Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

A vertical approach to production starts from product co-design and mold design, followed by tool manufacturing and the definition of the die casting process.

The production cycle is eventually completed by additional treatments or processes, which allows the die caster to offer not only die cast parts, but also finished goods. This can also happen through to the cooperation with external, specialized partners.

More specifically, this post will deal with chrome plating and painting of zinc die castings.

This post deals with the fundamentals of die casting machines and their role in the whole die casting process. Moreover, the post gives an outlook on the sector's future perspectives.

In this post we will focus on zinc alloy actuators of large air conditioning systems, explaining what they are and how their components work.

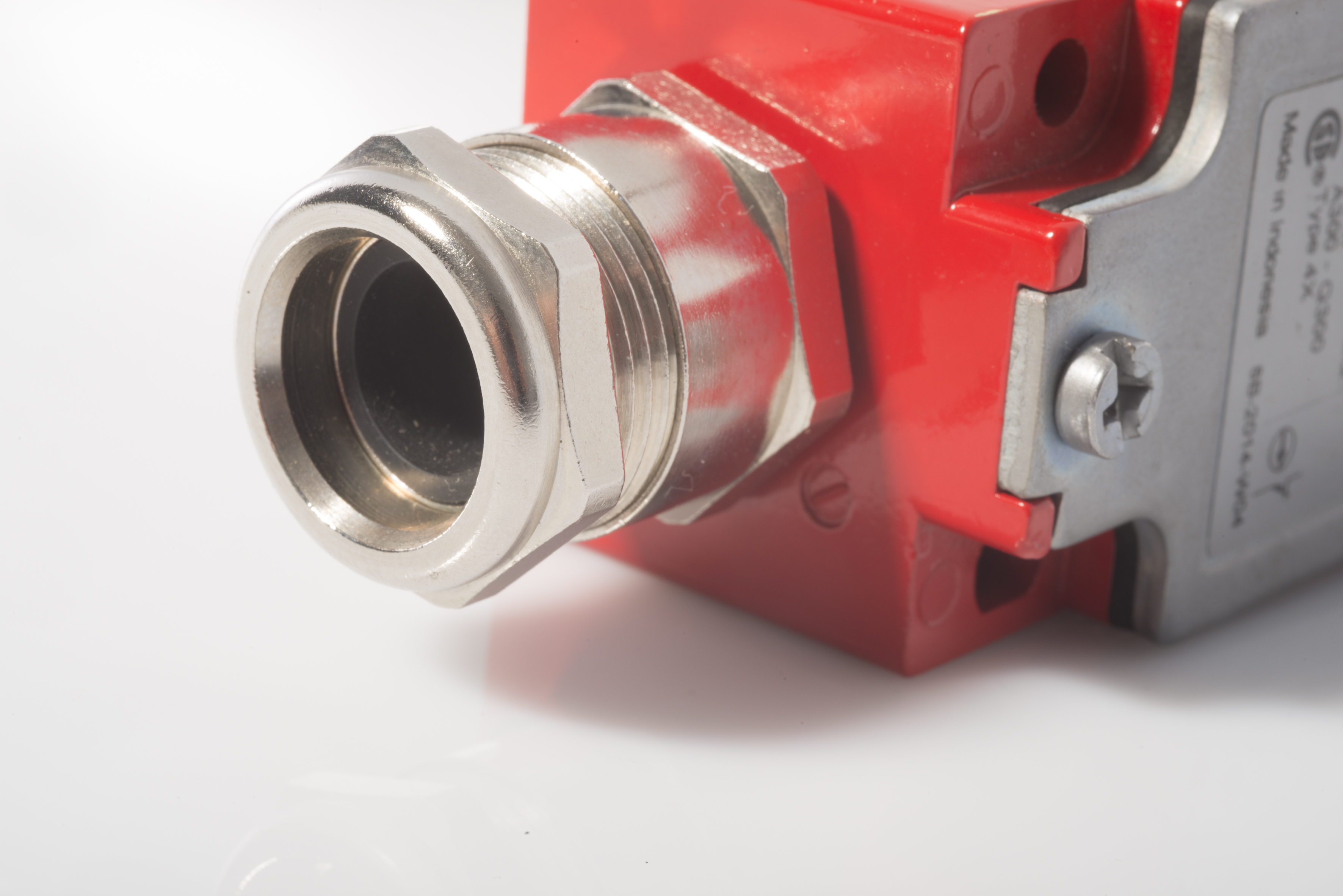

In this post we will analyze the properties of zinc components for electromechanical systems and then review some products that can illustrate the advantages that Zamak can confer to articles intended for this sector.

In this post we analyze proprieties and applications of Zamak components for textile machineries. The textile sector is indeed an interesting sector considering the continuous technological research which makes indispensable the use of high-performance components capable of responding to high technical and production requirements.

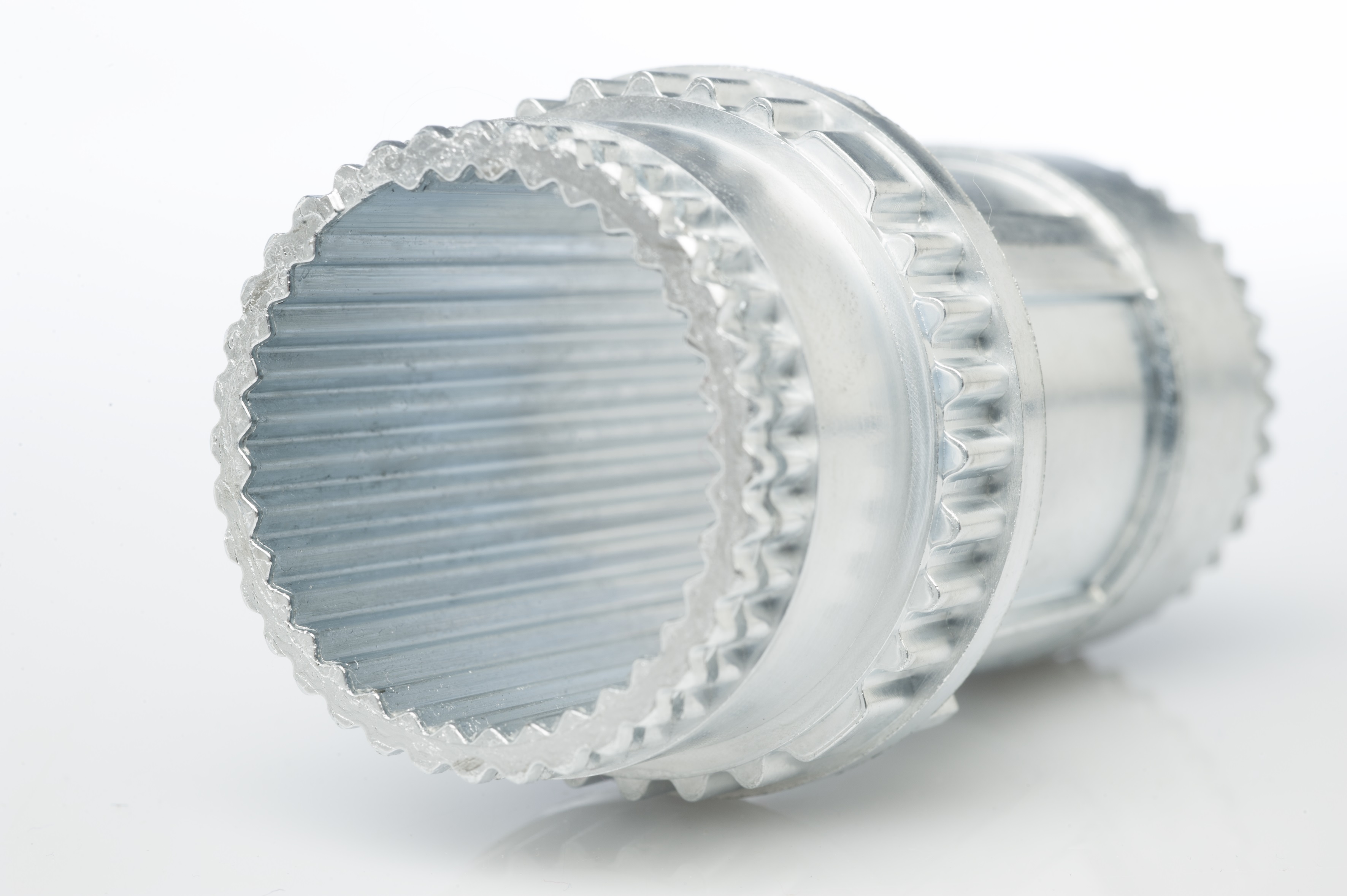

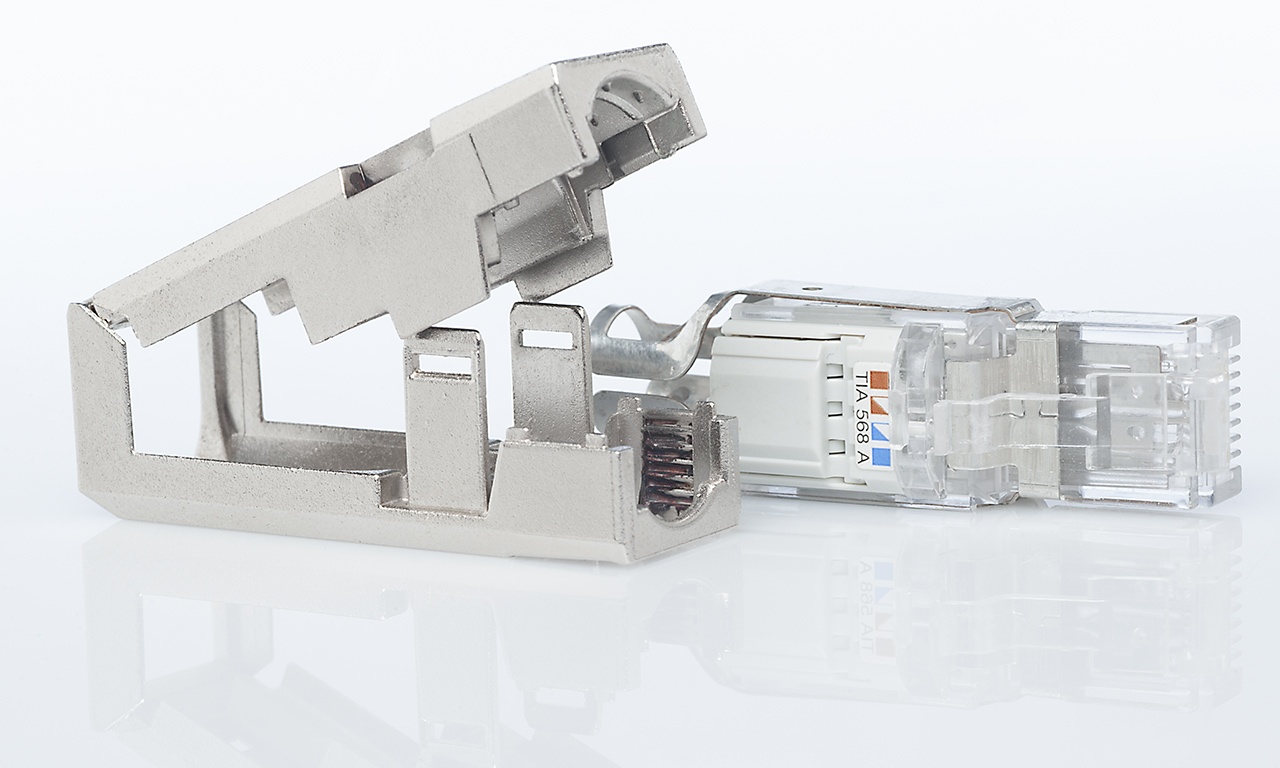

In this post we are going to briefly analyze the characteristics of zamak and to highlight its advantages in the production of components for electronic products. After that, we will review some components explaining how choosing zamak has made them more beneficial compared with similar products manufactured with other materials.

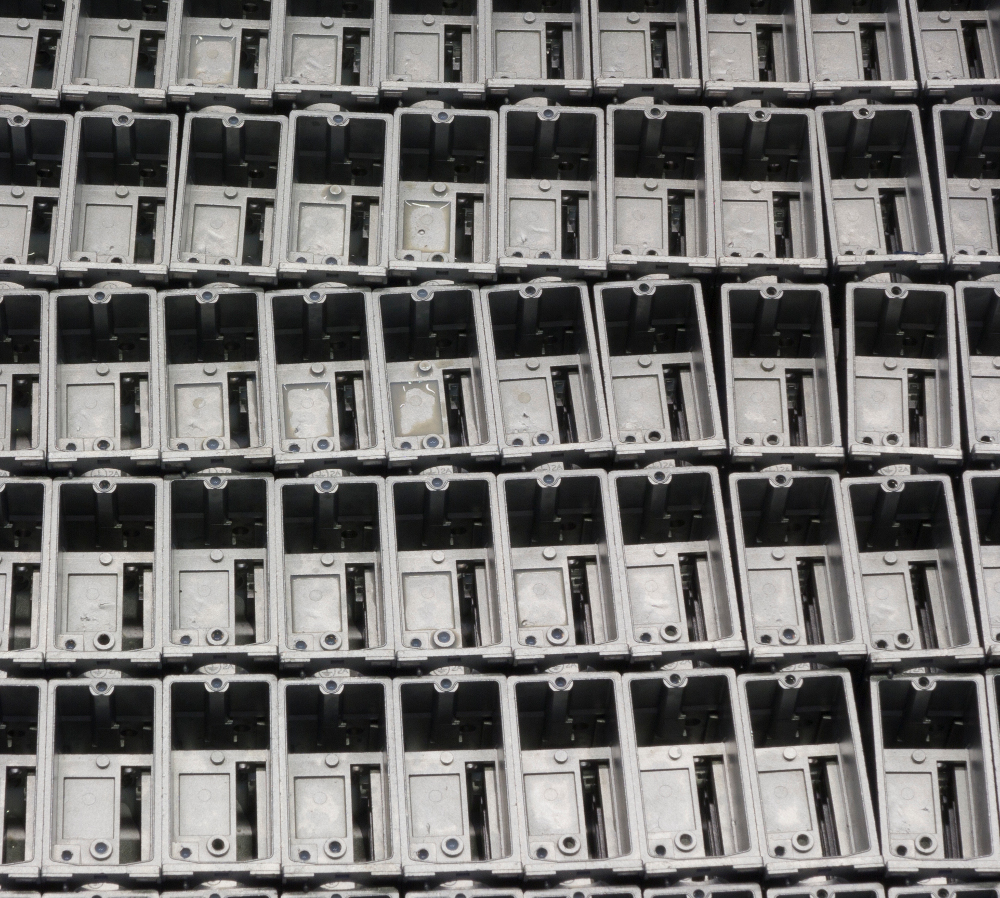

Industrialization of the product is a very delicate phase in the process of production of zinc alloy die casts: in fact it is in this phase that, after receiving the order from the customer, all the procedures that are necessary to start mass production are defined.

In this post, focused on the metrology laboratory, we will describe the devices employed to measure and test zinc alloy die casts intended for different market sectors.

In this post we analyze the activities of quality control in the production of zinc alloy die casts: a series of fundamental operations that accompany every phase of a project.

In this post we are analyzing how the qualities of zinc alloys become important competitive advantages in the production of lighting components. We will then review some products and their characteristics as case studies.