post we are going to discuss the structure of die casting cycle time and how its optimization can bring various benefits for the company.

In this post we are going to describe in detail the relation between mold maintenance department and foundry: how the inclusion of maintenance department and tooling department in the production area can bring actual economic advantages and time saving.