All the posts for optimization

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

Cost reduction in zinc die casting is an activity that shall be executed without affecting the quality and functionality of the component that is produced. All the activities that aim to increase productivity, to diminish scrap rate and to simplify productive processes, as well as the choices of materials and processing, are cost reduction strategies.

Process improvement, in the zinc die casting industry as well as in many other manufacturing sectors, consists of a series of actions undertaken to enhance production times, to reduce costs and, consequently, to obtain results that satisfy client’s requests in terms of timing and performance.

In this post we are going to explore two case study: the first one is dedicated to resolving issues with die maintenance for a component of automotive sector, while the second one regards the optimization of set up parameters for a component of small domestic appliances.

In this post we are going to describe what is meant with surface finishing and we will explain why it is important to take them in consideration from the designing phase of a component, giving some advice for the optimization of the most critical points.

In this post we are going to explain what Value Analysis / Value Engineering is, starting from its history up to why it is so important for manufacturers today.

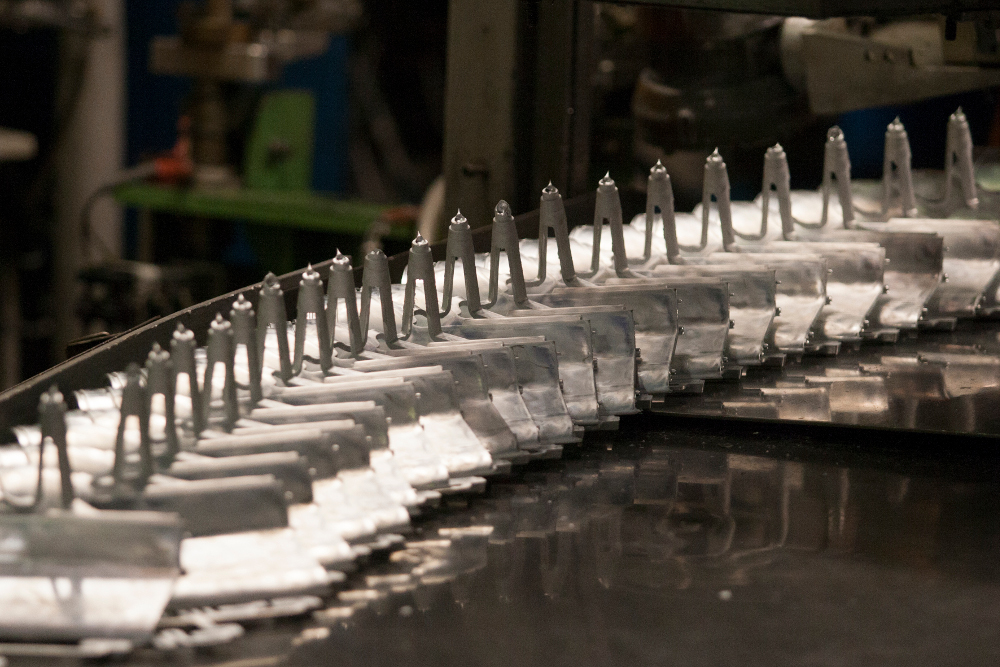

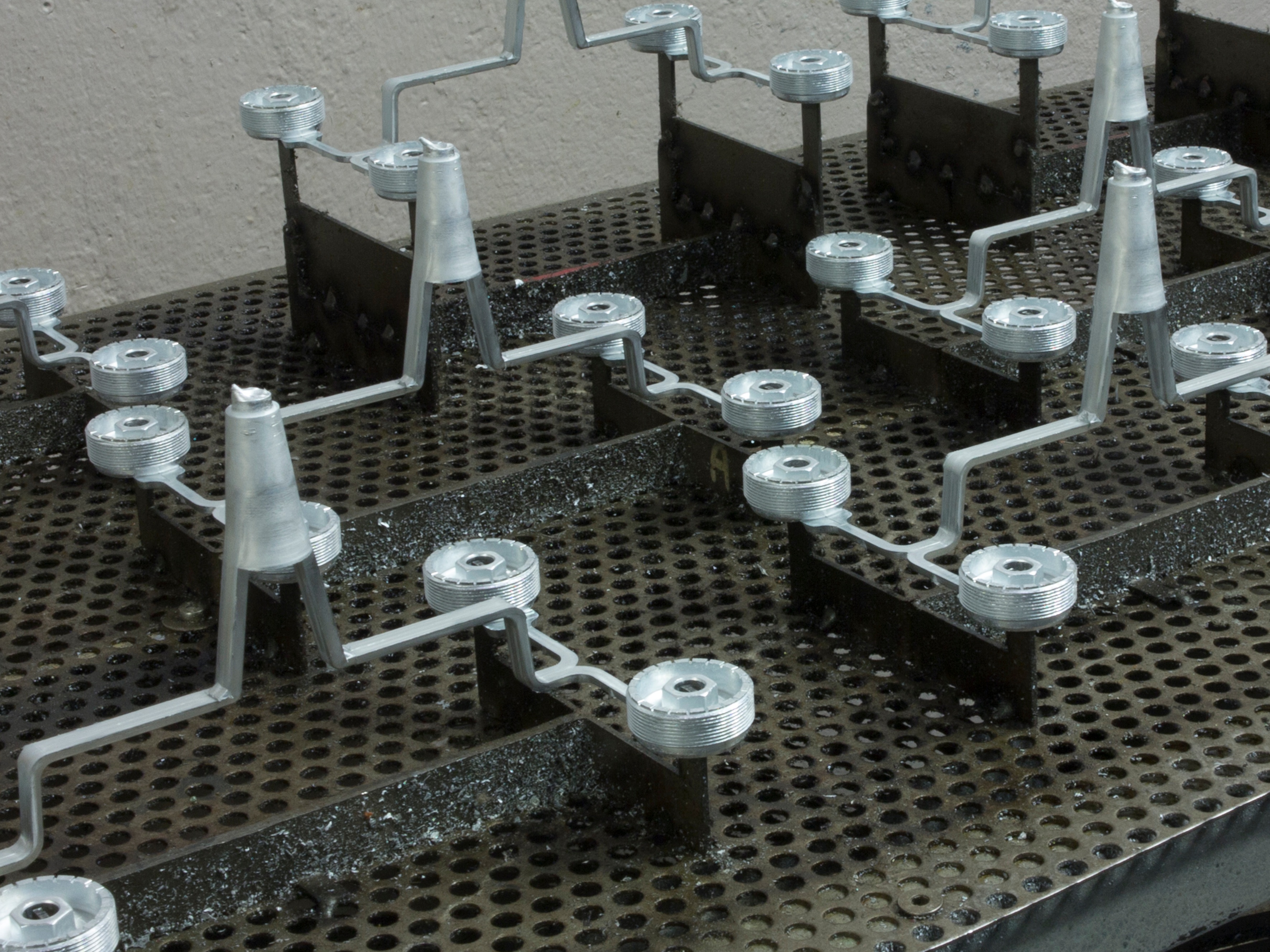

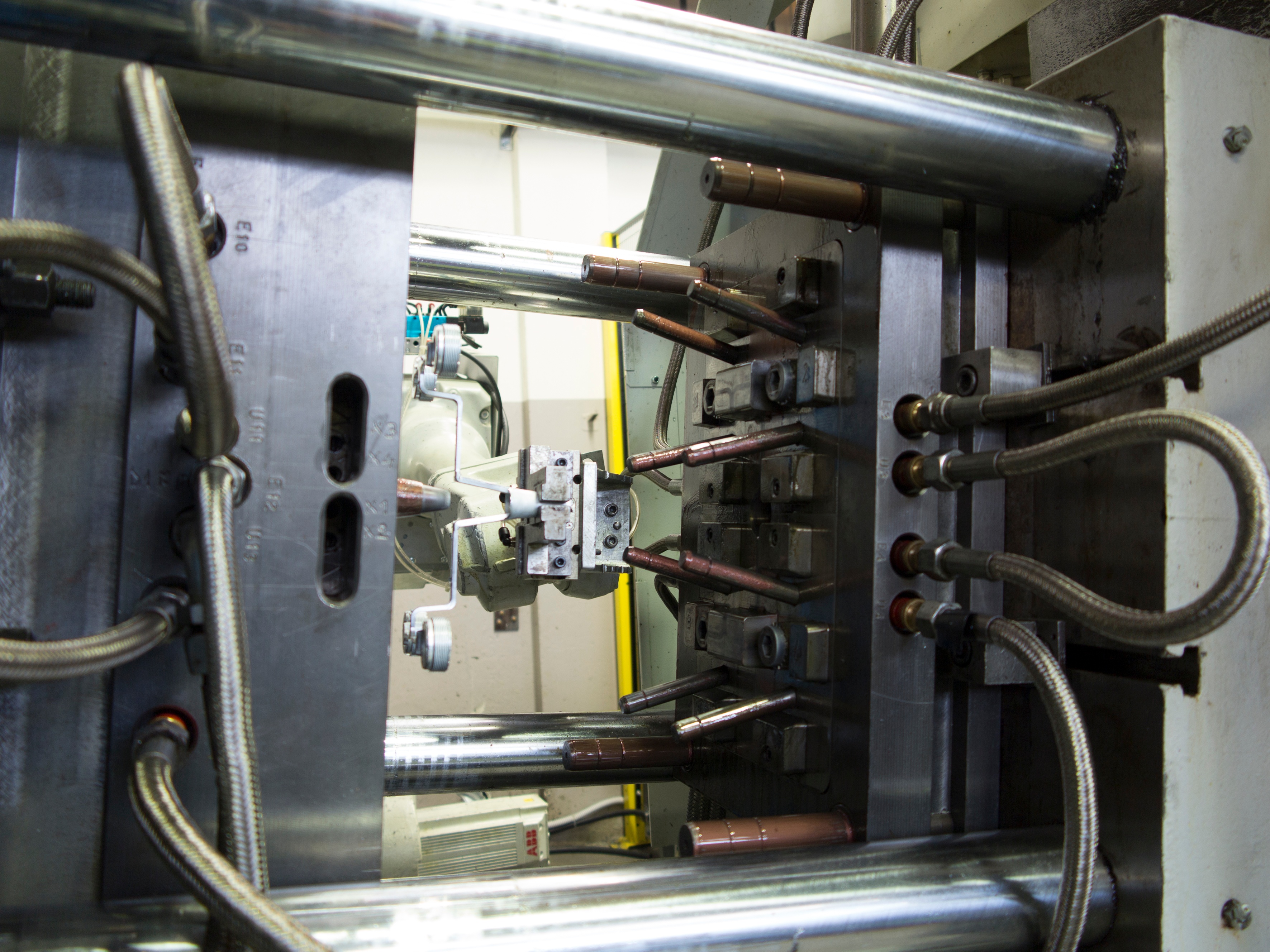

In this post we are going to describe the designing process of a hot chamber injection system, useful for casting process optimization.

In this post we are going to discuss the structure of die casting cycle time and how its optimization can bring various benefits for the company.

In this post we are going to talk about how the use of a HPDC simulation software can benefit the production.

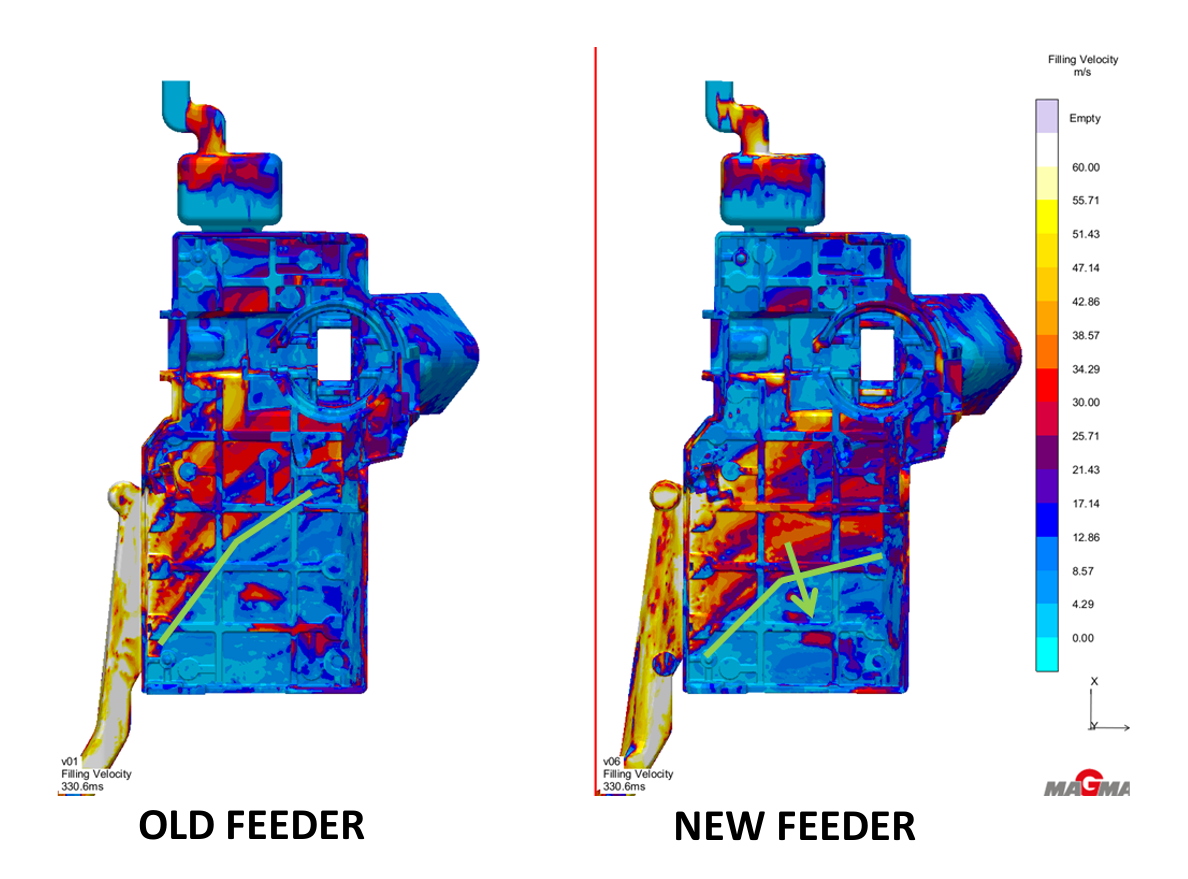

Nowadays using technology software such as die casting simulation allows optimizing the whole production cycle. Today’s ever-changing international marketplace is highly demanding and challenging: using the newest tools from supplier side mean giving clients innovative solutions to reach their expectations. The following article will explain how to obtain consistent savings with die casting simulation.

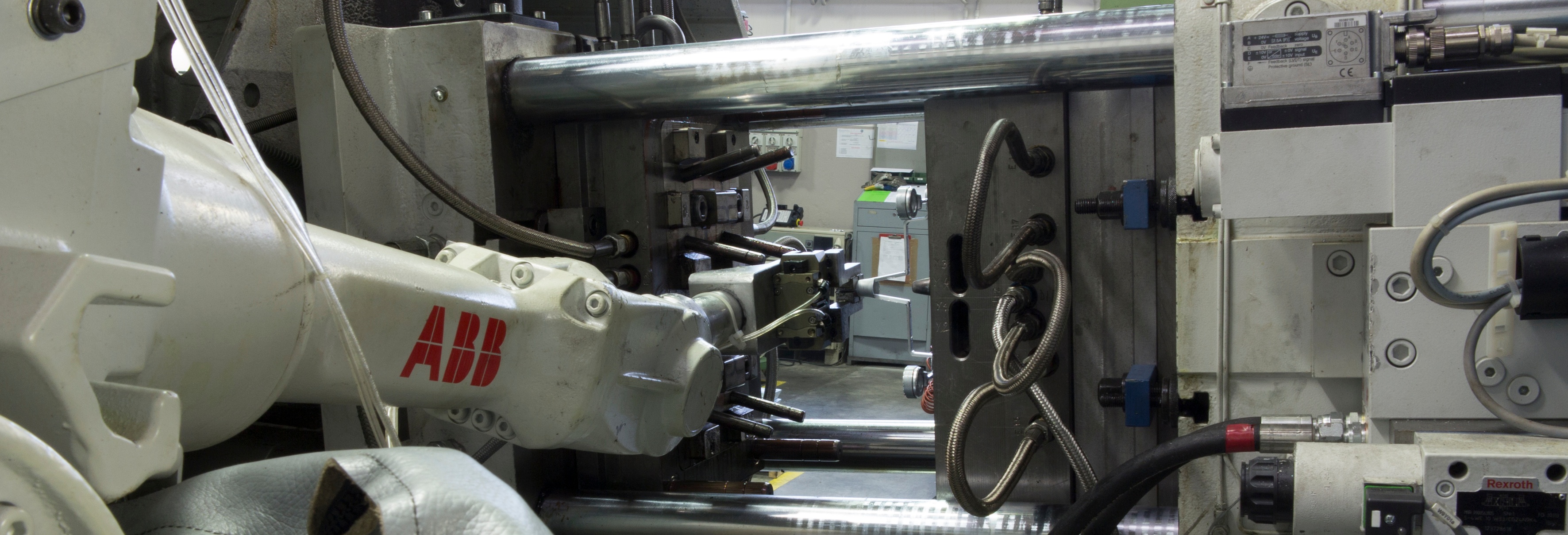

The term automation defines the introduction in a manufacturing company of technical tools and processes aimed at reducing or even eliminating human operations. The incorporation of automatic equipment produces several advantages, such as time saving, costs reduction and better quality outputs, thus achieving customers' satisfaction.