Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

In this post we are going to describe the benefits of die casting simulation, how to avoid non-compliant products creation, how to avoid material waste and how to save time avoiding empirical tests.

Working in Bruschi means passion and innovation. These two characteristics are the guidelines that every employee of the company has mixed to technical skills, expertise and capacity to face issues and challenges. In this post we are going to see how the invention of the vacuum valve has brought a relevant competitive advantage for Bruschi.

The concept of die casting mould design concerns the design of the mould but in general it defines the entire process of die casting. It’s a phase of the product industrialization that has clear characteristics to avoid many defects: for example cold laps.

In high pressure die casting, the filling process is crucial for the product esthetical quality and mechanical characteristics, for reducing scraps and optimizing set up parameters, and also for the maintenance and life cycle of the die.

A mold, in die casting terms, is a mechanic tool that allows to replay a product endless times, considered manufacturing limits, among the consolidation process of the same metal molten before. The mold is then the first actor in die casting field: so die casting mold design is a core activity to reach the customer needs.

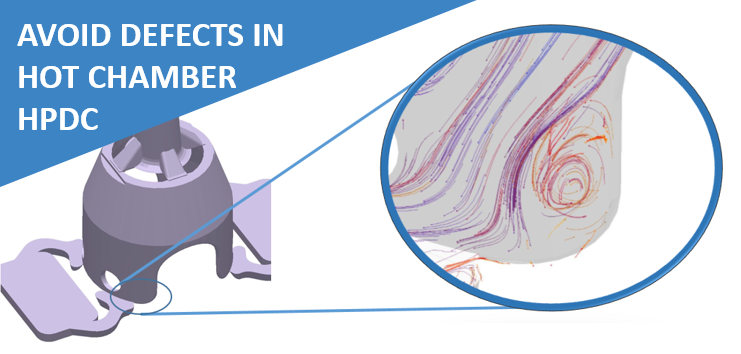

Hot chamber hpdc is a die casting process in which high pressure is used to force molten metal through a mould. The use of pressure let the metal flow through the die and leads to great qualities of castings especially when a perfect surface is needed. In hot chamber hpdc, the supply of molten metal is an integral part of the casting machine for the manufacturing operation.

Reducing scrap could be your next way to cut costs in die casting process. Saving allows you to invest in research and development, maybe right to find new ways to reduce scraps: in a sort of golden circle which allow your company to be more performing. In this case using the right methodology and the right tools the solution could be suitable for your company.

In this post we are going to describe both tangible and intangible benefits of simulation in die casting design. These advantages are cost reduction and value addition.

The activity of co-design is our way to support our costumer in the initial phase of project or improving existing products or components. Design products or components means face the complexity. Co-design is a crucial phase of the entire process of product design and Bruschi can help you in the all stages, such as simulation, prototyping, testing, accelerate time to market, process optimization.

In this blog post, we'll dive into the most common defects that can appear in high pressure zinc die casting and a possible way to avoid them: gas porosity, shrinkage porosity and leaks.