OUR HISTORY

SPECIALIZING IN ZAMAK MOLDING SINCE 1948

1948

FOUNDATION

Giuseppe Bruschi founded his mold-making company to produce zinc alloy components in one of the most challenging periods of Italian history, guided by intuition, skill, and initiative.

1950

GROWTH

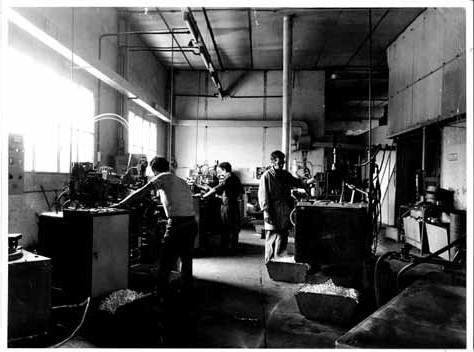

In this phase, as the country recovered from the rubble of the war, the company began to grow and, from a mechanical workshop, evolved into a foundry for creating die-cast objects in zinc alloys. Initially, the company could only count on a semi-automatic machine and a worker, but thanks to prudent entrepreneurial choices, Bruschi gradually strengthened its structure over the years.

1960

CONSOLITATION

The Bruschi name began to stand out in the die-casting market for its ability to find complex design solutions for zinc alloy molding, becoming an important point of reference in the sector.

1980

INNOVATION

The definitive turning point, which led the company to a different market positioning, arrived in 1983: the year of a change at the helm of Bruschi, with the passage of leadership from the founder Giuseppe to his eldest son Marco and the year of the revolutionary vacuum valve in zinc sector. Giuseppe Bruschi revolutionizes the zinc-alloy die-casting industry by applying the vacuum concept, an innovative method in the sector that allows for a global improvement in product performance. This improvement is defined by the increase in the density of the die casting capable of improving its mechanical qualities, which excludes problems related to internal porosity and improves process stability.

2001

SUSTAINED GROWTH

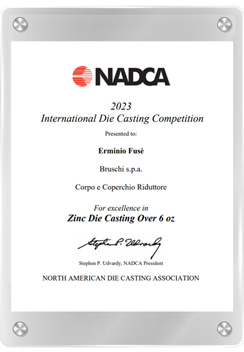

Work and passion have allowed the company to reach high-quality standards, allowing Bruschi to receive prestigious international awards. In 1997 and 2001, Bruschi received the NADCA Award from the North American Die Casting Association. These awards have made Bruschi an internationally recognized leading company in the zinc alloy die-casting sector.

2016

CONTINUITY

The past of Bruschi is made up of projects and products that have resulted in important awards. In September 2016, the company won the third NADCA Award in its history, a competition organized by the North American Die Casting Association, and the prestigious European Zinc Die Casting Competition 2016, organized by the International Zinc Association.

2020

INTERNATIONAL EXPANSION

The change of ownership then gave a significant impetus to the vertical integration project, which allowed Bruschi to position itself on the market as an all-in-one supplier solution in the world of zinc alloy die casting. In 2018, Bruschi structured an internationalization plan, which led to the acquisition of a production plant in the United States in the city of Milwaukee.

2023

DIVERSIFICATION

This geographic market diversification was followed in 2023 by a crucial strategic choice regarding technological diversification. Bruschi has acquired 100% of Sapre Srl, a company specializing in the non-ferrous alloys sector, active in the market since 1988, intending to enter the aluminum alloy die-casting market. Furthermore, Bruschi was awarded the 5th NADCA in its history this year.

Today, Bruschi positions itself as a vertical and integrated technology partner for its customers in Europe and North America, growing from a staff of 220 employees to a post-acquisition team of 270 employees in three different production plants between Italy and the United States.