All the posts for casting-process

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

In this post we analyze proprieties and applications of Zamak components for textile machineries. The textile sector is indeed an interesting sector considering the continuous technological research which makes indispensable the use of high-performance components capable of responding to high technical and production requirements.

In this post, focused on the metrology laboratory, we will describe the devices employed to measure and test zinc alloy die casts intended for different market sectors.

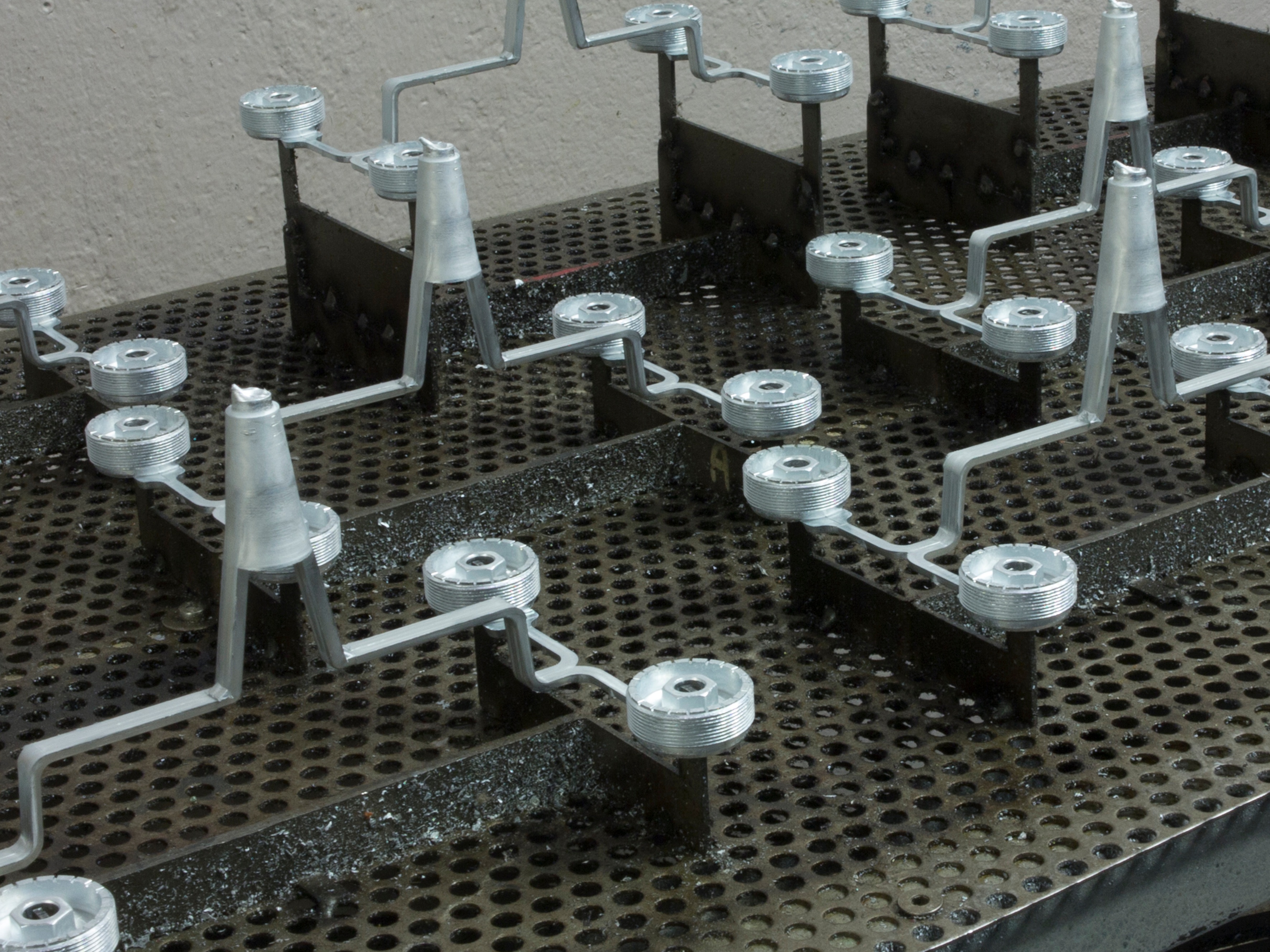

In this post we are going to describe the designing process of a hot chamber injection system, useful for casting process optimization.

In this post we are going to talk about how the use of a HPDC simulation software can benefit the production.

Having a metrology room inside of die casting plant, focused on the dimensional control of the components, assures the requested dimensional quality of production in order to reach customer's needs in terms of lead time and minimize risks.

In the current industrial context, reducing production times will become ever more crucial to offer customers an optimal product in the shortest time possible, with consistent cost savings.

In this article we are going to analyze a particular corrosion test called Salt Spray Test - SST, normally used to test coatings for automotive parts, in order to test their salt or mist resistance.

Zinc die casting process can have important advantages compared to other manufacturing process: for example can lead to major cost savings during production cycle, allows to create complex product shapes and is possible to eliminate unnecessary assembly operations combining multiple components into a single one.

Nowadays using technology software such as die casting simulation allows optimizing the whole production cycle. Today’s ever-changing international marketplace is highly demanding and challenging: using the newest tools from supplier side mean giving clients innovative solutions to reach their expectations. The following article will explain how to obtain consistent savings with die casting simulation.

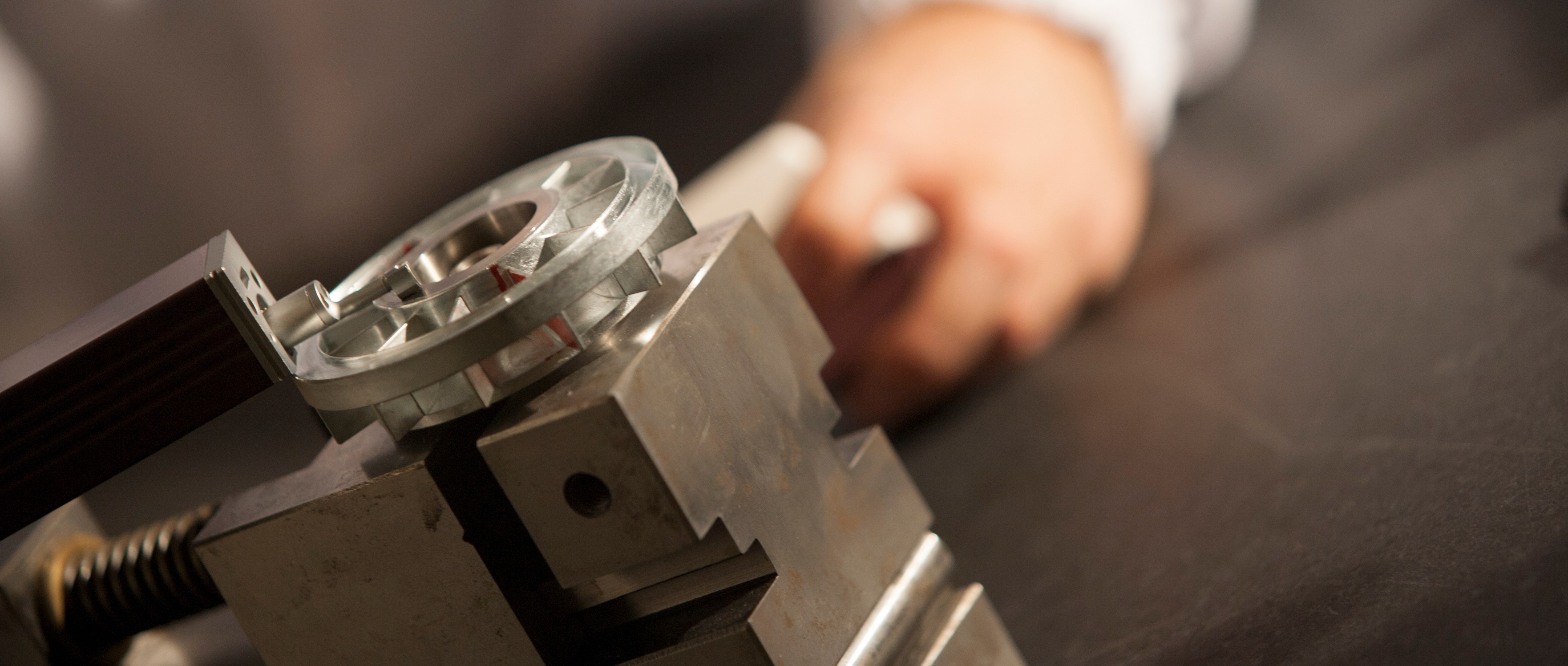

In order to apply a cost reduction in casting the designer should have a global view of the entire process. Casting process is composed of different phases that allow zamak becoming finished and packaged product: in this post we will examine the six stages of die casting process and analyze how and when it is possible to reduce costs.