All the posts for saving

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

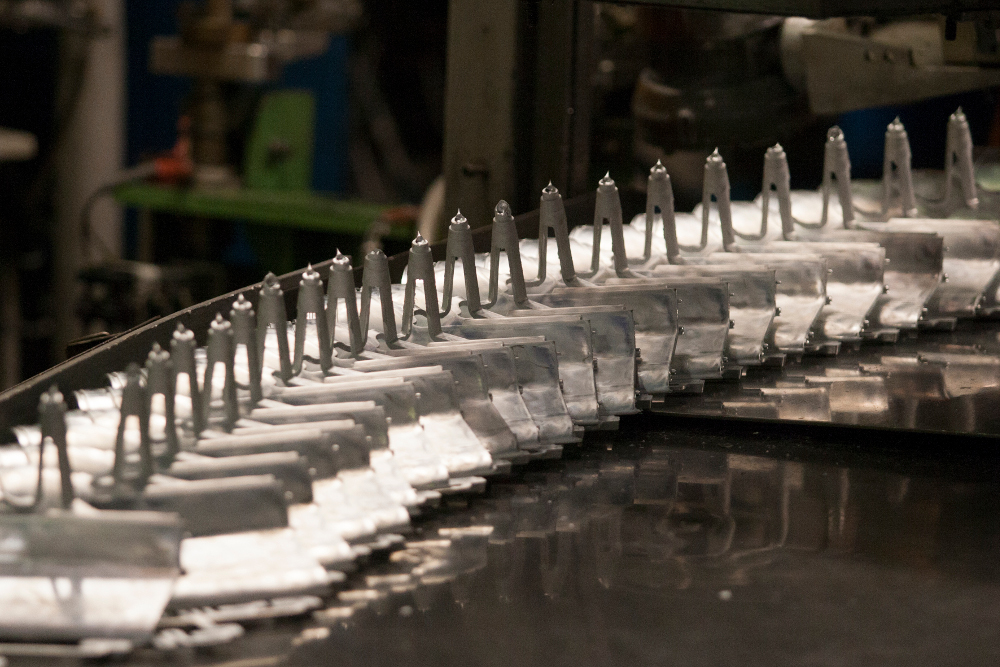

Cost reduction in zinc die casting is an activity that shall be executed without affecting the quality and functionality of the component that is produced. All the activities that aim to increase productivity, to diminish scrap rate and to simplify productive processes, as well as the choices of materials and processing, are cost reduction strategies.

Zinc die casting process can have important advantages compared to other manufacturing process: for example can lead to major cost savings during production cycle, allows to create complex product shapes and is possible to eliminate unnecessary assembly operations combining multiple components into a single one.

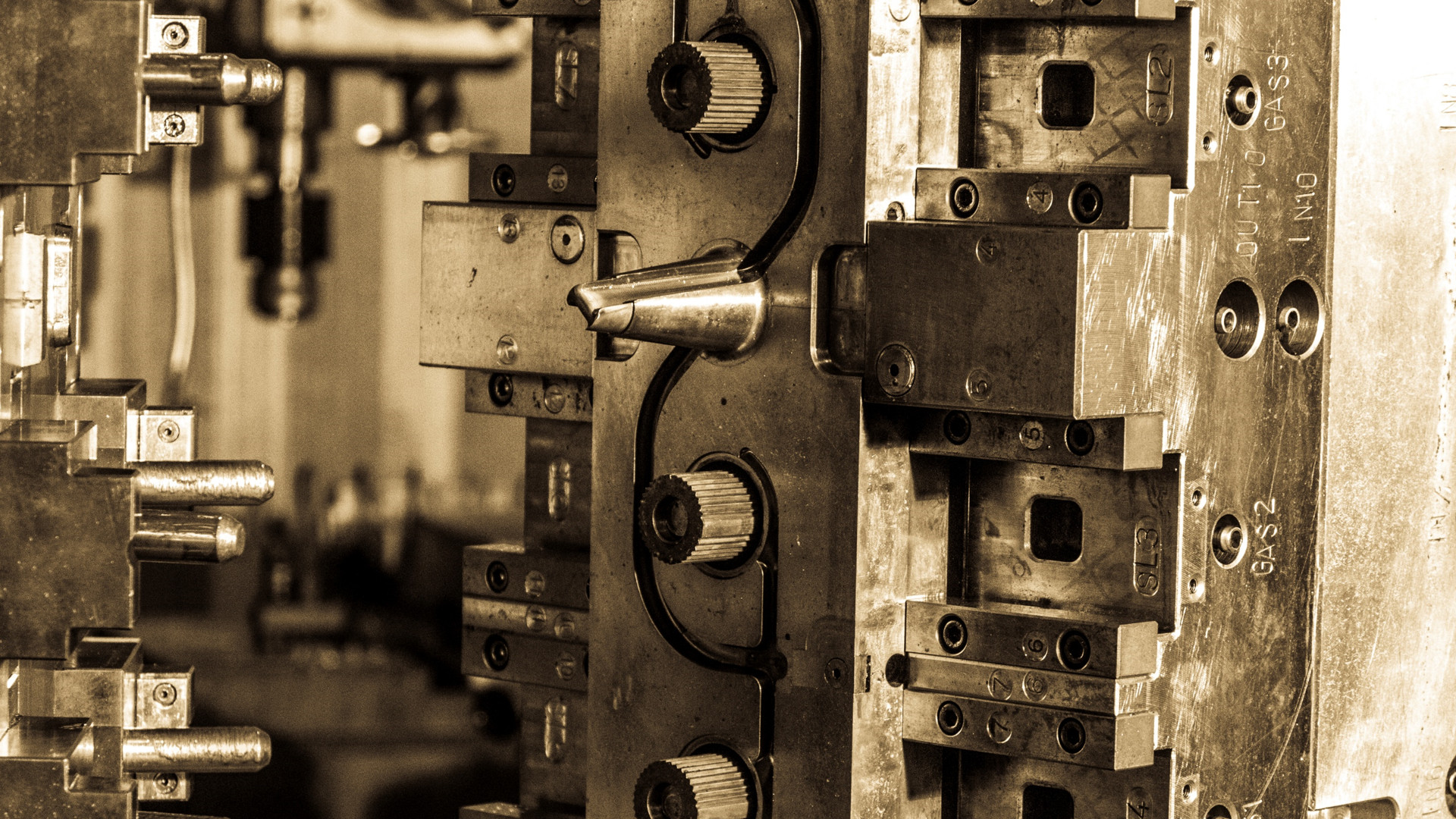

Die casting companies that use simulation tools can give important benefits to its customers. Using these simulation tools can allow to obtain an important saving in terms of money and time in different ways. In this article we are going to analyze benefits of simulation during the development of a new component or product.

The most important element selecting the materials for the production and processes is trying to minimize costs of the product and its production. Producing, finishing, delivering and assembling costs depend on a wide range of factors. In this post we are going to understand in which areas companies can obtain costs savings.

Supply chain is the management of the flow of goods and services from the point of origin to the point of consumption: a cluster of activities done in order to meet customer’s requirements, to coordinate the suppliers, clients and the company itself. In this post we are going to describe how a well-structured supply chain can lead to costs saving.