All the posts for die-casting

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

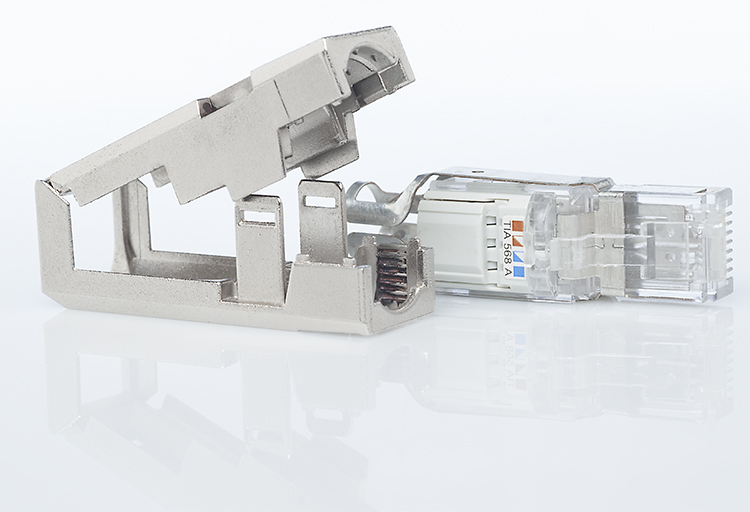

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

Zinc alloys are renowned for their remarkable properties such as their robustness, resistance to corrosion and ease of casting. Over time, the evolution of manufacturing techniques has propelled zinc alloys to the forefront of a wide range of industries, including the automotive and electronics sectors. In this post, we will provide insights into the latest advancements unfolding within the realm of zinc alloys and their development, shifting from cutting-edge innovations to manufacturing breakthroughs.

In the rapidly evolving world of electronics, manufacturers are constantly seeking innovative materials and manufacturing processes to enhance the performance of products, reduce costs and also improve the efficiency. One such technique that has gained prominence among different industries and also among the manufacturers is zinc die casting.

The automotive industry refers to the vast ecosystem of manufacturing, distribution, sales and consumption of vehicles designed for transporting people and goods. This industry includes a wide range of vehicle types that ranges from traditional internal combustion engine vehicles to the latest innovations in electric vehicles, autonomous vehicles and connected vehicles. The automotive market is not limited to the production of vehicles but it also includes associated services that are related to automotive industry such as aftermarket parts and solutions that support transportation needs all over the globe. The automotive market stands as one of the most influential sectors globally that is shaping economies, societies and individual lifestyles.

Zinc die casting is a process that consists in injecting the liquid metal under pressure into a mould, generally made of special steel, and letting it solidify. The die casting technique is the shortest way that leads from the metal in the liquid state to the finished product and has different fields of application (automotive above all, but also electronics, electromechanics, household appliances and in general all sectors that require non-ferrous metallic components).

In this post we are analyzing how the qualities of zinc alloys become important competitive advantages in the production of lighting components. We will then review some products and their characteristics as case studies.

In this article, after briefly depicting the hierarchical structure of the automotive industry and the reference standard for the Tiers of different levels, we analyze the special partnership that exists between a Tier 2 automotive supplier and its customers, specifically examining the relationship of trust that can be established between a Tier 1 and a SME (Small and Medium Enterprises) Tier 2 automotive supplier.

Thanks to their excellent mechanical and physical properties zinc alloys are a perfect material for die casting: they are indeed resistant, fluid, durable and rigid. But which are the best zinc alloys for hot chamber die casting? In this post we are going to analyze the different characteristics of zinc alloys for hot chamber die casting in order to define the best choice on the basis of the features that the final product requires.

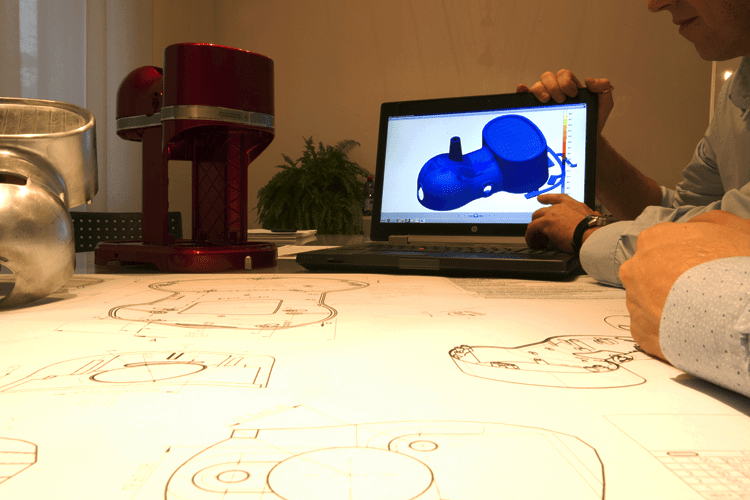

In this post we are going to describe the business philosophy of functional beauty. Starting from this philosophy, Bruschi created Nespresso KitchenAid Artisan 5KES0503, a design coffee machine that led the company to the victory of the prestigious European Zinc Die Casting Competition for design in 2016.

The process of zinc die casting is highly popular for making parts in building and industrial fields, but its most common application is in automotive industry. In fact, cars have different parts that can be crafted through die casting, so much that the modern process of die casting originally started for automotive industry.

ZAMAK molding is the creation of components using zinc alloys for die casting. In this post we are going to discuss how the choice of the alloy can affect the final result of hot chamber die casting.