Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

Zinc alloys are renowned for their remarkable properties such as their robustness, resistance to corrosion and ease of casting. Over time, the evolution of manufacturing techniques has propelled zinc alloys to the forefront of a wide range of industries, including the automotive and electronics sectors. In this post, we will provide insights into the latest advancements unfolding within the realm of zinc alloys and their development, shifting from cutting-edge innovations to manufacturing breakthroughs.

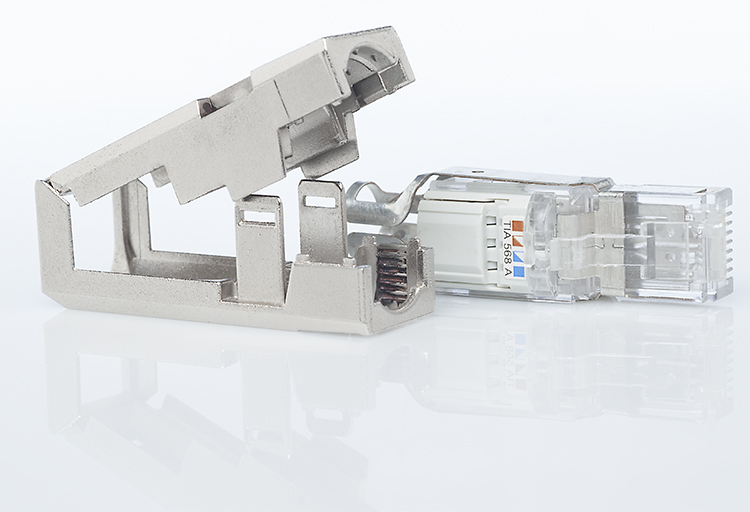

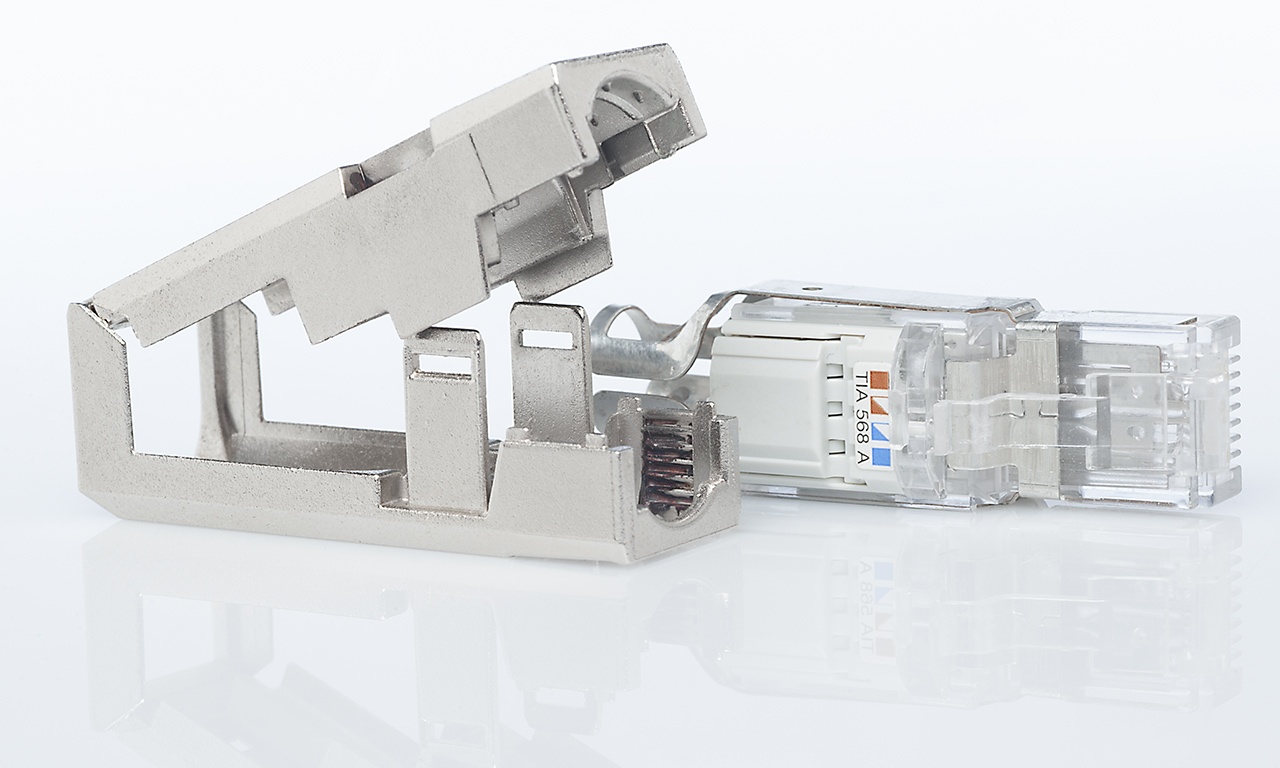

In the rapidly evolving world of electronics, manufacturers are constantly seeking innovative materials and manufacturing processes to enhance the performance of products, reduce costs and also improve the efficiency. One such technique that has gained prominence among different industries and also among the manufacturers is zinc die casting.

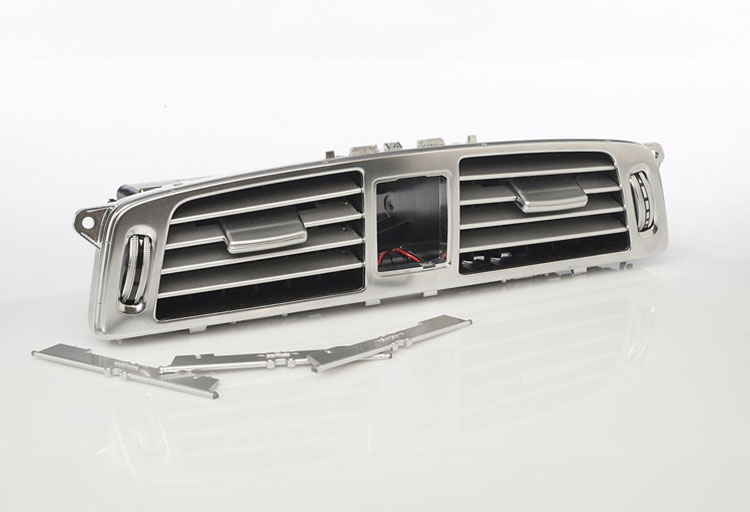

The automotive industry refers to the vast ecosystem of manufacturing, distribution, sales and consumption of vehicles designed for transporting people and goods. This industry includes a wide range of vehicle types that ranges from traditional internal combustion engine vehicles to the latest innovations in electric vehicles, autonomous vehicles and connected vehicles. The automotive market is not limited to the production of vehicles but it also includes associated services that are related to automotive industry such as aftermarket parts and solutions that support transportation needs all over the globe. The automotive market stands as one of the most influential sectors globally that is shaping economies, societies and individual lifestyles.

Zinc alloy die casting is a versatile and reliable manufacturing technology that enables the creation of complex components with high precision and strength for a wide range of industries. A crucial aspect of the production of zinc die-cast parts is the possibility of obtaining complex shapes adapted to modern design requirements, allowing for a harmonious balance between form and function to be achieved. In this post, we will explore the importance of achieving design excellence in zinc die casting and see how functional design can positively influence the success of a product.

Of all the modern manufacturing methods available today, the zinc alloy die-casting process proves to be one of the most efficient and environmentally friendly processes. In fact, these alloys offer numerous advantages in terms of environmental and economic sustainability, which we will see below.

In this post, we will address the main problems concerning the possible casting defects that could arise in the die-casting process and which would compromise the success of subsequent surface treatment. This treatment, which can be a galvanic or a painting, can be carried out for aesthetic and functional reasons.

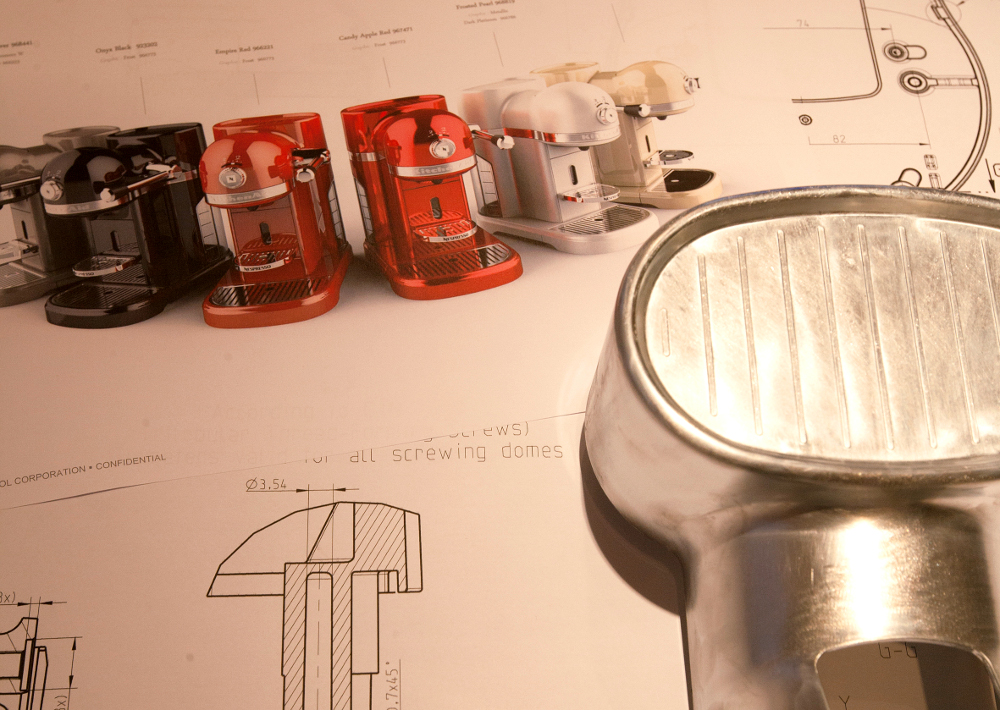

Zinc alloys are an excellent choice for creating and manufacturing appliance components. This blog post will explain why zinc alloys are widely used in this sector, highlighting their aesthetic, functional, environmental, and economic advantages.

Cavitation is a form of mold erosion that occurs during casting. In some critical areas of the dies, steel is removed and eroded by an aggression generated by micro-implosions of gases and vapors that occur during the filling of the cavity.

The rapid deterioration of the dies results in production stoppages and major maintenance operations that compromise the production efficiency.

In terms of mechanical strength, the breaking load is commonly defined as ultimate tensile stress (UTS), which is the maximum external force limit applied beyond which a material loses its functional specifications in terms of strength. Tensile strength tests vary according to the type of stress the material is subjected to, which we will describe later. In our case, are tests to be carried out on a component during production.

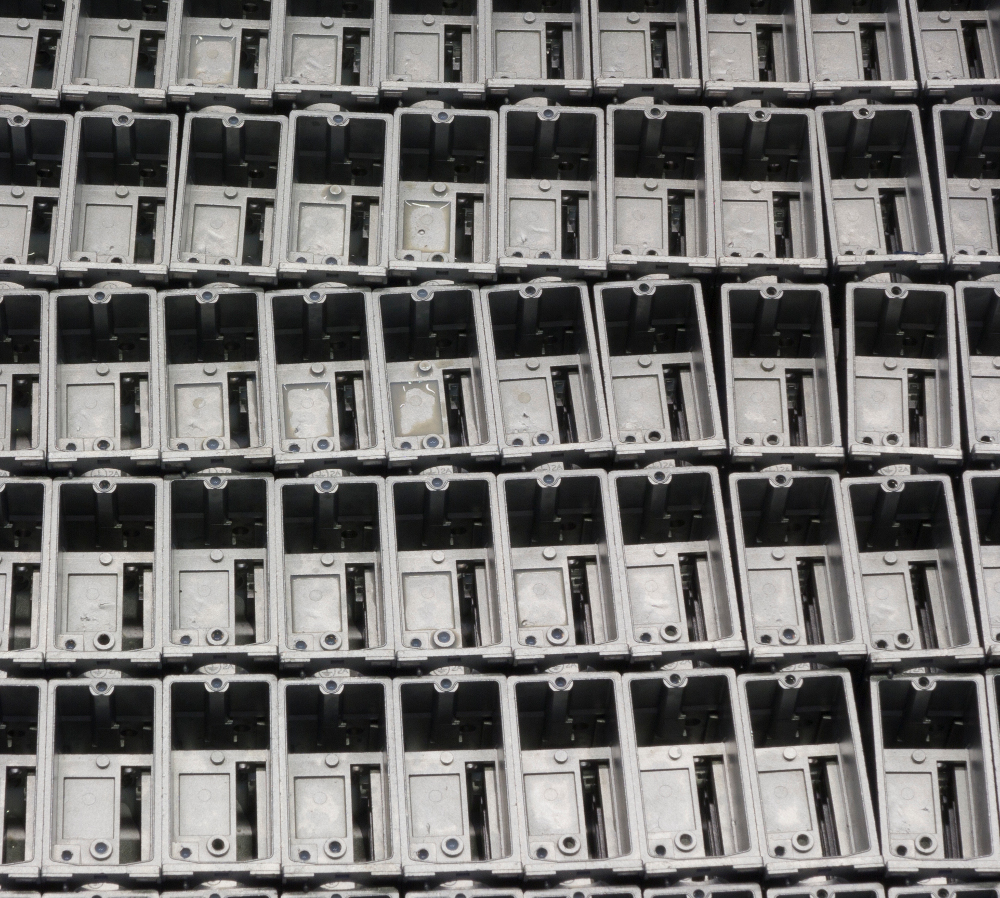

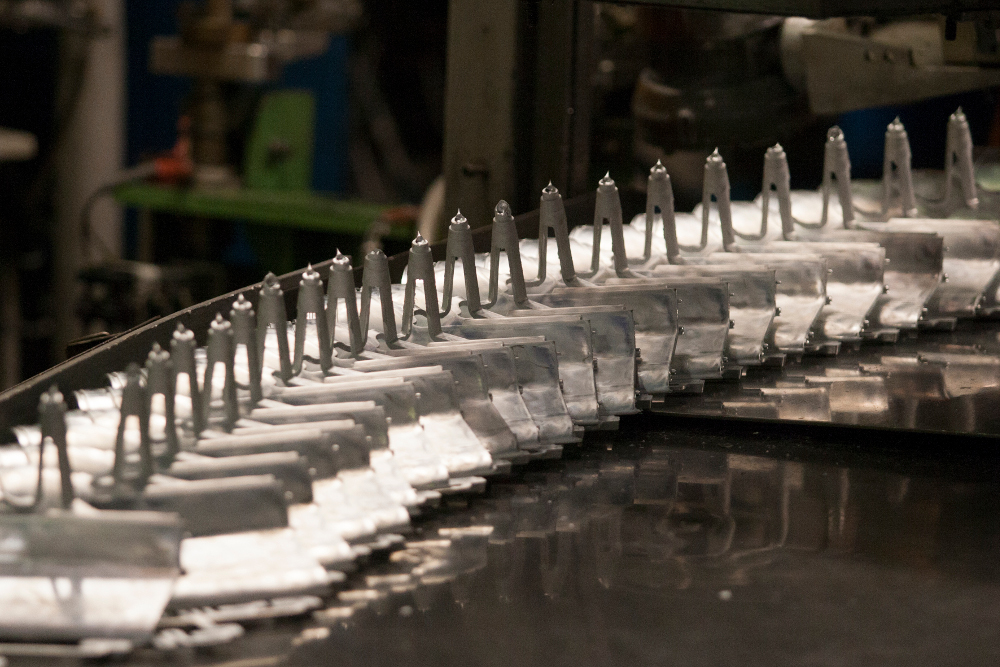

Zinc die casting is a process that consists in injecting the liquid metal under pressure into a mould, generally made of special steel, and letting it solidify. The die casting technique is the shortest way that leads from the metal in the liquid state to the finished product and has different fields of application (automotive above all, but also electronics, electromechanics, household appliances and in general all sectors that require non-ferrous metallic components).

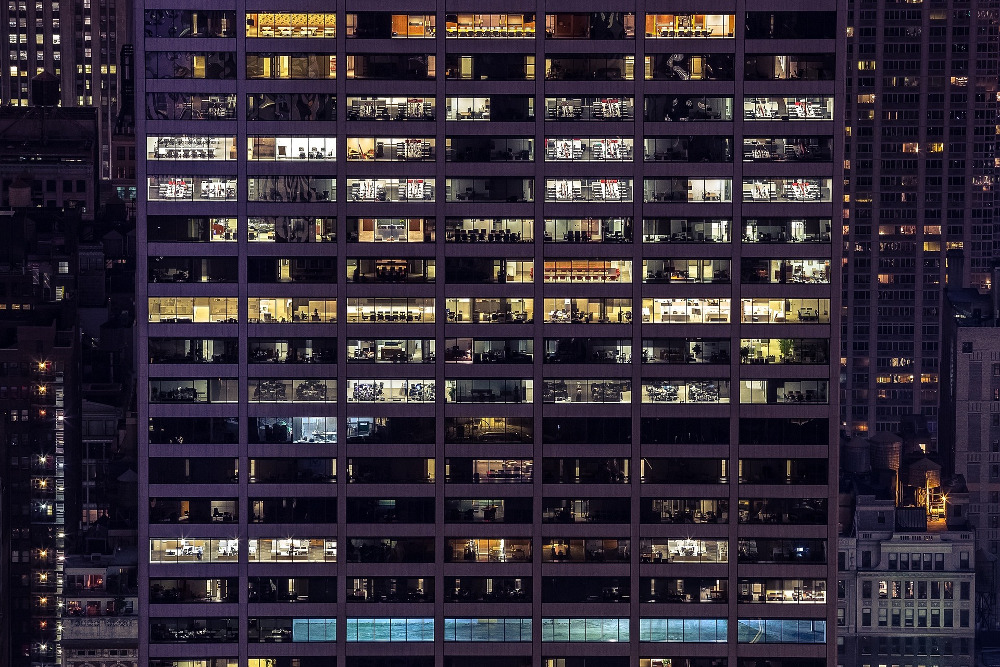

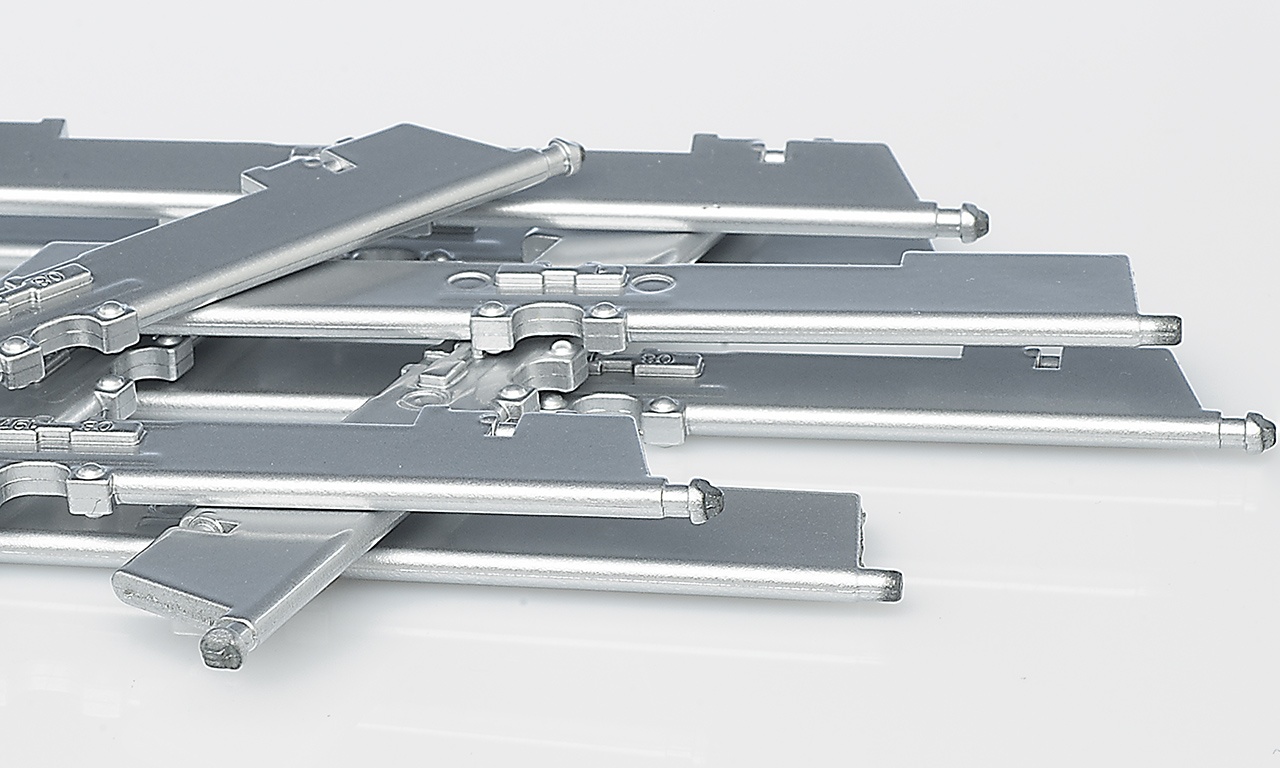

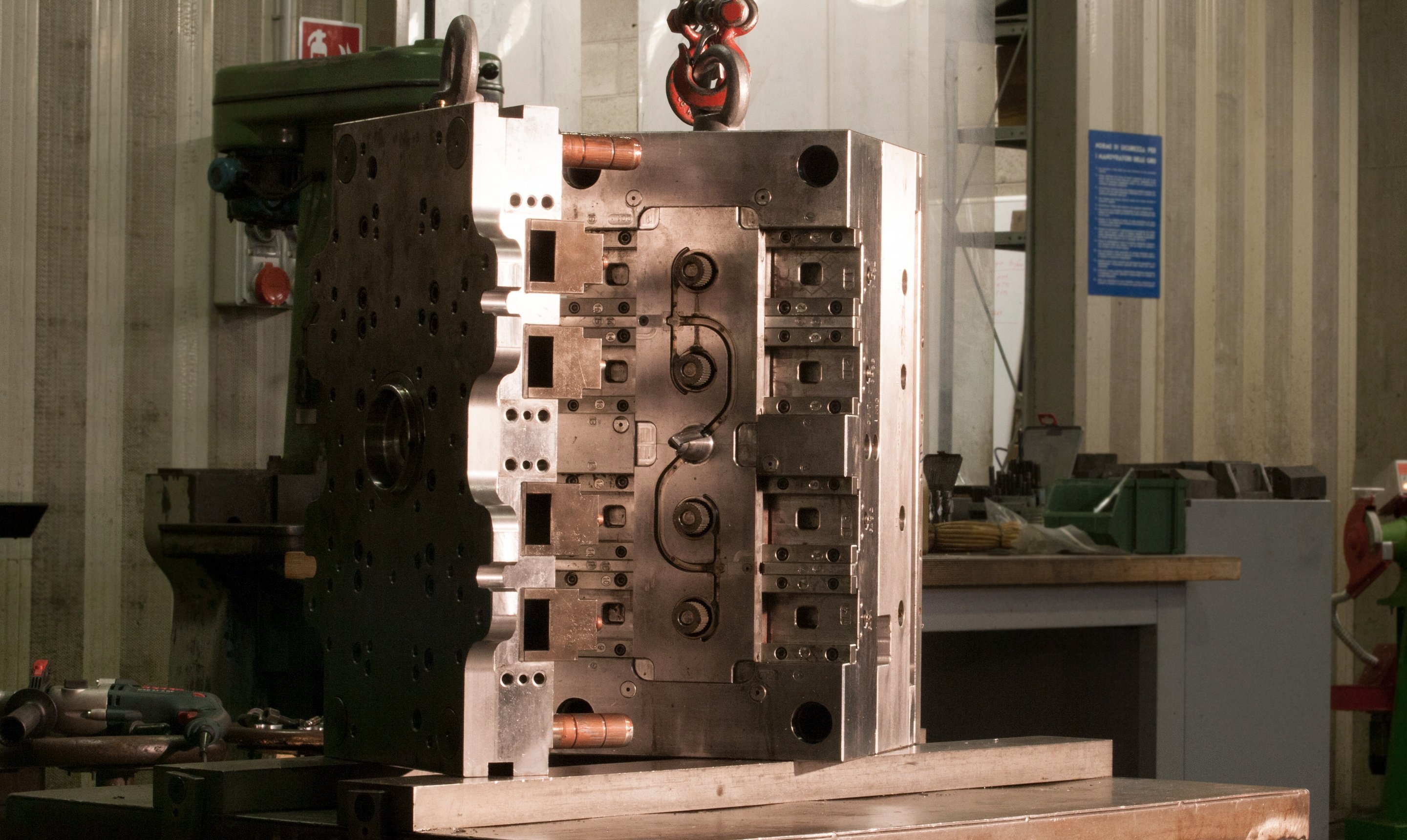

A vertical approach to production starts from product co-design and mold design, followed by tool manufacturing and the definition of the die casting process.

The production cycle is eventually completed by additional treatments or processes, which allows the die caster to offer not only die cast parts, but also finished goods. This can also happen through to the cooperation with external, specialized partners.

More specifically, this post will deal with chrome plating and painting of zinc die castings.

This post deals with the fundamentals of die casting machines and their role in the whole die casting process. Moreover, the post gives an outlook on the sector's future perspectives.

In this post we will focus on zinc alloy actuators of large air conditioning systems, explaining what they are and how their components work.

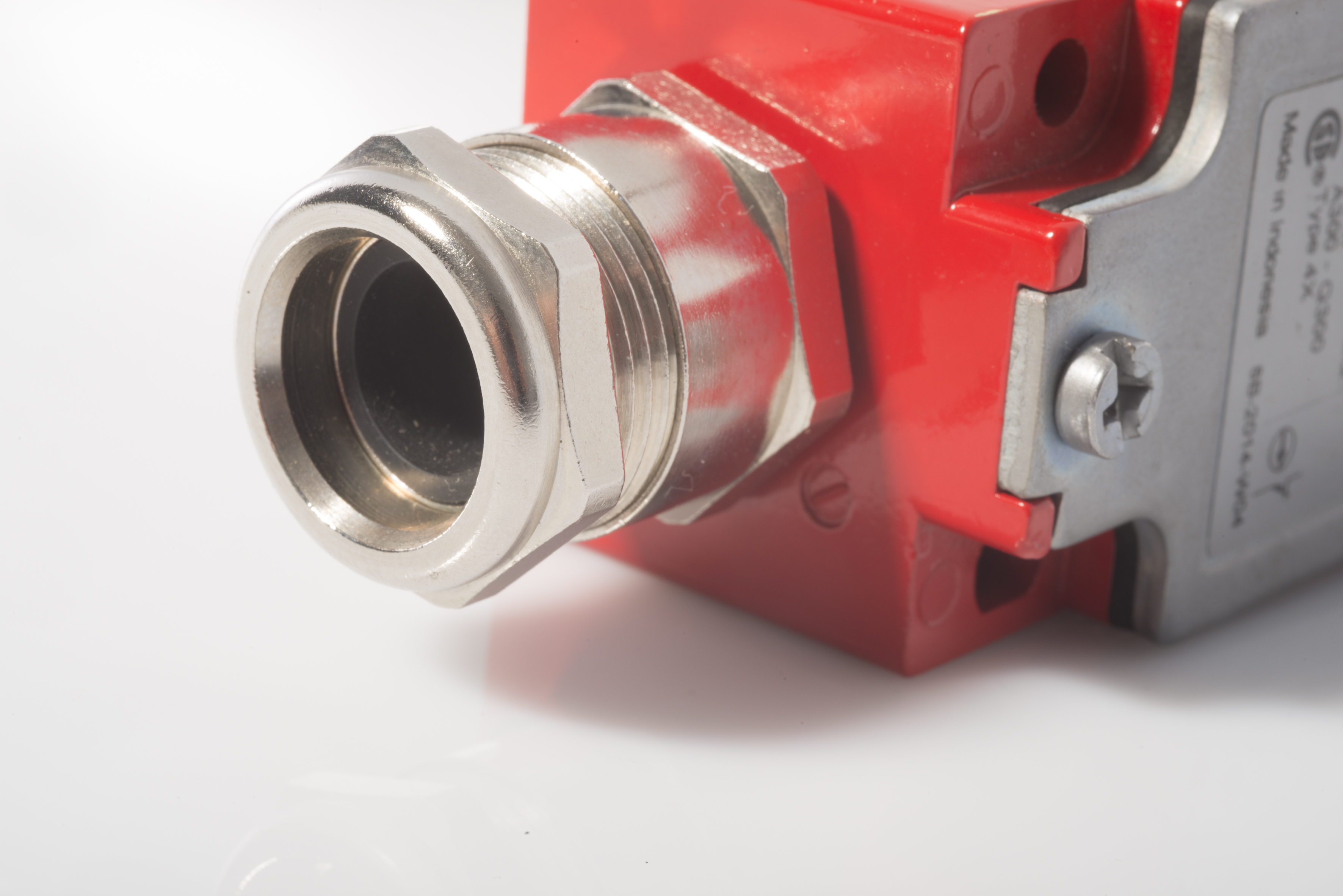

In this post we will analyze the properties of zinc components for electromechanical systems and then review some products that can illustrate the advantages that Zamak can confer to articles intended for this sector.

In this post we analyze proprieties and applications of Zamak components for textile machineries. The textile sector is indeed an interesting sector considering the continuous technological research which makes indispensable the use of high-performance components capable of responding to high technical and production requirements.

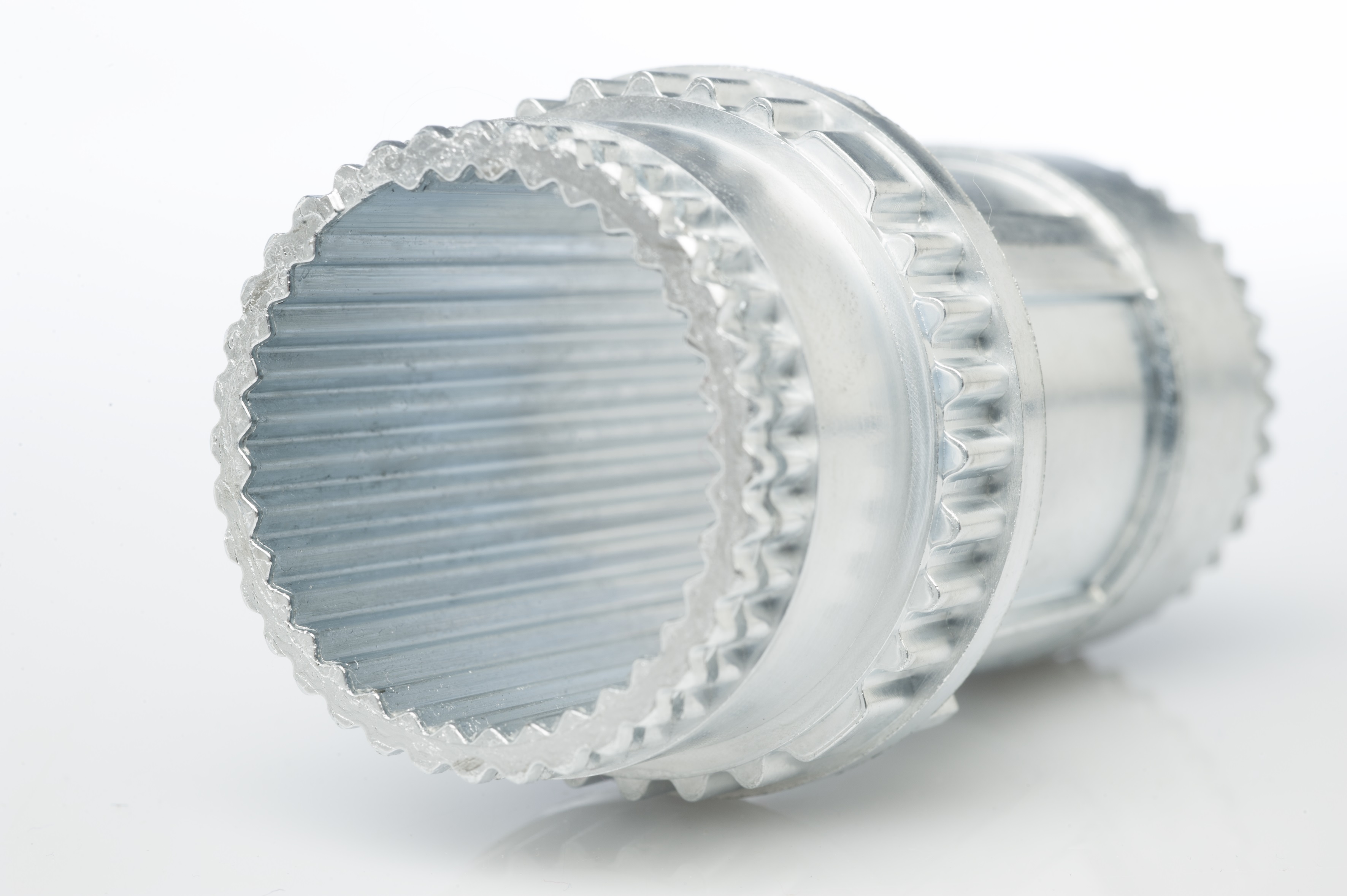

In this post we are going to briefly analyze the characteristics of zamak and to highlight its advantages in the production of components for electronic products. After that, we will review some components explaining how choosing zamak has made them more beneficial compared with similar products manufactured with other materials.

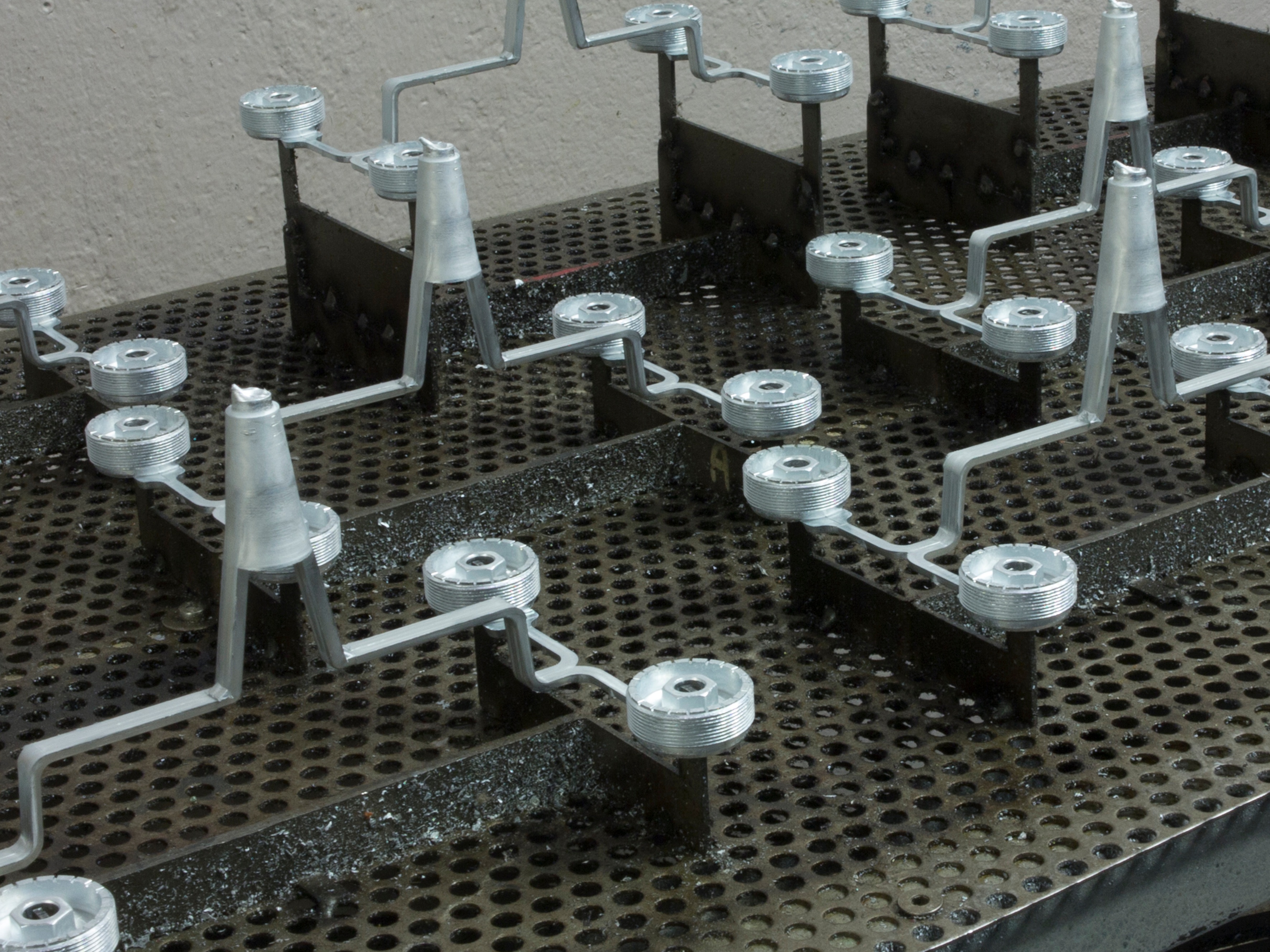

Industrialization of the product is a very delicate phase in the process of production of zinc alloy die casts: in fact it is in this phase that, after receiving the order from the customer, all the procedures that are necessary to start mass production are defined.

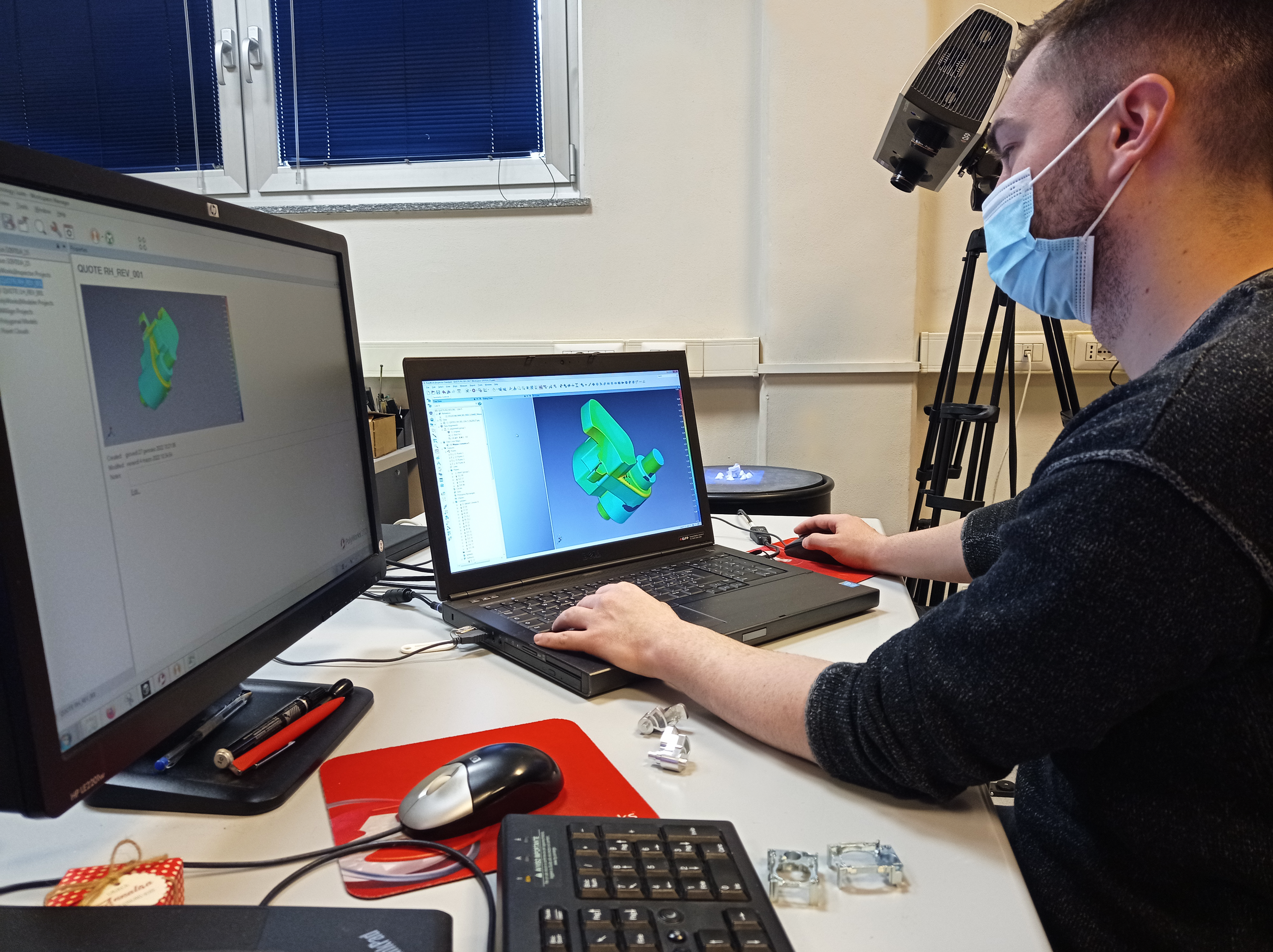

In this post, focused on the metrology laboratory, we will describe the devices employed to measure and test zinc alloy die casts intended for different market sectors.

In this post we analyze the activities of quality control in the production of zinc alloy die casts: a series of fundamental operations that accompany every phase of a project.

In this post we are analyzing how the qualities of zinc alloys become important competitive advantages in the production of lighting components. We will then review some products and their characteristics as case studies.

The versatility of zinc alloys can be tested in some sectors more than in others. A sector that offers great creative and design freedom is household appliances: in fact Zamak components for household appliances contribute to make the entire object unique, exclusive and immediately recognizable.

In this article we present some case studies relative to components made of zinc alloys for doors and windows. Zinc alloys are a perfectly suitable material for the production of components for the building industry and, among the various fields of application, doors and windows are certainly a growing industry with interesting developments.

Cost reduction in zinc die casting is an activity that shall be executed without affecting the quality and functionality of the component that is produced. All the activities that aim to increase productivity, to diminish scrap rate and to simplify productive processes, as well as the choices of materials and processing, are cost reduction strategies.

In this article, after briefly depicting the hierarchical structure of the automotive industry and the reference standard for the Tiers of different levels, we analyze the special partnership that exists between a Tier 2 automotive supplier and its customers, specifically examining the relationship of trust that can be established between a Tier 1 and a SME (Small and Medium Enterprises) Tier 2 automotive supplier.

Zinc alloys are a material that, if employed in die casting, allows the achievement of products with thin wall thickness. This property of zinc alloys results in an important added value because it permits the production of components with reduced weight and dimensions, thus benefiting from cost and raw material saving.

Thanks to their excellent mechanical and physical properties zinc alloys are a perfect material for die casting: they are indeed resistant, fluid, durable and rigid. But which are the best zinc alloys for hot chamber die casting? In this post we are going to analyze the different characteristics of zinc alloys for hot chamber die casting in order to define the best choice on the basis of the features that the final product requires.

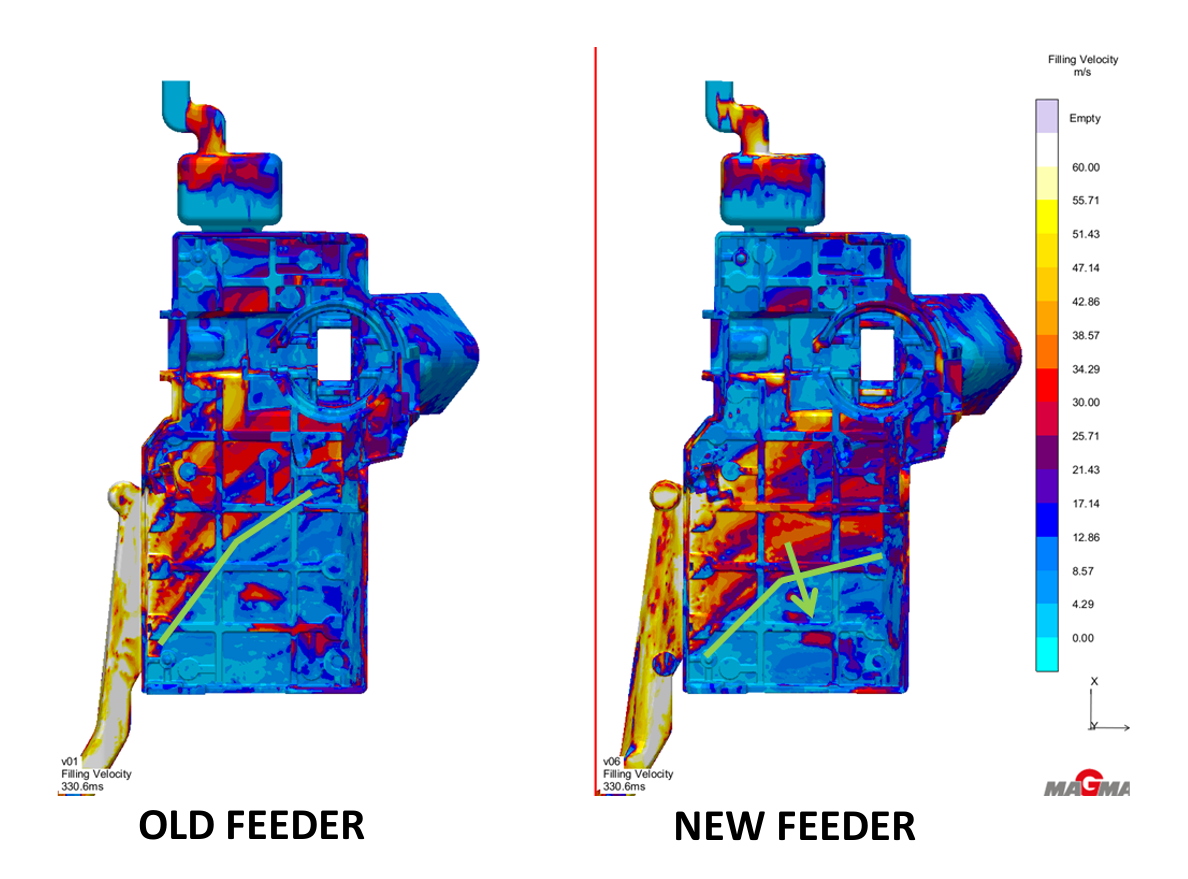

In this post we are going to analyze a case study that explains how to reduce casting defects through mold design. Due to mold wear condition components started to show superficial defects: Bruschi engineers have thus introduced improvements in order to reduce casting defects.

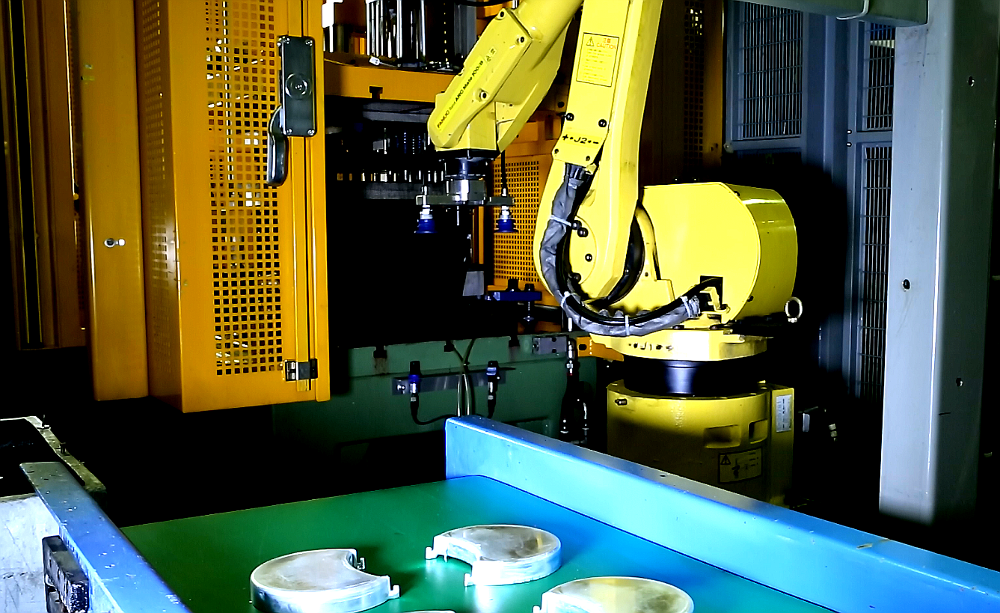

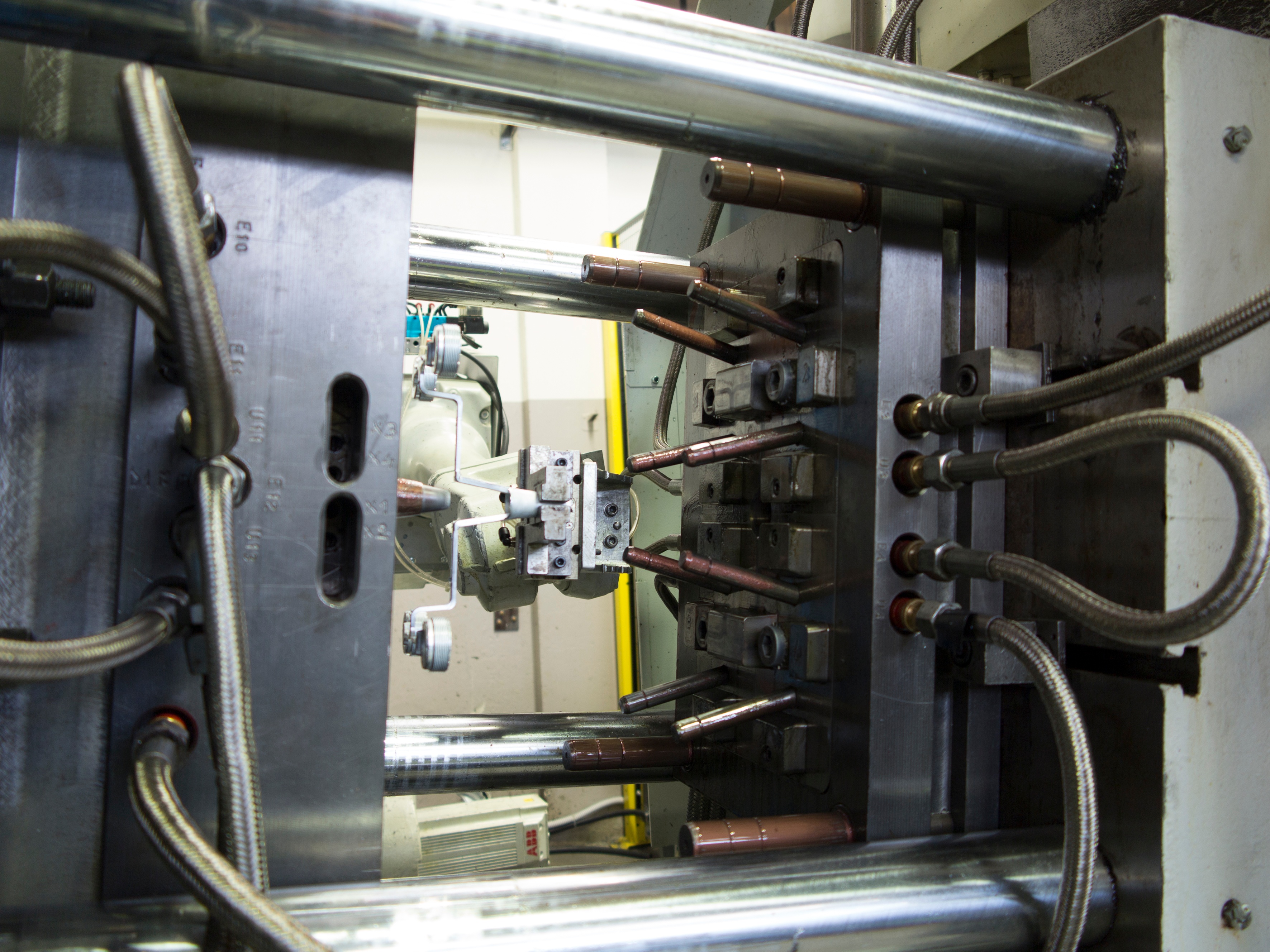

In this post we are going to examine a case study concerning a project for reducing manual operations through the introduction of automation, which has brought benefits to the whole production process.

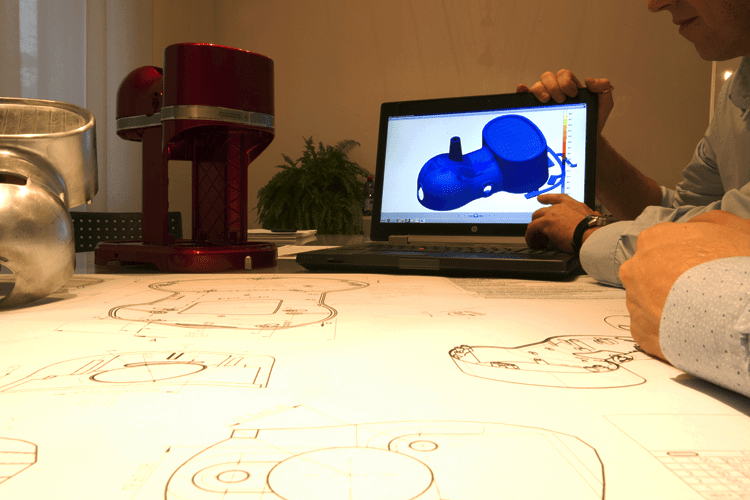

Zinc is a material that can be employed in several manufacturing sectors, including the branch of small appliances. The following post describes the main advantages of the use of zinc for the production of small appliances components, specifically of coffee machines components.

The term product design defines the process of designing a new product that has to be marketed in a specific business, taking into account not only its aesthetical characteristics but also its functions and its production cycle. Indeed, the product must meet the final user expectations while simultaneously be compliant with the production process.

Process improvement, in the zinc die casting industry as well as in many other manufacturing sectors, consists of a series of actions undertaken to enhance production times, to reduce costs and, consequently, to obtain results that satisfy client’s requests in terms of timing and performance.

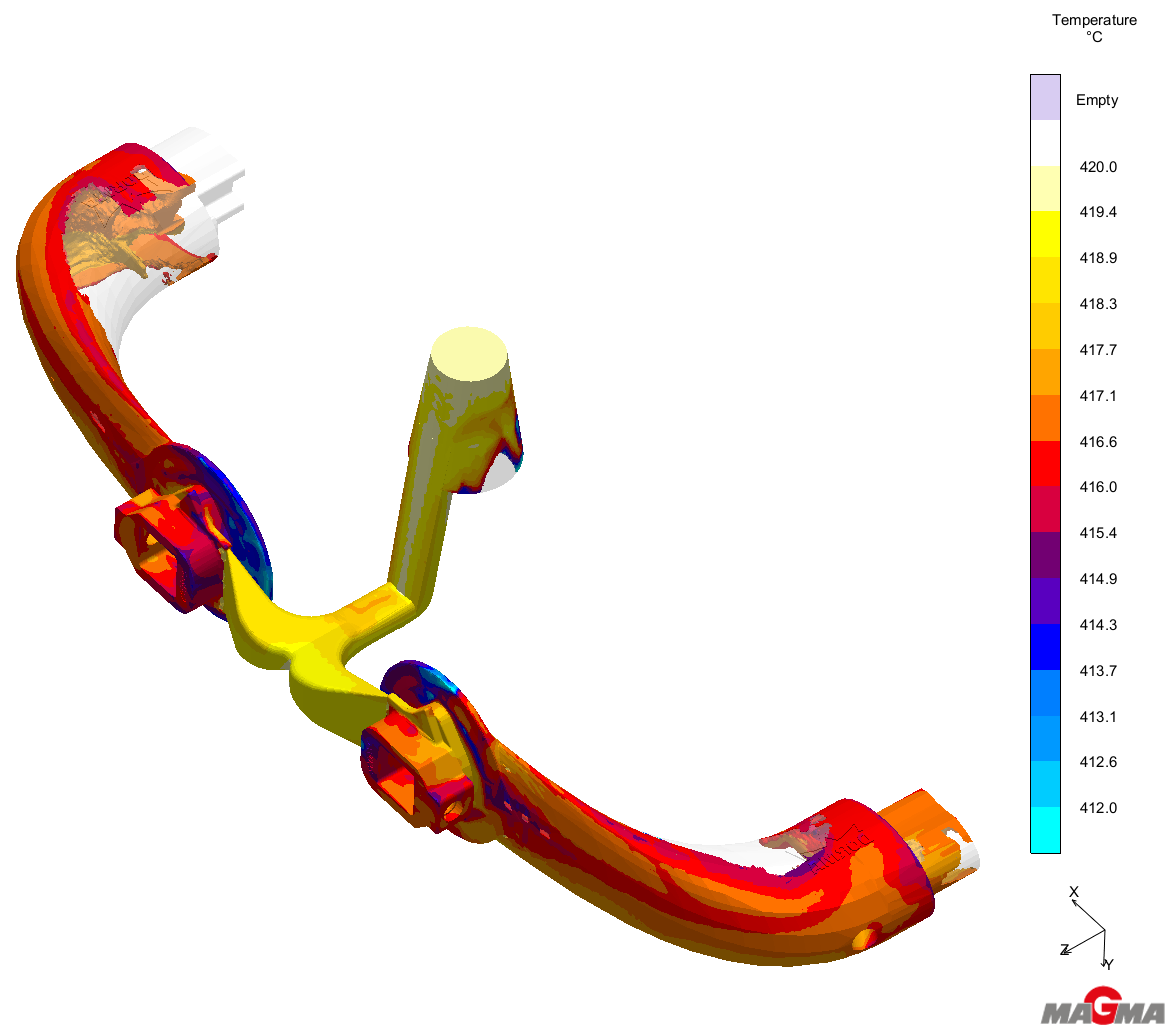

In this post we are going to explore a case study dedicated to surface aesthetical quality in automotive. This post is part of a series in which we explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of real life cases.

In this post we are going to describe the business philosophy of functional beauty. Starting from this philosophy, Bruschi created Nespresso KitchenAid Artisan 5KES0503, a design coffee machine that led the company to the victory of the prestigious European Zinc Die Casting Competition for design in 2016.

In this post we are going to explore two case study: the first one is dedicated to resolving issues with die maintenance for a component of automotive sector, while the second one regards the optimization of set up parameters for a component of small domestic appliances.

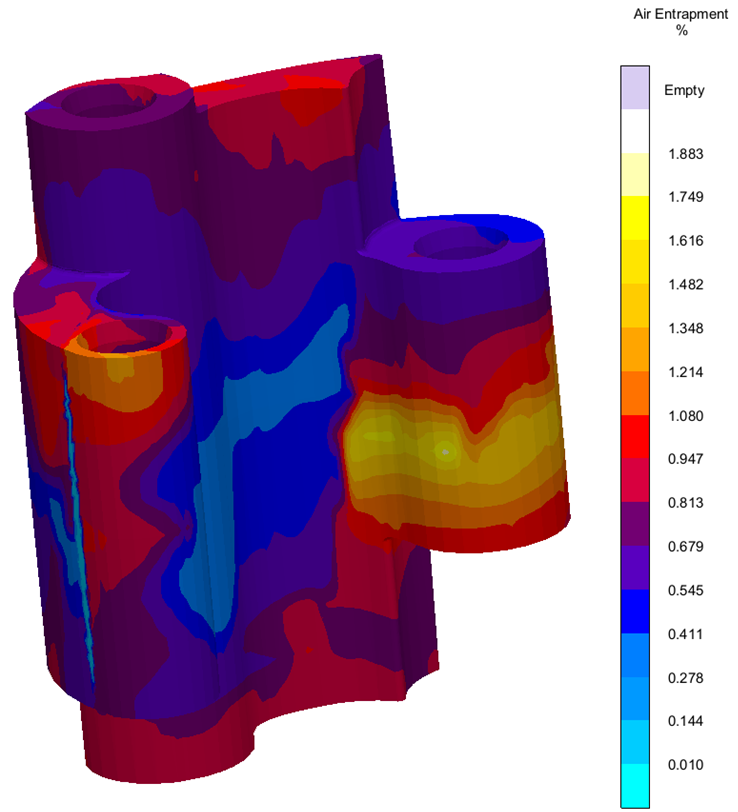

In this post we are going to explore a case study dedicated to the improvement of mechanical characteristics, by reducing shrinkage porosity in a component for building sector. This post is part of a series in which we explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of real life cases.

The process of zinc die casting is highly popular for making parts in building and industrial fields, but its most common application is in automotive industry. In fact, cars have different parts that can be crafted through die casting, so much that the modern process of die casting originally started for automotive industry.

In this series of posts, we are going to explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of different case studies, in which simulation played a crucial role.

In this post we are going to list and define the most common surface treatments for zinc die casting and their effects, and we are going to present three case studies in which the application of a specific treatment helped in improving the overall performance of the component.

In this post we are going to list some of the most common processing techniques for metal finishing and their effect on the surfaces.

In this post we are going to describe what is meant with surface finishing and we will explain why it is important to take them in consideration from the designing phase of a component, giving some advice for the optimization of the most critical points.

In this post we are going to discuss the advantages of involving suppliers in procurement strategy, and how they can impact the final result of a VA/VE analysis.

In this post we are going to explain what Value Analysis / Value Engineering is, starting from its history up to why it is so important for manufacturers today.

In this post we are going to analyze some surface defects in die casting linked to errors in the painting process of zinc die cast products.

In this post we are going to list the most common defects in zinc die casting surface treatments and explain how to prevent them. We are going to analyze the following defects: blisters, pitting, burnings, nodules and flaking.

ZAMAK molding is the creation of components using zinc alloys for die casting. In this post we are going to discuss how the choice of the alloy can affect the final result of hot chamber die casting.

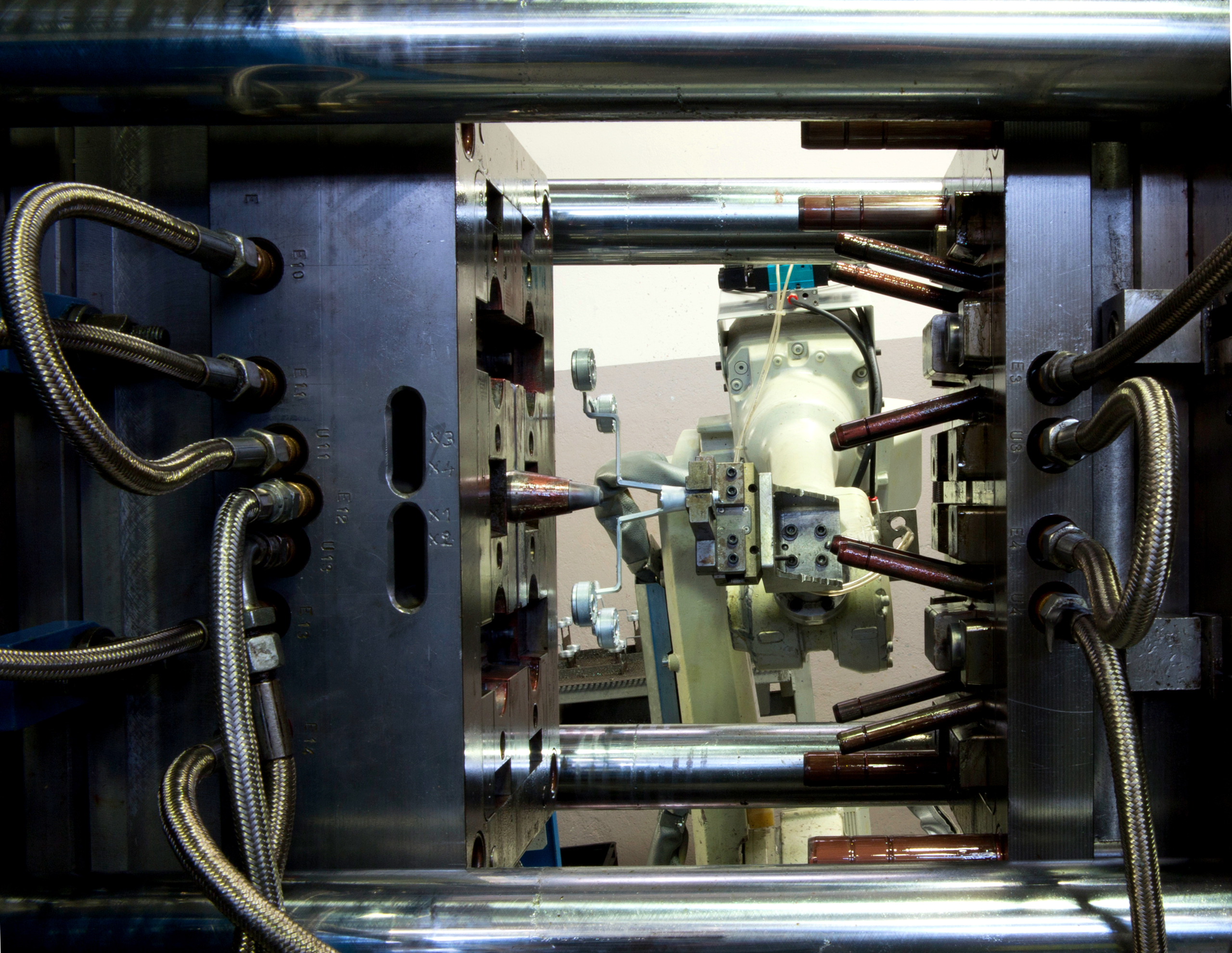

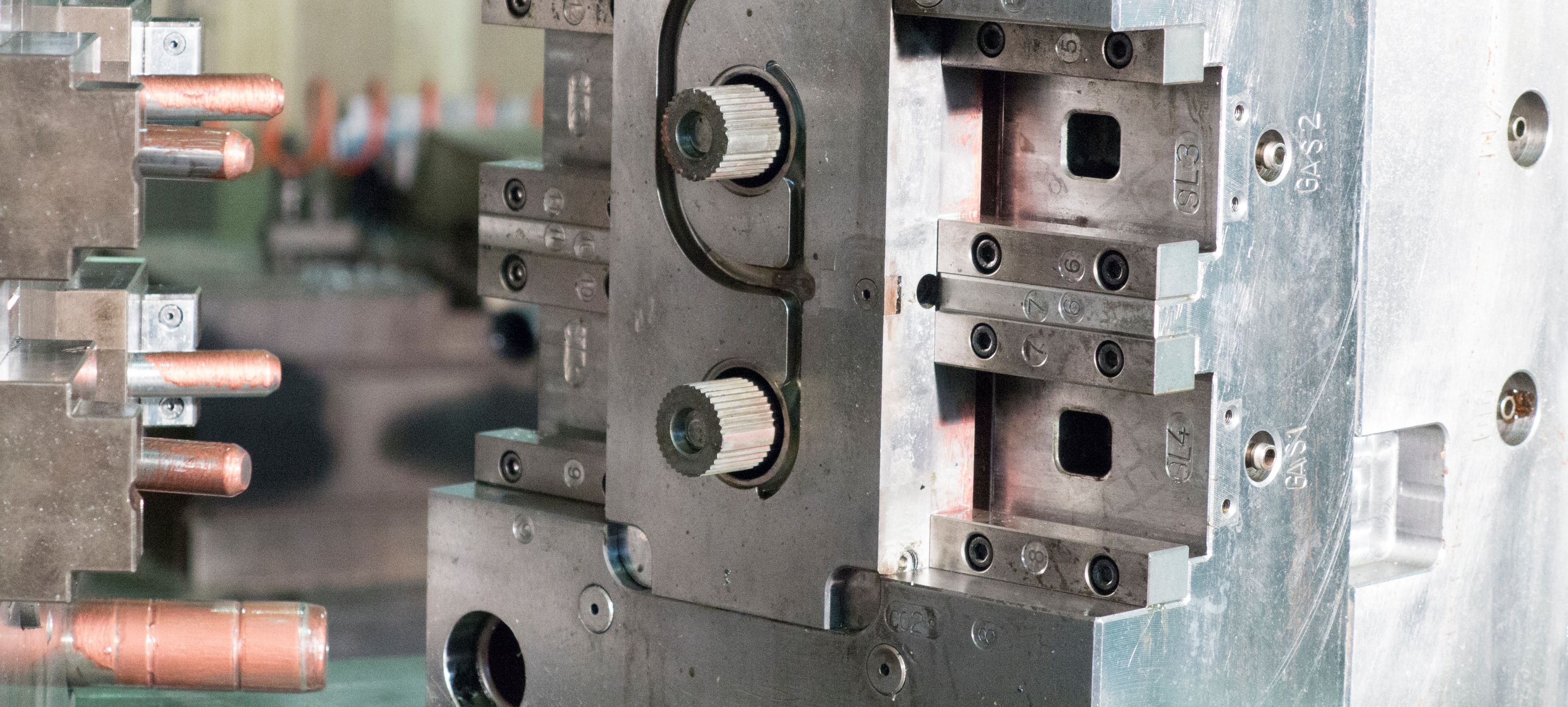

In this post we are going to describe the designing process of a hot chamber injection system, useful for casting process optimization.

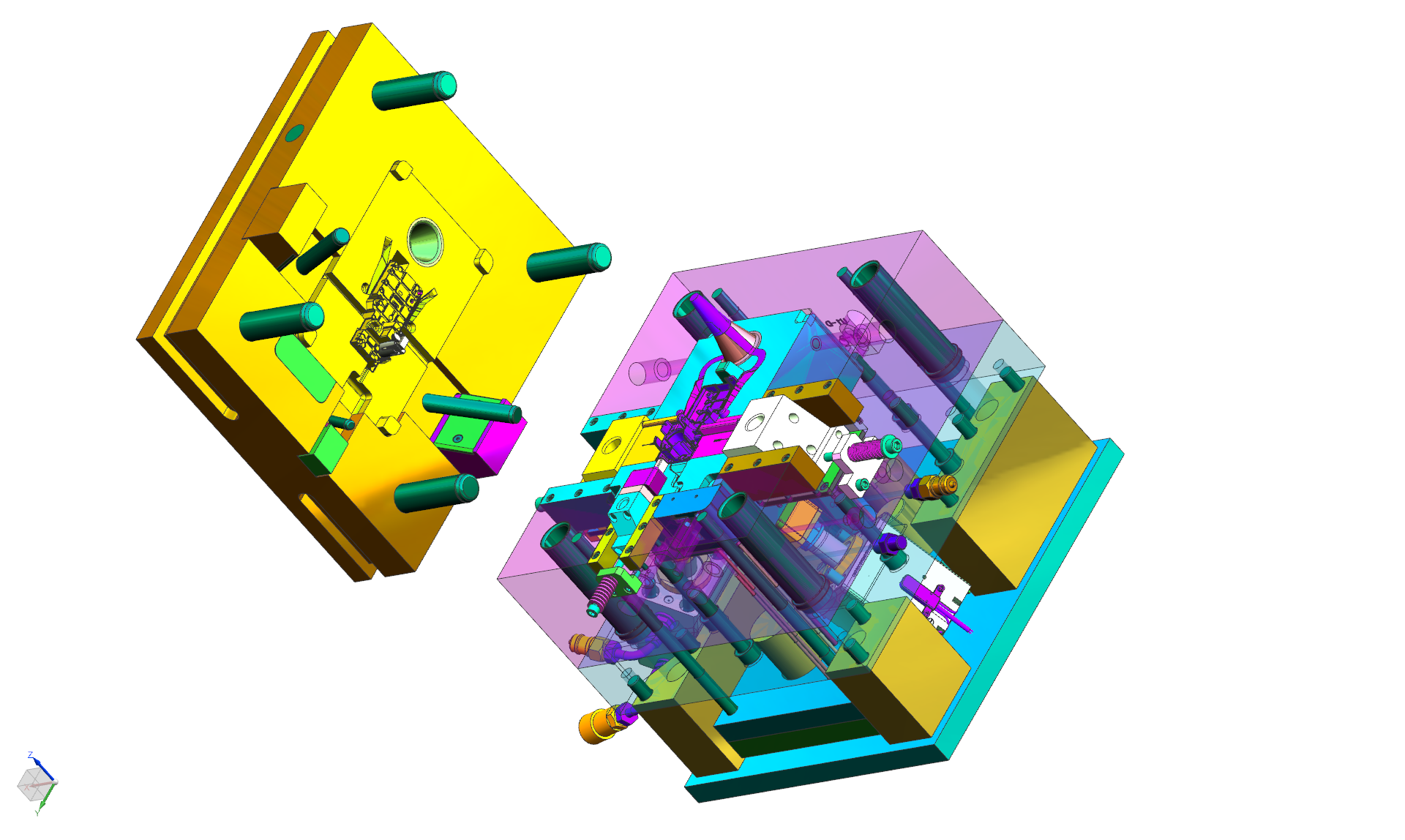

In this post we are going to fully describe the process of mold design for high pressure die casting.

In this post we are going to discuss some of the most common defects in die casting linked to mold maintenance, and how they can be fixed by the maintenance department.

In this post we are going to discuss the structure of die casting cycle time and how its optimization can bring various benefits for the company.

In this post we are going to describe in detail the relation between mold maintenance department and foundry: how the inclusion of maintenance department and tooling department in the production area can bring actual economic advantages and time saving.

In this post we are going to discuss how it is possible to reduce components weight while maintaining their functionality through the use of co-design.

In this post we are going to talk about how the use of a HPDC simulation software can benefit the production.

In this article we are going to analyze product design for die casting through the study of a DFM (Design for Manufacturability) and suggesting a way to optimize and speed up the process: co-design.

Having a metrology room inside of die casting plant, focused on the dimensional control of the components, assures the requested dimensional quality of production in order to reach customer's needs in terms of lead time and minimize risks.

Commodity prices volatility is driven by worldwide demand and other variables: it is basically about rise and fall, but there are different options in order to optimize the cost. In particular, this article focuses on metal and tries to find solutions on how a die caster can help a manufacturer to avoid the increase of production costs.

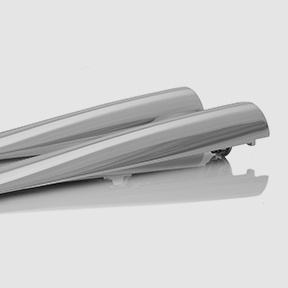

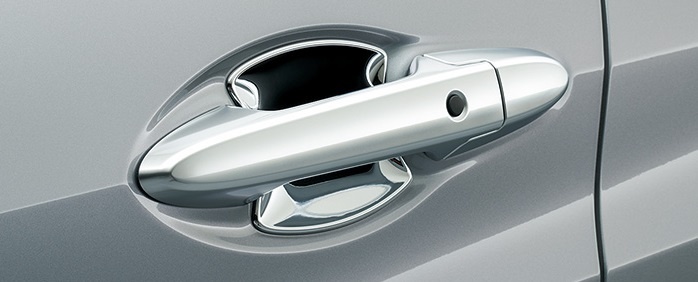

Developing automotive die casting exterior parts could be a solution to allow a wide scale of surfaces, structural characteristics and production capabilities. In details zinc alloys allows expanded styles in shape construction and precision in tighter angle tolerances.

In the current industrial context, reducing production times will become ever more crucial to offer customers an optimal product in the shortest time possible, with consistent cost savings.

By using zinc pressure die casting is possible to obtain innovative shapes and unconventional finishing: in fact zinc alloy is the ideal material to produce components or products aligned to customers’s aims, by reaching higher aesthetic values.

In this article we are going to analyze a particular corrosion test called Salt Spray Test - SST, normally used to test coatings for automotive parts, in order to test their salt or mist resistance.

Zinc is very versatile material: a combination of factors makes it a unique material from various perspectives, certainly from a cost point of view. According to that, the application of die cast zinc alloy components in the automotive industry can be an efficient solution to reduce production costs while maintaining the high levels of resistance, service life and hardness required by that sector.

Just like atmospheric environment, which is different for corrosivity depending on where people are located in the world, the same is for metal corrosion in automotive parts: for example in Sweden the automotive environment is quite aggressive because of humid climate and of the use of de-icing salts causing metals corrosion.

One of the main fields of application for zinc alloy products is surely the building sector. Depending on the position of the component and its visibility, various surface treatments are required to improve aesthetics and functionality.

Zinc die casting finishes are processes applied in order to modify surfaces of manufactured items, products or components with the purpose of reaching client requirements and improve functional and aesthetical quality of a product.

The main die casting defects which occur during die casting can be divided in categories related to different phases of production process: die casting, pre-finishing, machining operations and surface finishing. In particular in this article we are going to analyze defects related to the first category: die casting.

Black zinc is a zinc plating treatment which gives aesthetic and functional characteristics to products' surface. In this article we are going to deeply and technically analyze this treatment but, first of all, it could be useful to have an introduction on zinc plating main characteristics and which different types are most commonly used.

The automotive industry has requirements that are both functional and aesthetic when designing a component which should be produced by using die casting process. The main aspect a die caster will seek to ensure is oxidation prevention, therefore requirement on component is to extend resistance to atmospheric agents.

It may seem impossible but it is not! Reducing costs adding a die casting finish is really possible. The trick is just trusting your supplier and its expertise: collaboration with it in co-design terms. Starting a collaboration with suppliers can help clients to find a suitable solution to obtain the same requirements: with new solutions, but less costs.

Diecast finishes are every industrial processes applied to modify product or component surface in order to improve its aesthetic or technical quality. These processes are applied to improve or modify electrical conductivity, remove burrs and other flaws and for many other reasons. Furthermore, diecast finishes allow obtaining the desired aesthetic feature and coating durability.

Die casting surface treatments are operations that lead to obtain a finished product starting from the casting aiming at increasing aesthetical and functional characteristics of a product or component. Can be either production cycle last phase or a step, where component surface is prepared for other following treatments.

In die casting, zinc die casting finishing process might improve the product appearance and performance. Zinc die casting parts can be submitted to different kinds of post treatments for many reasons, such as improving a product appearance, conferring resistance to chemicals, corrosion and wear, improving or modifying electrical conductivity and removing burrs and other flaws.

Shrinkage porosity defects are cavities inside components which can cause material weakening and, if positioned on surface, can worsen aesthetic quality and corrosion resistance.

Zinc die casting process can have important advantages compared to other manufacturing process: for example can lead to major cost savings during production cycle, allows to create complex product shapes and is possible to eliminate unnecessary assembly operations combining multiple components into a single one.

Nowadays using technology software such as die casting simulation allows optimizing the whole production cycle. Today’s ever-changing international marketplace is highly demanding and challenging: using the newest tools from supplier side mean giving clients innovative solutions to reach their expectations. The following article will explain how to obtain consistent savings with die casting simulation.

Choosing the perfect zinc die caster is an important issue: this choice could determine the good or bad outcome of a product. In order to reach clients’ expectations is important to consider every production aspect: to organize it in the best way possible it is important to analyze the entire production process.

There are different types of suppliers that are involved in die casting process: the raw material producer, the toolmaker, the die caster, and experts of secondary operations. The most important supplier involved in the product design phase is the zinc alloys die caster. In fact the supplier should foresee in advance the casted product performance, its aesthetical requirements and its total costs.

Zamak die casters cannot be choose without a mindful analysis. Choosing the right supplier can be a tough issue: it is fundamental that zamak die casters are able to understand if die casting is the right choice for the production of the component requested, or instead advice the client to use another technology.

Die casting companies that use simulation tools can give important benefits to its customers. Using these simulation tools can allow to obtain an important saving in terms of money and time in different ways. In this article we are going to analyze benefits of simulation during the development of a new component or product.

In this post we are going to see how the involvement of zinc die caster supplier can lead to improvements in the diecast quality and from a cost point of view, thanks to the following activities: co-design, simulation and the choice of zinc.

The main benefits of using Zinc alloys are accuracy, machinability, thin wall capability, castability, dimensional stability, and joining feasibility. Zamak die casters should help their customers reduce manufacturing costs, which in that industry can be divided into three main fields: raw materials, labour and process.

The most important thing that a designer needs to consider before product design is to have an unlocked mind from usual and common mechanical processes. It is fundamental to point out that with high pressure die casting it is possible to create products without ordinary shapes and not to be bounded to customary morphology.

Industry 4.0 tries to gather every phase of production process into simulation. In particular in die casting engineering, simulation has to consider several points: productive plant, die casting tools, automation tools, cooling tools, secondary operation tools.

In order to apply a cost reduction in casting the designer should have a global view of the entire process. Casting process is composed of different phases that allow zamak becoming finished and packaged product: in this post we will examine the six stages of die casting process and analyze how and when it is possible to reduce costs.

Among die casting services a supplier may offer to its customers, co-design is fundamental to realize a product with specific technical requirements. Co-design is the collaboration between the client and the die casting supplier, and it is fundamental to realize a product that has technical characteristics requested for its functionality and its aim and is at the same time in compliance to the process of die casting.

The most important element selecting the materials for the production and processes is trying to minimize costs of the product and its production. Producing, finishing, delivering and assembling costs depend on a wide range of factors. In this post we are going to understand in which areas companies can obtain costs savings.

A customer oriented company should focus on a co-design service that can help to cut costs. Manufacturing costs of products can be categorized into: raw materials, labor and process. In this regard product engineers are always trying to reduce production and material costs but also to maintain the quality of the product: value analysis and value engineering (VAVE) is really fundamental to reach this goal.

To predict shrinkage porosity and other defects, simulation is increasingly used nowadays, as these software require less development cost and time than experiments. Only some specific simulation programs, however, take into consideration the effect of back pressure in the cavity in die-casting. In this article we are going to discuss: what is shrinkage porosity, causes of the defect and how to avoid it with simulation.

Product design is an important part in die casting engineering which can be optimized adding a co-design process. Co-design activity is composed of three different phases: prrocess design, cost analysis and product design.

Zinc casting alloys provide a better combination of strength, toughness, rigidity, bearing, performance and economical castability than any other alloy possible. In fact their properties often exceed the ones of other alloys such as aluminium, magnesium, bronze, plastics and other cast irons. For its properties of strength and duration zinc is the perfect choice for saving time and money.

In Bruschi an important evolution of the customer service has given many concrete advantages for the company and its clients: in terms of cost saving, risks minimizing and a better logistic management.

Supply chain is the management of the flow of goods and services from the point of origin to the point of consumption: a cluster of activities done in order to meet customer’s requirements, to coordinate the suppliers, clients and the company itself. In this post we are going to describe how a well-structured supply chain can lead to costs saving.

We are in the middle of a business innovation that sees a revolution in how companies create values in particular in their approach to innovation. A real revolution is given by combining technology and industrial assets.

In high pressure die casting industry both suppliers and customers are always looking for the best solutions in terms of part load, costs and times for development and manufacturing processes.

There can be many suppliers involved in the die casting process such as the raw material producer, the die caster, the toolmaker and others representatives of companies involving secondary operations. The right zinc die casting supplier is able to support its customer, anyway it is fundamental that the designer has knowledge of the material features and the process phases.

There are rules that need to be considered to design products or components in pressure die casting. The application of these advices will lead to a design that is logical, efficient and cost saving. In this article we will list some critical points to be taken into account when designing pressure die casting components.

Choosing the right supplier, in a wide range of zinc die casting manufacturers, is a tough issue. Having the right partner helps to reach planning and project goals and can be useful to develop a product or component in a co-design activity, while a bad partner could be a hard obstacle to catch the goals.

The history of Bruschi is linked to the concept of growing change. This concept, in general, assumes the capability to adapt to new conditions in accordance with the environment, interacting with different factors that are part of the system: in a continuous improvement imposed by the ability to win and face all the issues found on the way.

We are in the middle of a new industrial revolution: the fourth one. It’s called Industry 4.0. This term, used for the first time in Germany in 2010, is related to the digitalization of information. In this post we will see how Bruschi is approaching Industry 4.0 and how this new industrial revolution is affecting its business.

For a correct approach to product design for die casting it is important that every part involved has knowledge of the industrial process. These competences need to be part both of the client and the supplier's technology, to allow a co-design work that can improve the product or the component. In this article we are presenting two different perspectives of zinc die casting technology: product design and process design.

The term automation defines the introduction in a manufacturing company of technical tools and processes aimed at reducing or even eliminating human operations. The incorporation of automatic equipment produces several advantages, such as time saving, costs reduction and better quality outputs, thus achieving customers' satisfaction.

Excellent workplaces are organizations where the collaborators are enthusiastic about what they do and trust people around them. It is not just about skills, knowledge or expertise: but it is about the way to approach issues.

In this post we are going to describe the benefits of die casting simulation, how to avoid non-compliant products creation, how to avoid material waste and how to save time avoiding empirical tests.

Working in Bruschi means passion and innovation. These two characteristics are the guidelines that every employee of the company has mixed to technical skills, expertise and capacity to face issues and challenges. In this post we are going to see how the invention of the vacuum valve has brought a relevant competitive advantage for Bruschi.

The concept of die casting mould design concerns the design of the mould but in general it defines the entire process of die casting. It’s a phase of the product industrialization that has clear characteristics to avoid many defects: for example cold laps.

In high pressure die casting, the filling process is crucial for the product esthetical quality and mechanical characteristics, for reducing scraps and optimizing set up parameters, and also for the maintenance and life cycle of the die.

A mold, in die casting terms, is a mechanic tool that allows to replay a product endless times, considered manufacturing limits, among the consolidation process of the same metal molten before. The mold is then the first actor in die casting field: so die casting mold design is a core activity to reach the customer needs.

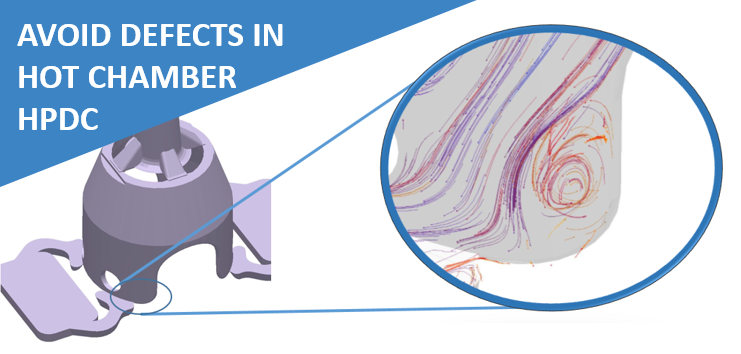

Hot chamber hpdc is a die casting process in which high pressure is used to force molten metal through a mould. The use of pressure let the metal flow through the die and leads to great qualities of castings especially when a perfect surface is needed. In hot chamber hpdc, the supply of molten metal is an integral part of the casting machine for the manufacturing operation.

Reducing scrap could be your next way to cut costs in die casting process. Saving allows you to invest in research and development, maybe right to find new ways to reduce scraps: in a sort of golden circle which allow your company to be more performing. In this case using the right methodology and the right tools the solution could be suitable for your company.

In this post we are going to describe both tangible and intangible benefits of simulation in die casting design. These advantages are cost reduction and value addition.

The activity of co-design is our way to support our costumer in the initial phase of project or improving existing products or components. Design products or components means face the complexity. Co-design is a crucial phase of the entire process of product design and Bruschi can help you in the all stages, such as simulation, prototyping, testing, accelerate time to market, process optimization.

In this blog post, we'll dive into the most common defects that can appear in high pressure zinc die casting and a possible way to avoid them: gas porosity, shrinkage porosity and leaks.

Zinc is the ideal material to turn your idea into product. Zinc die casting means innovative shapes and unconventional finishing: zinc turns your ideas into a product. Our process in Bruschi allows high precision and eliminates any additional machining operations, in order to avoid additional costs.