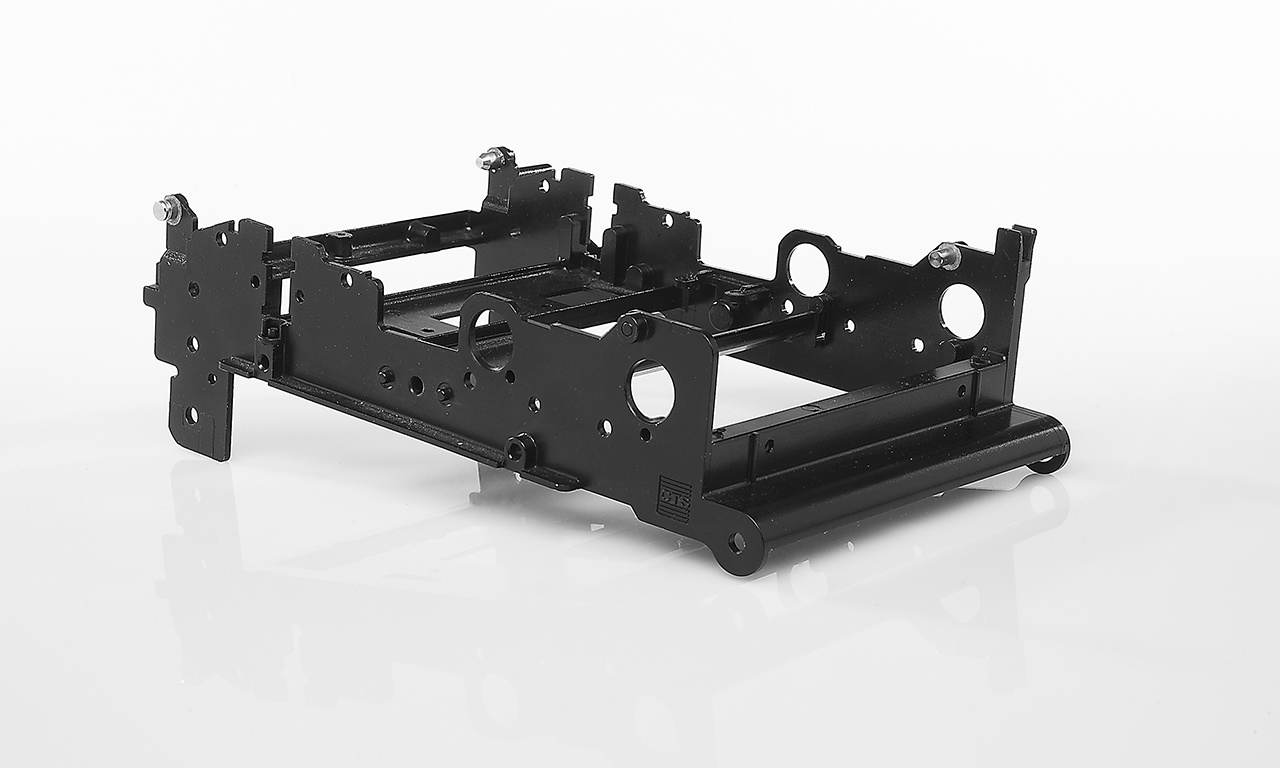

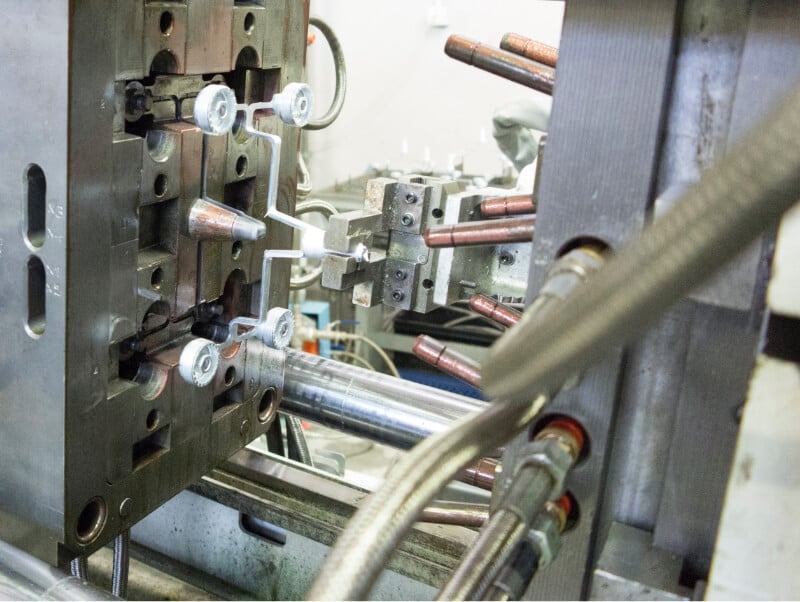

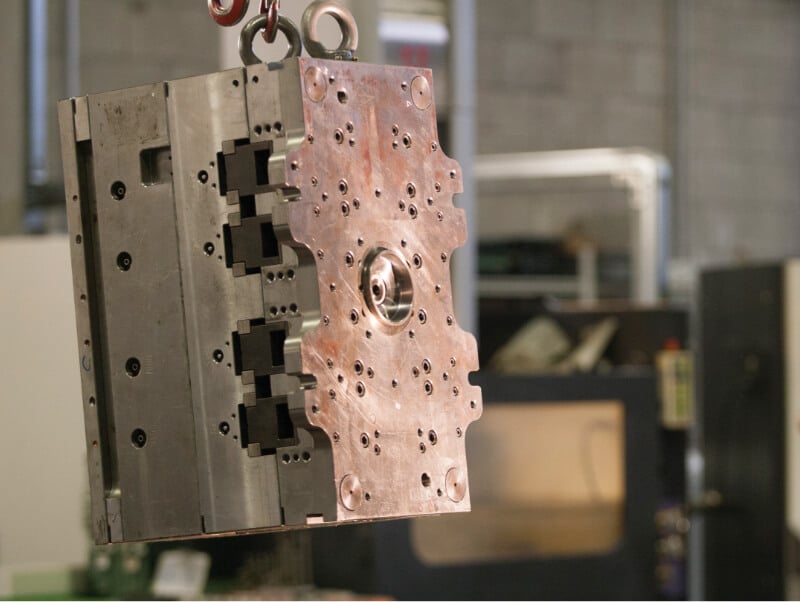

Zinc die casting

We are an all in one solution supplier: Experts in zinc die casting since 1948

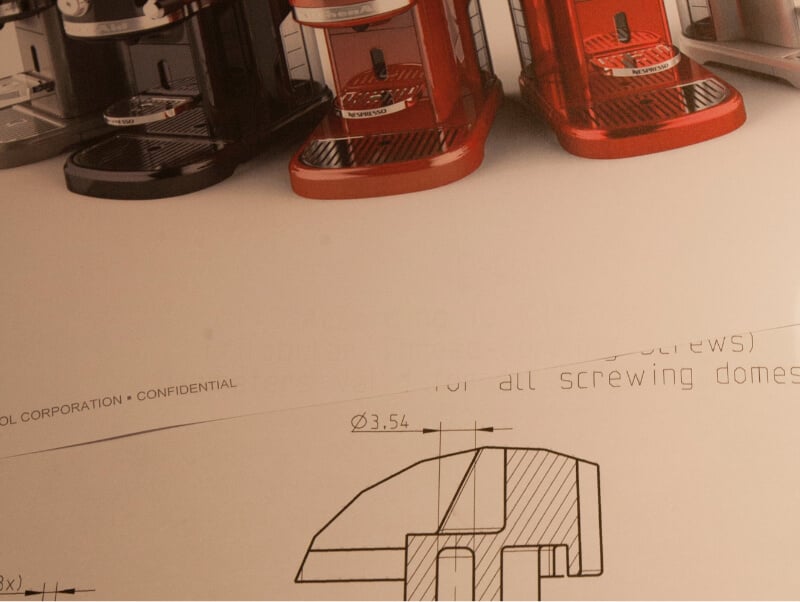

Zinc die casting design requires precision and technical skill. In Bruschi you will find this conjunction with the best services to develop the best components for your products. A deep knowledge and a lot of experience is essential components to obtain high-level results using the best zinc die casting technologies. Discover our services and applications