Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

In this post we are going to discuss the advantages of involving suppliers in procurement strategy, and how they can impact the final result of a VA/VE analysis.

In this post we are going to explain what Value Analysis / Value Engineering is, starting from its history up to why it is so important for manufacturers today.

In this post we are going to analyze some surface defects in die casting linked to errors in the painting process of zinc die cast products.

In this post we are going to list the most common defects in zinc die casting surface treatments and explain how to prevent them. We are going to analyze the following defects: blisters, pitting, burnings, nodules and flaking.

ZAMAK molding is the creation of components using zinc alloys for die casting. In this post we are going to discuss how the choice of the alloy can affect the final result of hot chamber die casting.

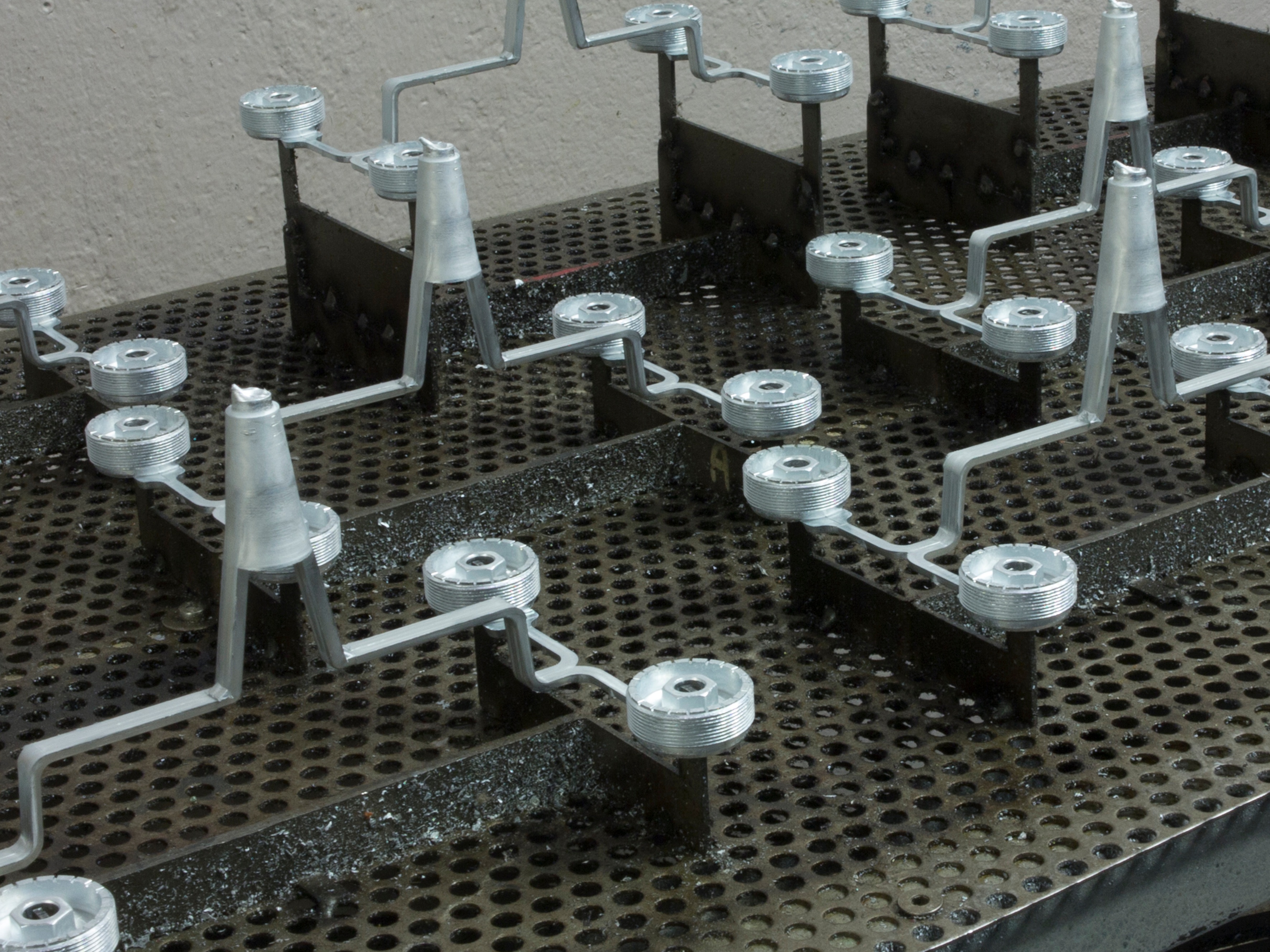

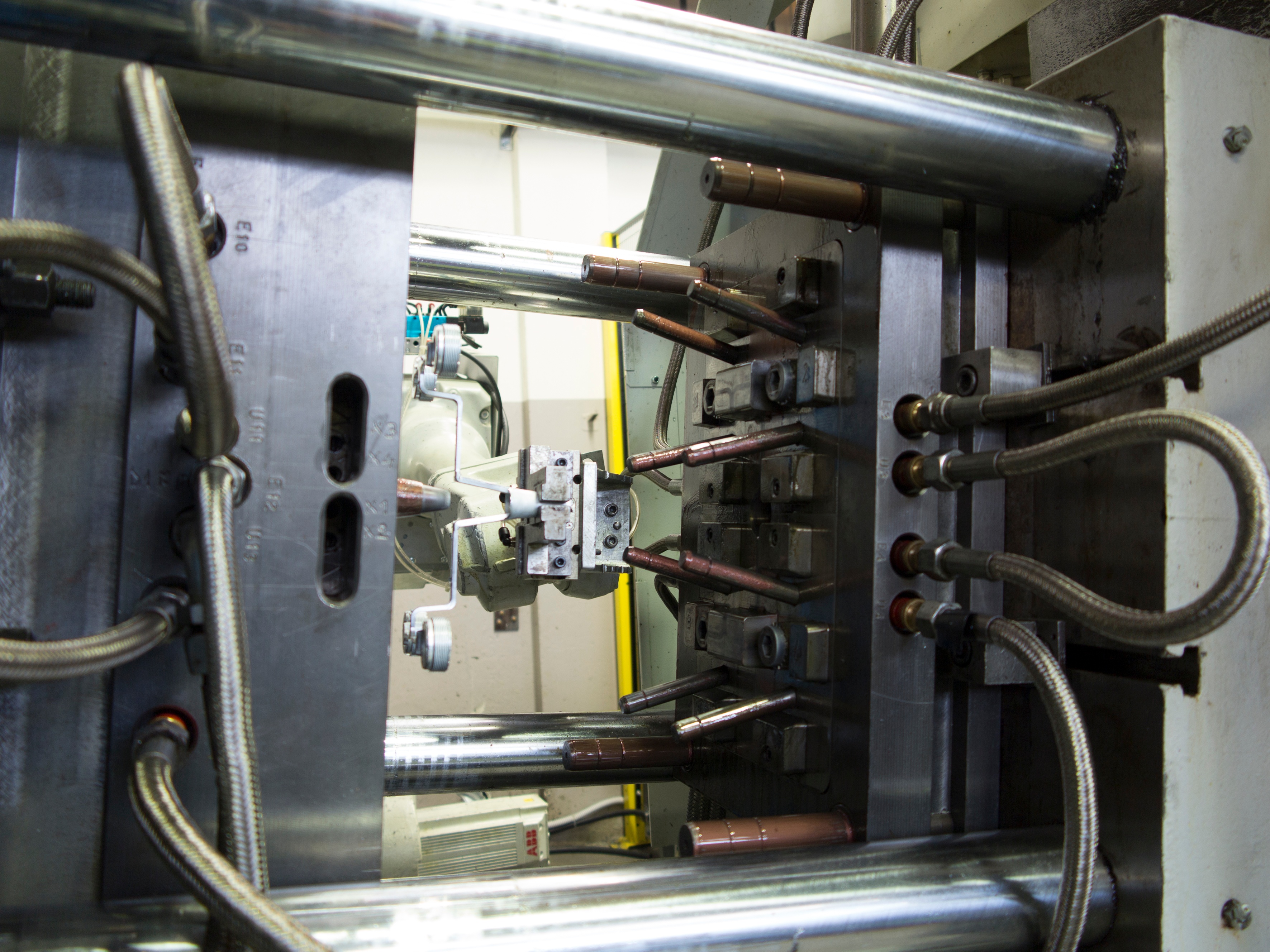

In this post we are going to describe the designing process of a hot chamber injection system, useful for casting process optimization.

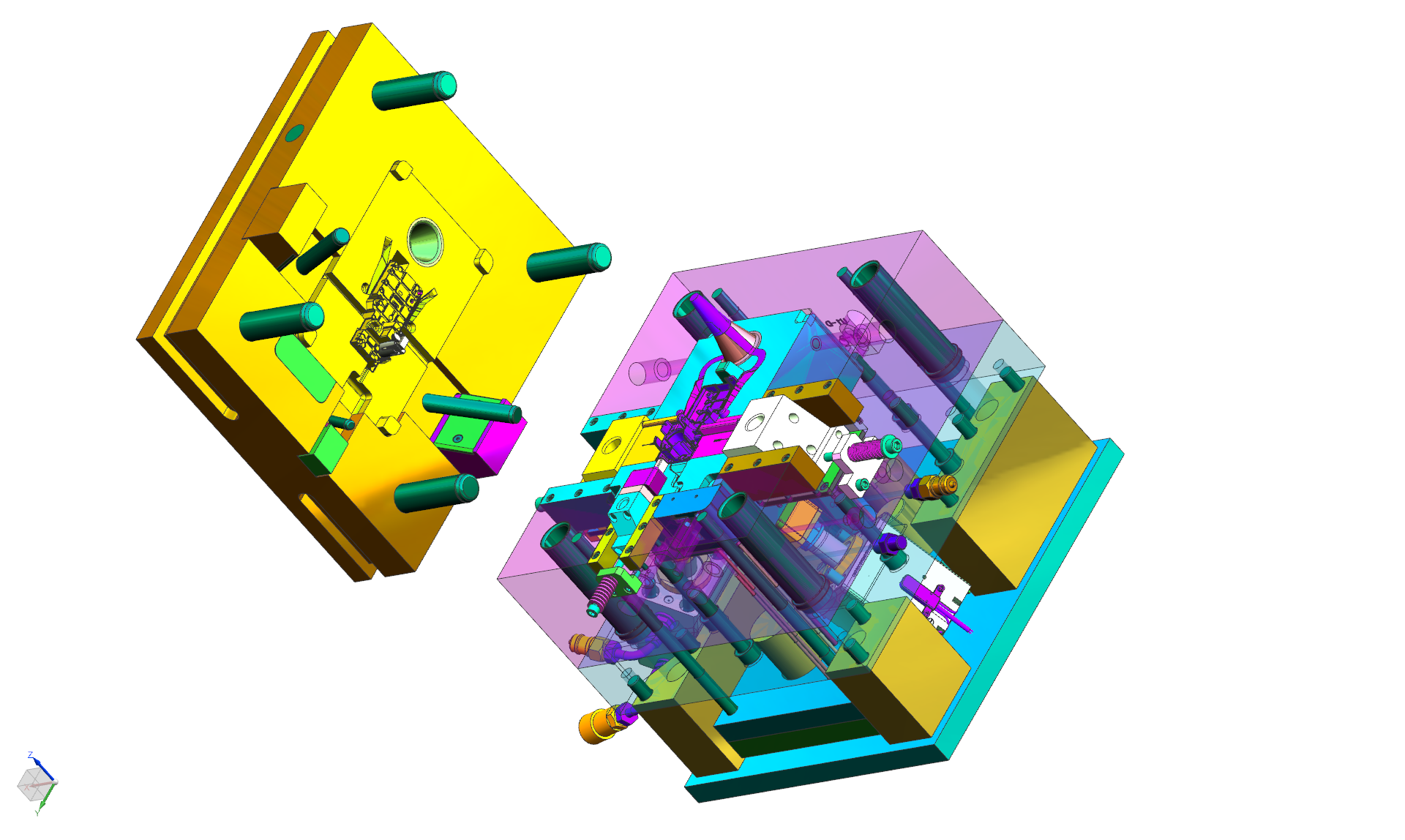

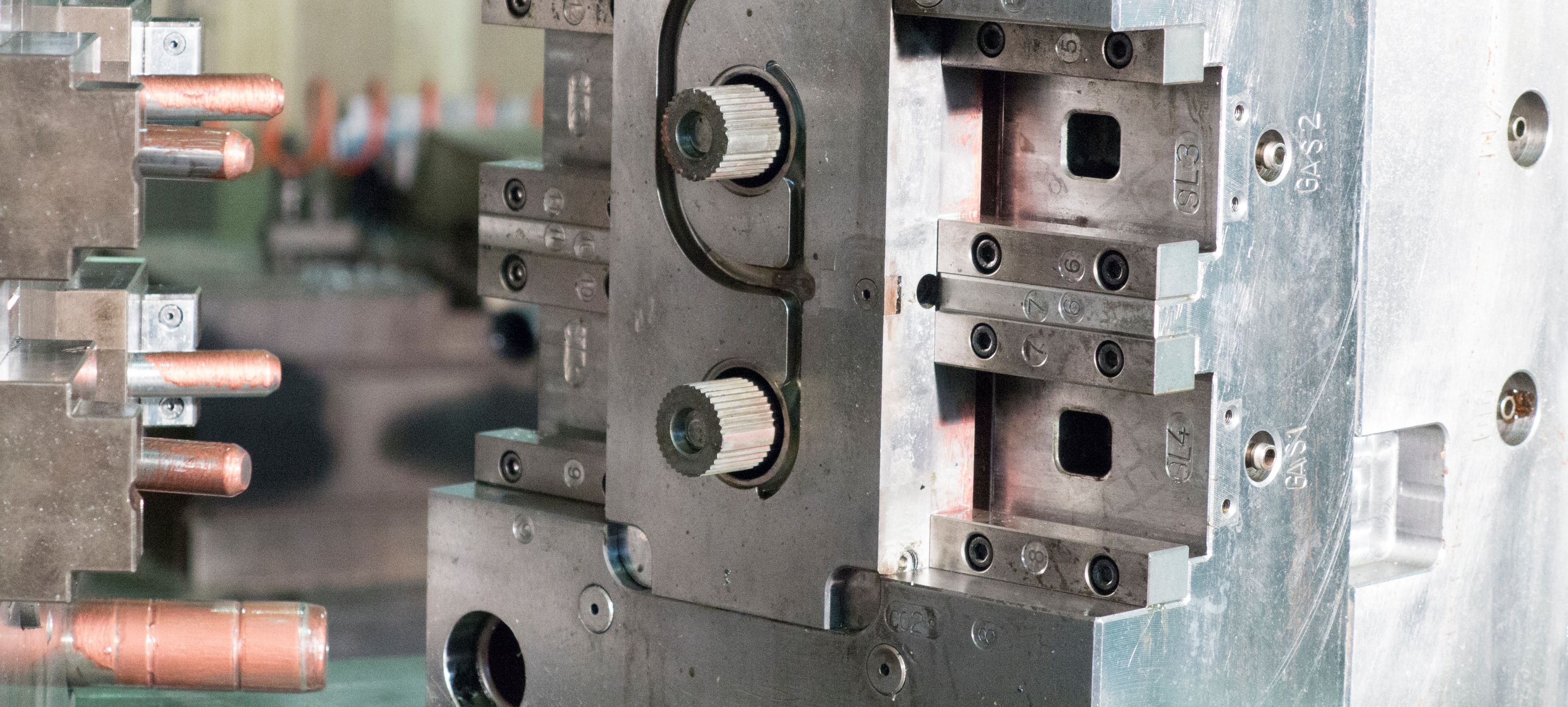

In this post we are going to fully describe the process of mold design for high pressure die casting.

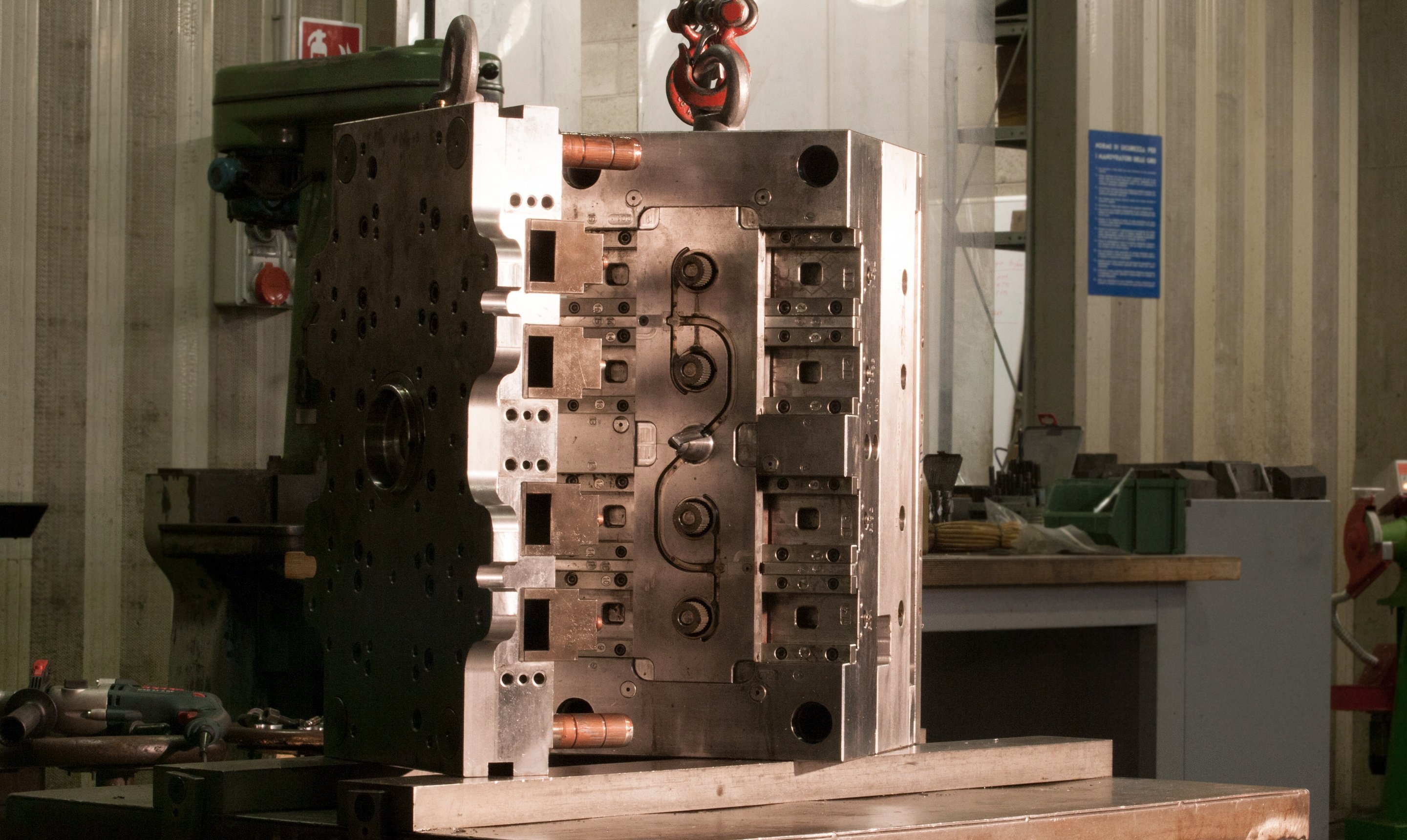

In this post we are going to discuss some of the most common defects in die casting linked to mold maintenance, and how they can be fixed by the maintenance department.

In this post we are going to discuss the structure of die casting cycle time and how its optimization can bring various benefits for the company.

In this post we are going to describe in detail the relation between mold maintenance department and foundry: how the inclusion of maintenance department and tooling department in the production area can bring actual economic advantages and time saving.