Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

We are in the middle of a business innovation that sees a revolution in how companies create values in particular in their approach to innovation. A real revolution is given by combining technology and industrial assets.

In high pressure die casting industry both suppliers and customers are always looking for the best solutions in terms of part load, costs and times for development and manufacturing processes.

There can be many suppliers involved in the die casting process such as the raw material producer, the die caster, the toolmaker and others representatives of companies involving secondary operations. The right zinc die casting supplier is able to support its customer, anyway it is fundamental that the designer has knowledge of the material features and the process phases.

There are rules that need to be considered to design products or components in pressure die casting. The application of these advices will lead to a design that is logical, efficient and cost saving. In this article we will list some critical points to be taken into account when designing pressure die casting components.

Choosing the right supplier, in a wide range of zinc die casting manufacturers, is a tough issue. Having the right partner helps to reach planning and project goals and can be useful to develop a product or component in a co-design activity, while a bad partner could be a hard obstacle to catch the goals.

The history of Bruschi is linked to the concept of growing change. This concept, in general, assumes the capability to adapt to new conditions in accordance with the environment, interacting with different factors that are part of the system: in a continuous improvement imposed by the ability to win and face all the issues found on the way.

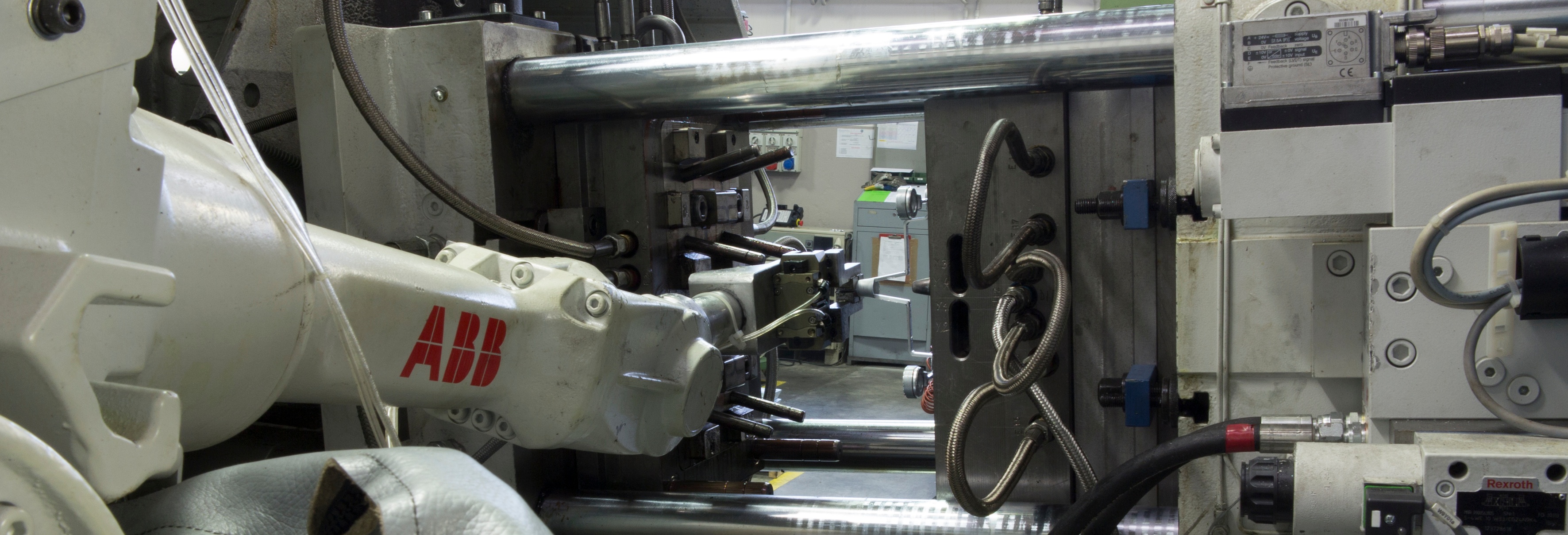

We are in the middle of a new industrial revolution: the fourth one. It’s called Industry 4.0. This term, used for the first time in Germany in 2010, is related to the digitalization of information. In this post we will see how Bruschi is approaching Industry 4.0 and how this new industrial revolution is affecting its business.

For a correct approach to product design for die casting it is important that every part involved has knowledge of the industrial process. These competences need to be part both of the client and the supplier's technology, to allow a co-design work that can improve the product or the component. In this article we are presenting two different perspectives of zinc die casting technology: product design and process design.

The term automation defines the introduction in a manufacturing company of technical tools and processes aimed at reducing or even eliminating human operations. The incorporation of automatic equipment produces several advantages, such as time saving, costs reduction and better quality outputs, thus achieving customers' satisfaction.

Excellent workplaces are organizations where the collaborators are enthusiastic about what they do and trust people around them. It is not just about skills, knowledge or expertise: but it is about the way to approach issues.