Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

Process improvement, in the zinc die casting industry as well as in many other manufacturing sectors, consists of a series of actions undertaken to enhance production times, to reduce costs and, consequently, to obtain results that satisfy client’s requests in terms of timing and performance.

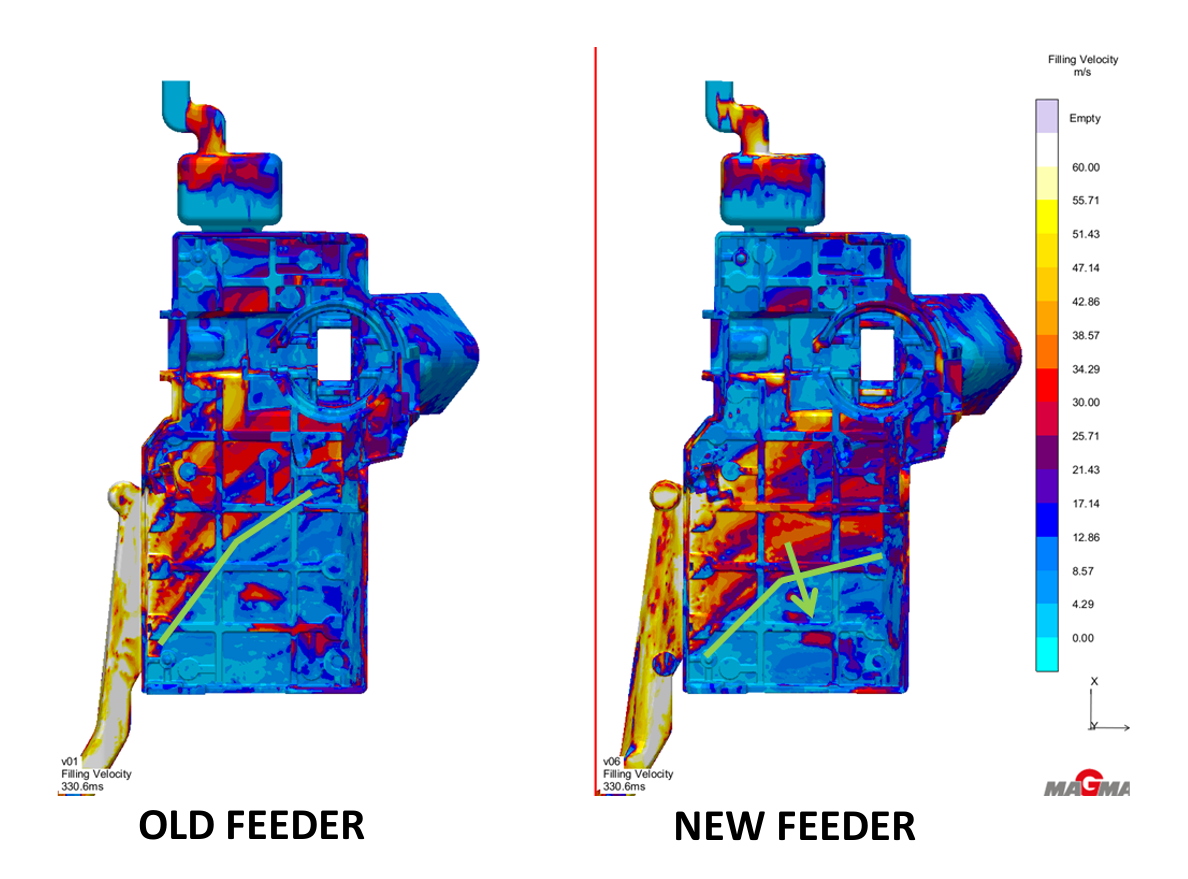

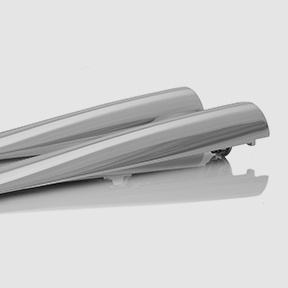

In this post we are going to explore a case study dedicated to surface aesthetical quality in automotive. This post is part of a series in which we explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of real life cases.

In this post we are going to describe the business philosophy of functional beauty. Starting from this philosophy, Bruschi created Nespresso KitchenAid Artisan 5KES0503, a design coffee machine that led the company to the victory of the prestigious European Zinc Die Casting Competition for design in 2016.

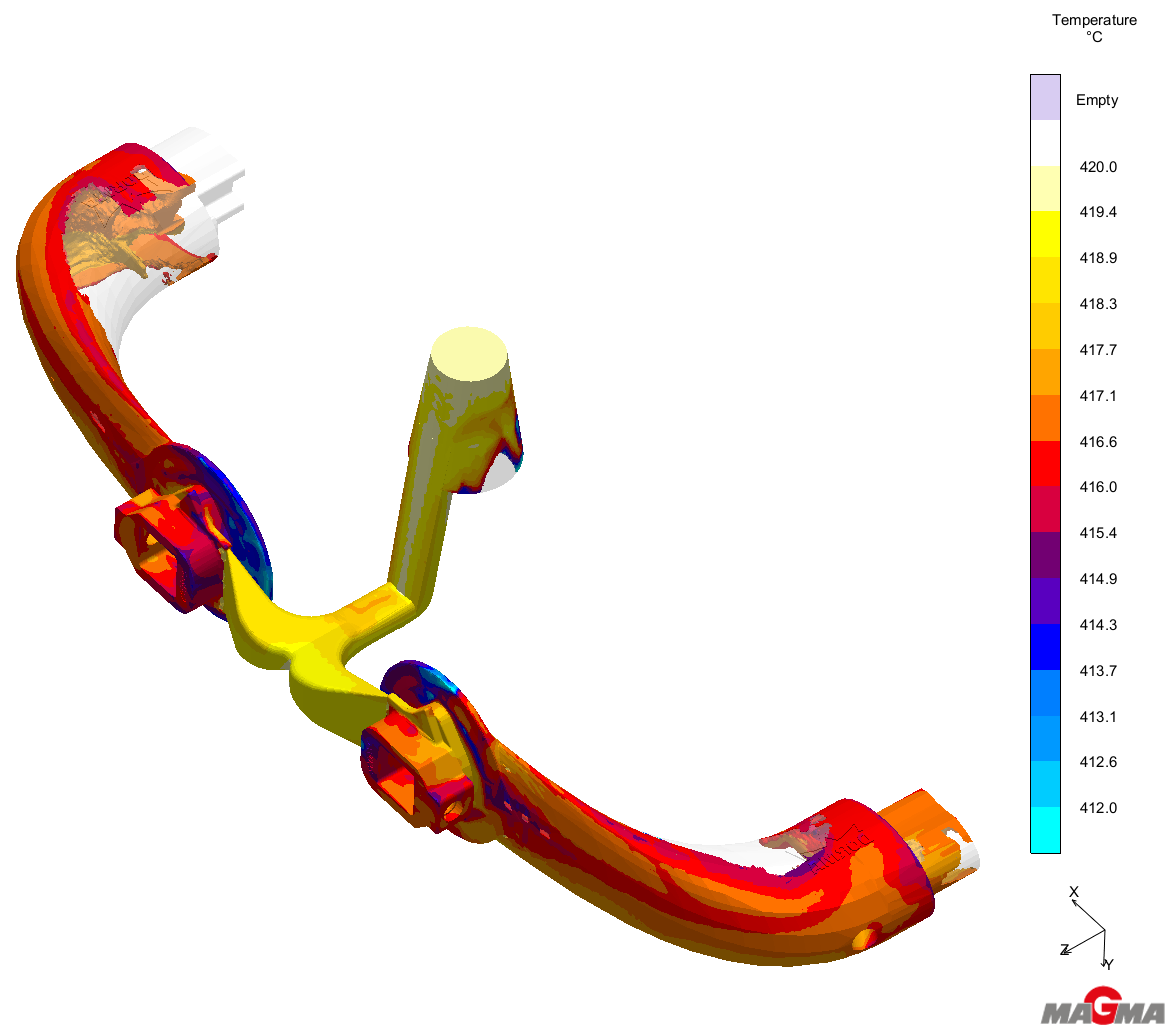

In this post we are going to explore two case study: the first one is dedicated to resolving issues with die maintenance for a component of automotive sector, while the second one regards the optimization of set up parameters for a component of small domestic appliances.

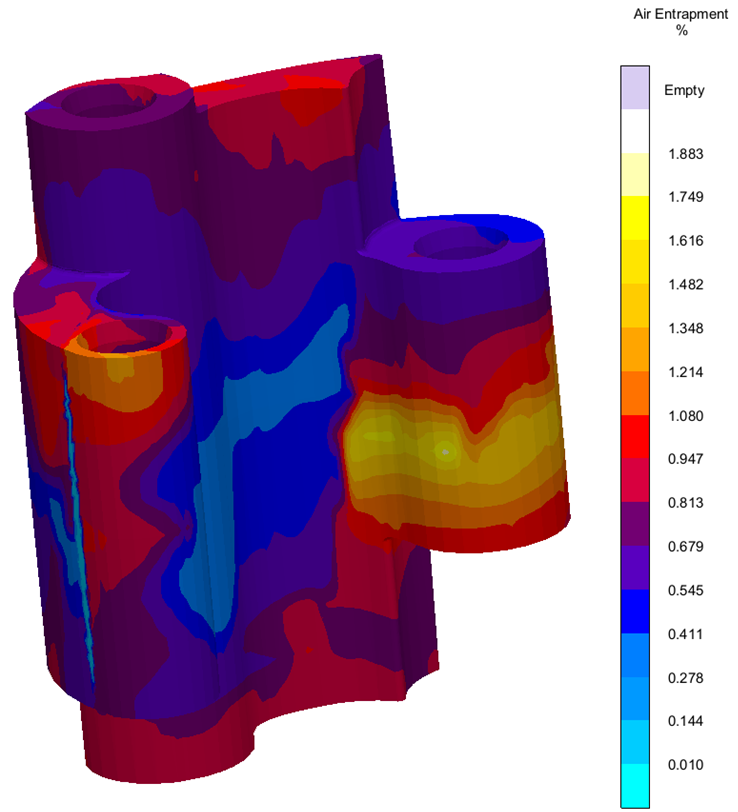

In this post we are going to explore a case study dedicated to the improvement of mechanical characteristics, by reducing shrinkage porosity in a component for building sector. This post is part of a series in which we explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of real life cases.

The process of zinc die casting is highly popular for making parts in building and industrial fields, but its most common application is in automotive industry. In fact, cars have different parts that can be crafted through die casting, so much that the modern process of die casting originally started for automotive industry.

In this series of posts, we are going to explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of different case studies, in which simulation played a crucial role.

In this post we are going to list and define the most common surface treatments for zinc die casting and their effects, and we are going to present three case studies in which the application of a specific treatment helped in improving the overall performance of the component.

In this post we are going to list some of the most common processing techniques for metal finishing and their effect on the surfaces.

In this post we are going to describe what is meant with surface finishing and we will explain why it is important to take them in consideration from the designing phase of a component, giving some advice for the optimization of the most critical points.