All the posts for automation

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

The automotive industry refers to the vast ecosystem of manufacturing, distribution, sales and consumption of vehicles designed for transporting people and goods. This industry includes a wide range of vehicle types that ranges from traditional internal combustion engine vehicles to the latest innovations in electric vehicles, autonomous vehicles and connected vehicles. The automotive market is not limited to the production of vehicles but it also includes associated services that are related to automotive industry such as aftermarket parts and solutions that support transportation needs all over the globe. The automotive market stands as one of the most influential sectors globally that is shaping economies, societies and individual lifestyles.

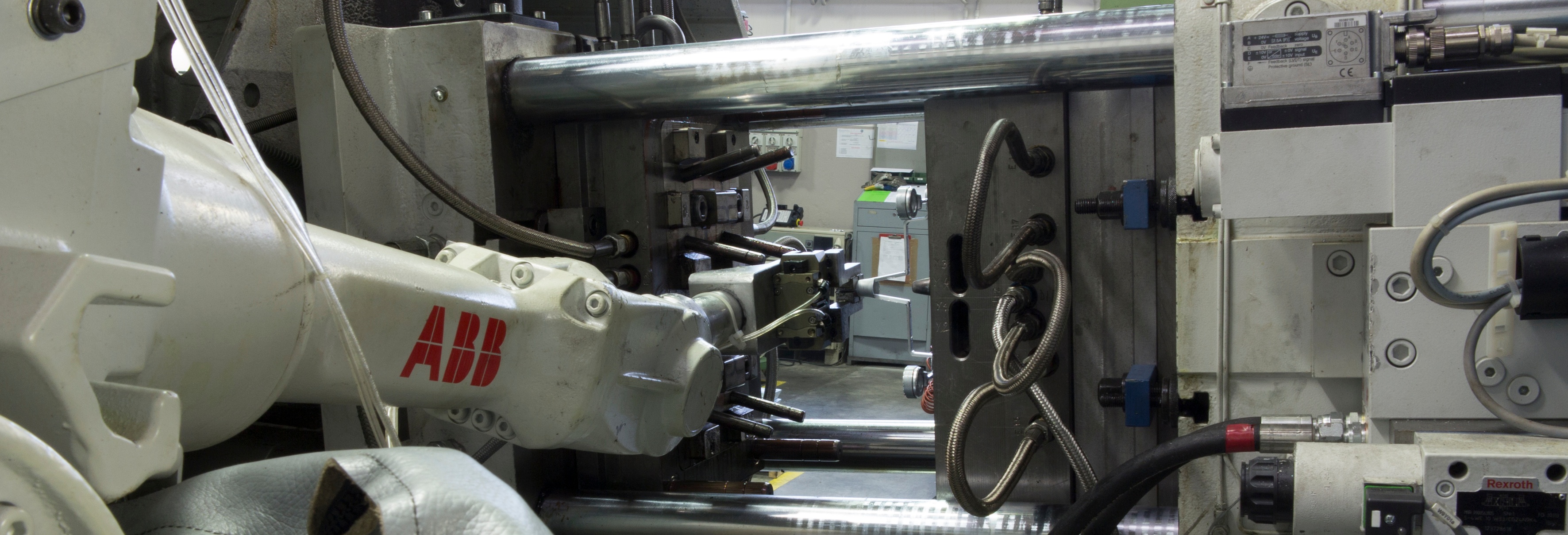

In this post we are going to examine a case study concerning a project for reducing manual operations through the introduction of automation, which has brought benefits to the whole production process.

Process improvement, in the zinc die casting industry as well as in many other manufacturing sectors, consists of a series of actions undertaken to enhance production times, to reduce costs and, consequently, to obtain results that satisfy client’s requests in terms of timing and performance.

In this post we are going to discuss the structure of die casting cycle time and how its optimization can bring various benefits for the company.

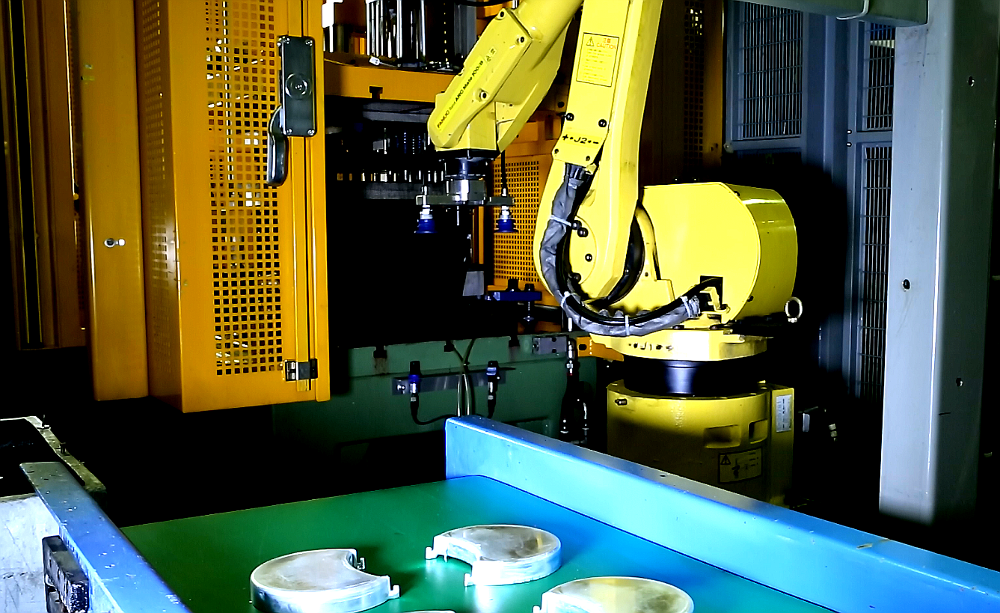

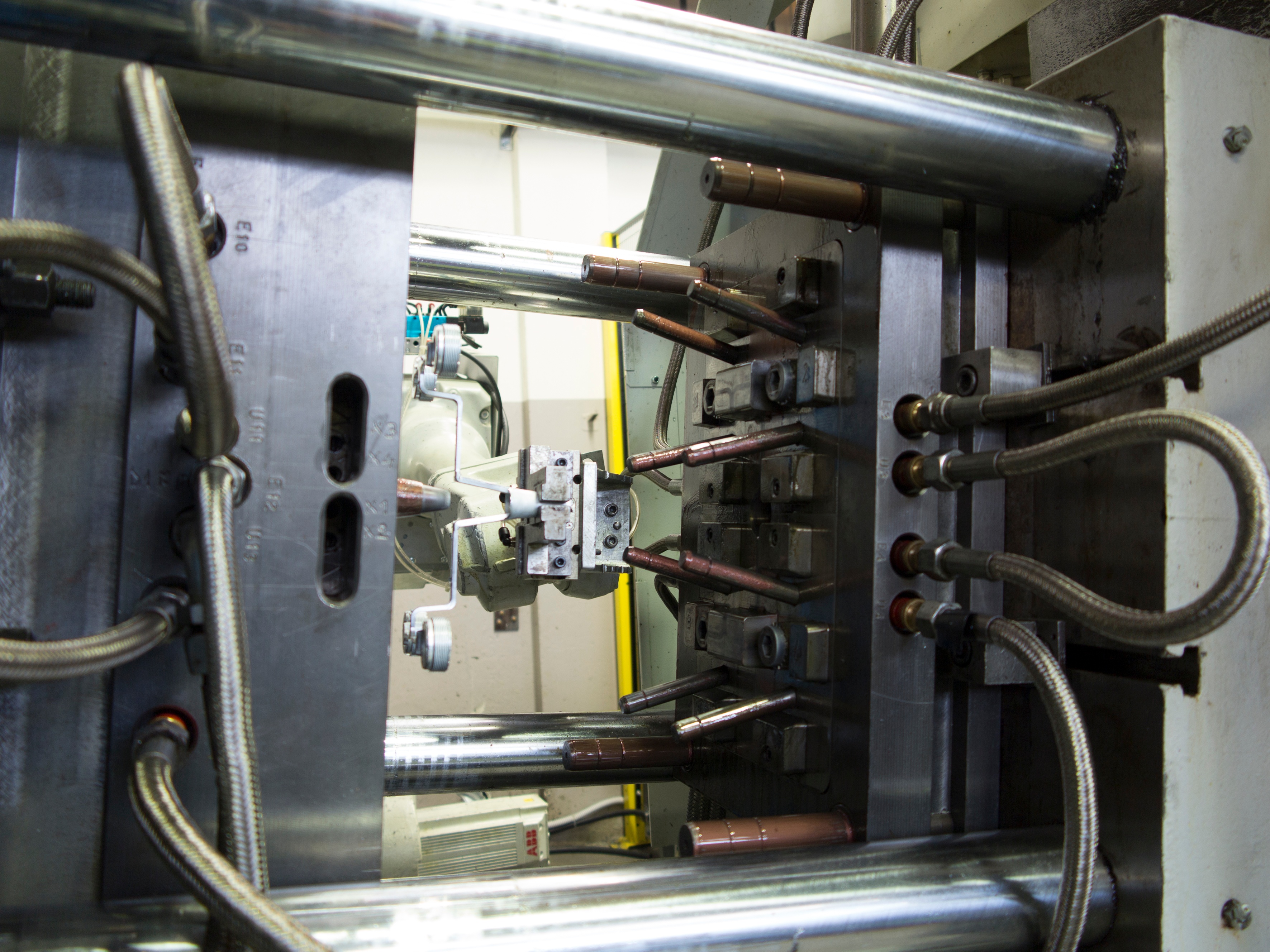

The term automation defines the introduction in a manufacturing company of technical tools and processes aimed at reducing or even eliminating human operations. The incorporation of automatic equipment produces several advantages, such as time saving, costs reduction and better quality outputs, thus achieving customers' satisfaction.