All the posts for product-design

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

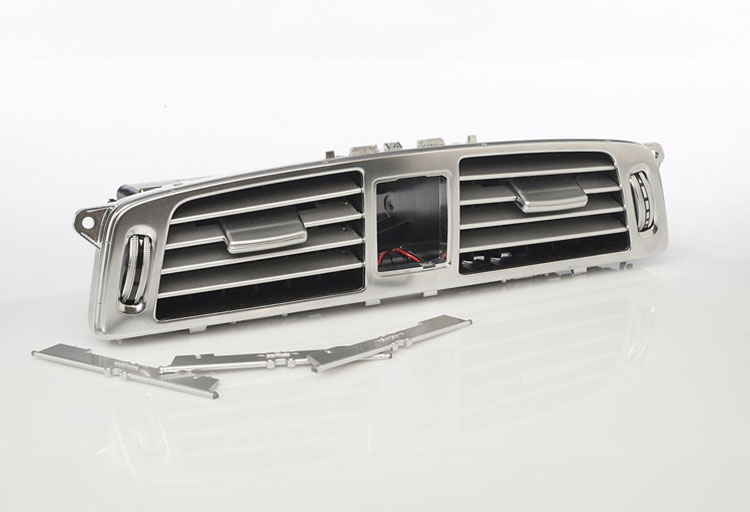

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

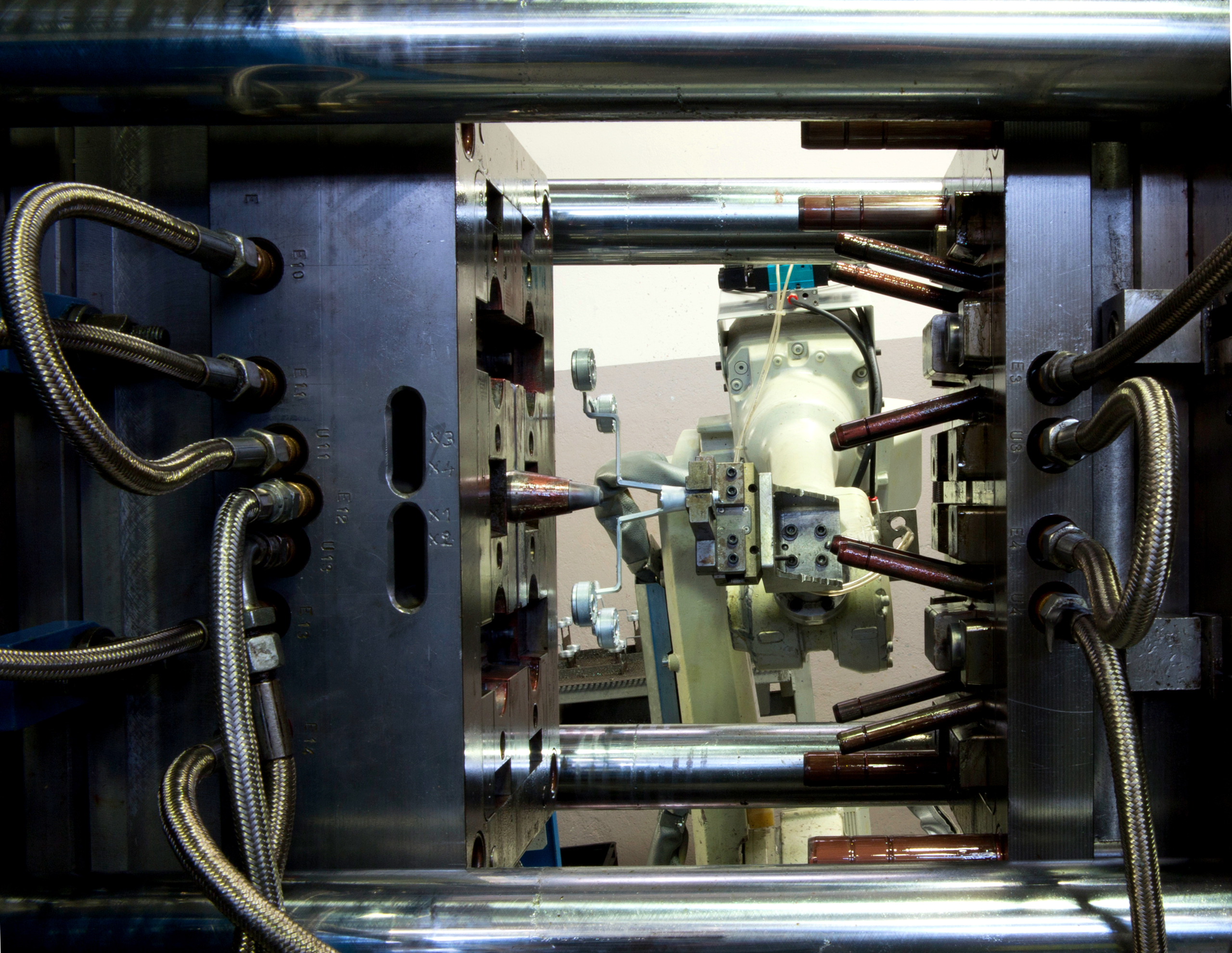

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

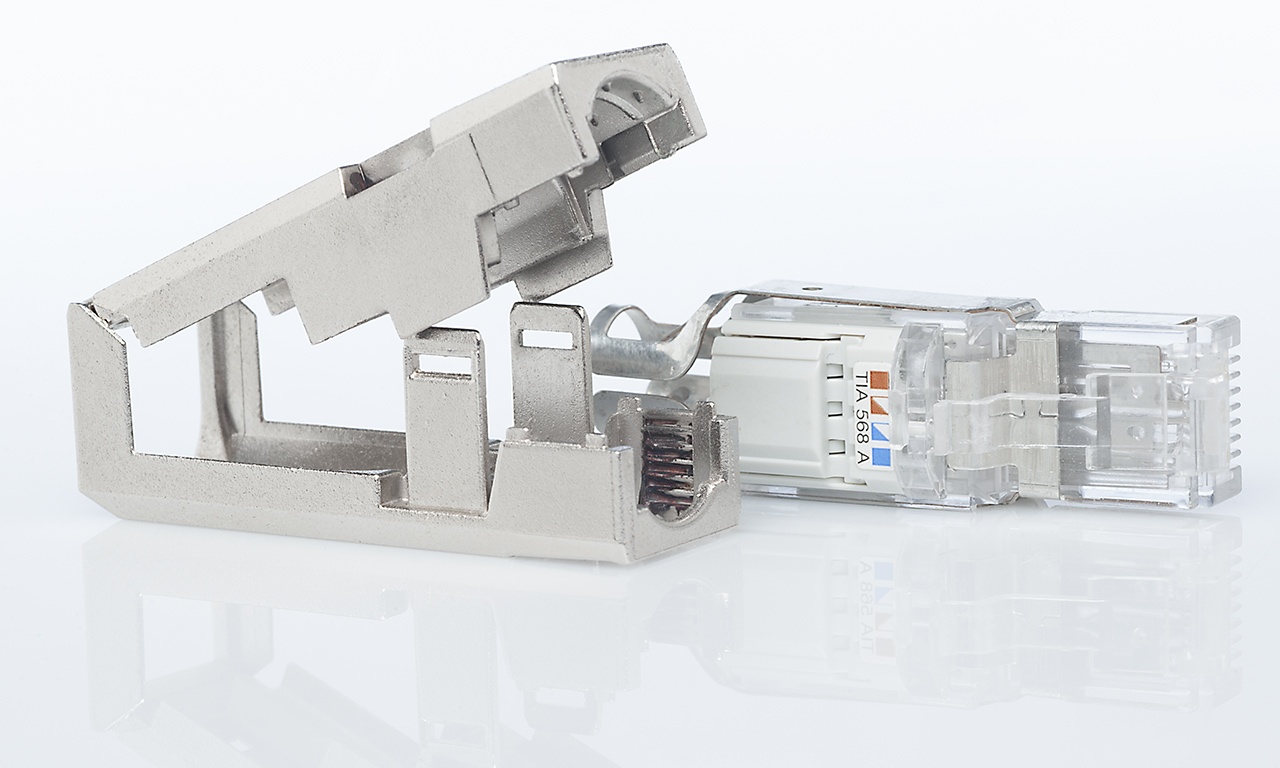

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

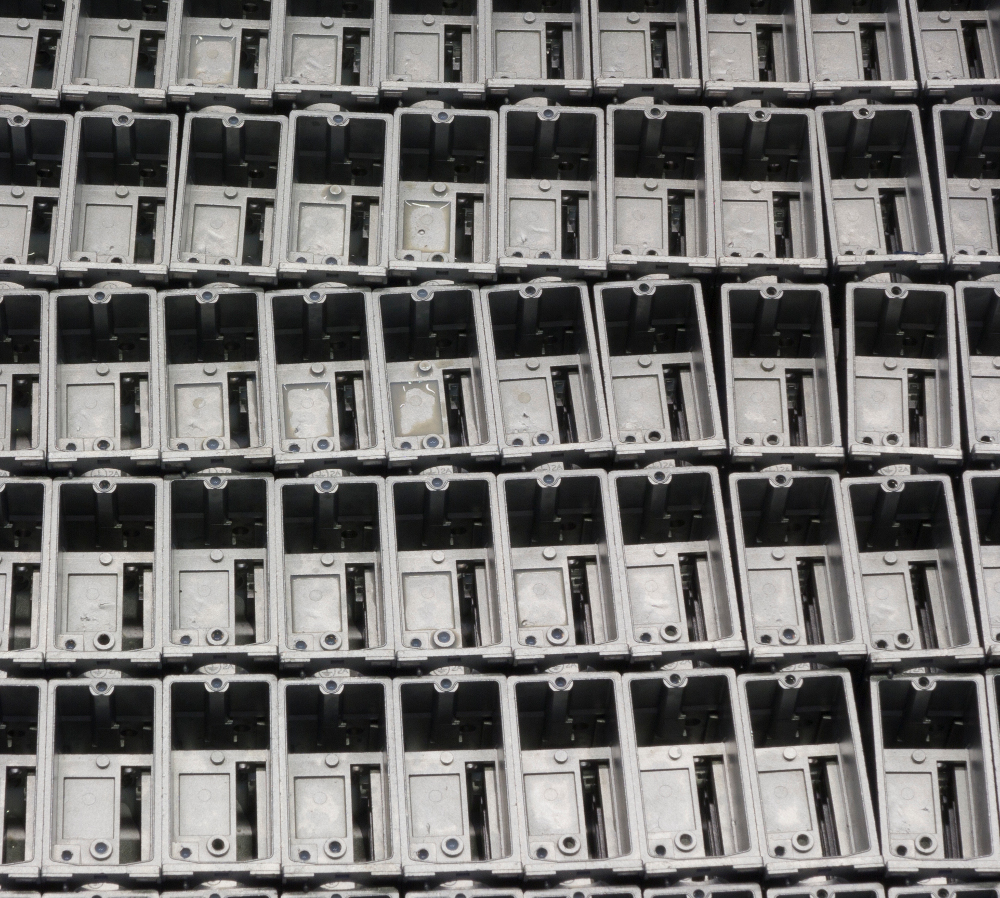

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

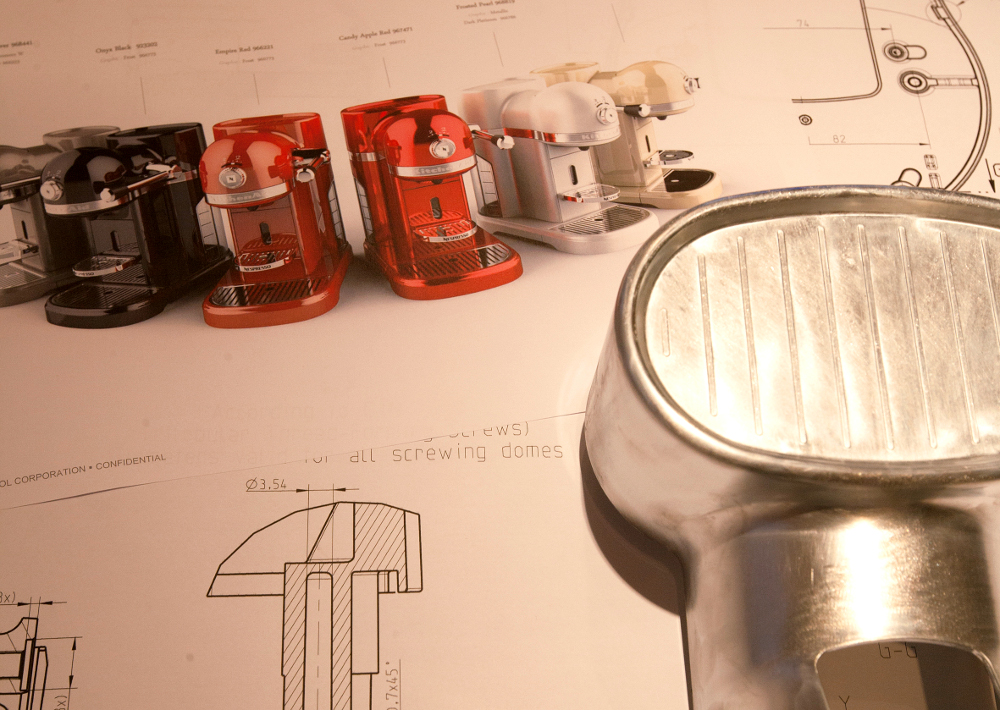

Zinc alloy die casting is a versatile and reliable manufacturing technology that enables the creation of complex components with high precision and strength for a wide range of industries. A crucial aspect of the production of zinc die-cast parts is the possibility of obtaining complex shapes adapted to modern design requirements, allowing for a harmonious balance between form and function to be achieved. In this post, we will explore the importance of achieving design excellence in zinc die casting and see how functional design can positively influence the success of a product.

In this post we are going to briefly analyze the characteristics of zamak and to highlight its advantages in the production of components for electronic products. After that, we will review some components explaining how choosing zamak has made them more beneficial compared with similar products manufactured with other materials.

Industrialization of the product is a very delicate phase in the process of production of zinc alloy die casts: in fact it is in this phase that, after receiving the order from the customer, all the procedures that are necessary to start mass production are defined.

In this post we are analyzing how the qualities of zinc alloys become important competitive advantages in the production of lighting components. We will then review some products and their characteristics as case studies.

In this post we are going to analyze a case study that explains how to reduce casting defects through mold design. Due to mold wear condition components started to show superficial defects: Bruschi engineers have thus introduced improvements in order to reduce casting defects.

The term product design defines the process of designing a new product that has to be marketed in a specific business, taking into account not only its aesthetical characteristics but also its functions and its production cycle. Indeed, the product must meet the final user expectations while simultaneously be compliant with the production process.