All the posts for die-casting-simulation

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

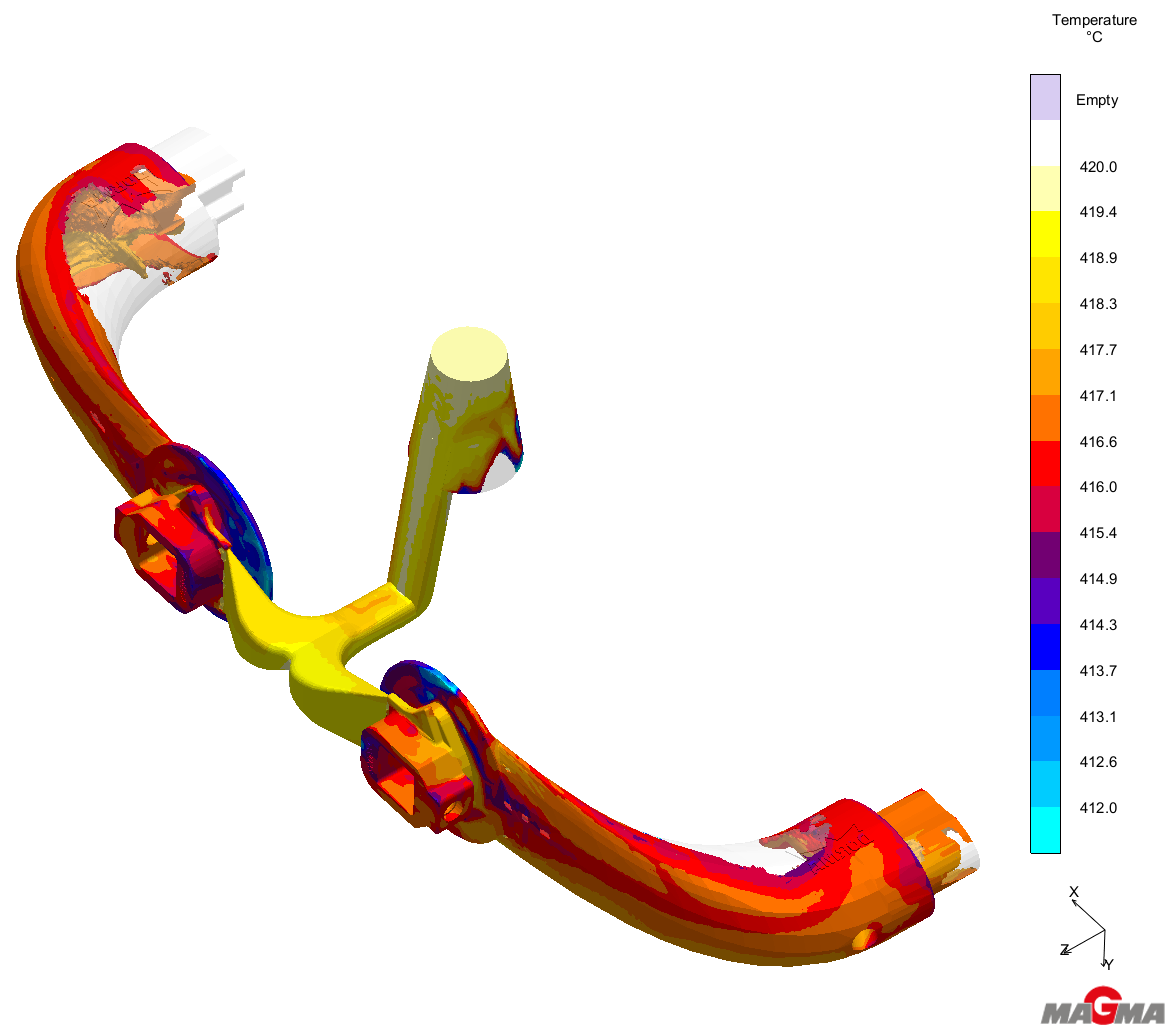

In this series of posts, we are going to explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of different case studies, in which simulation played a crucial role.

In this post we are going to talk about how the use of a HPDC simulation software can benefit the production.

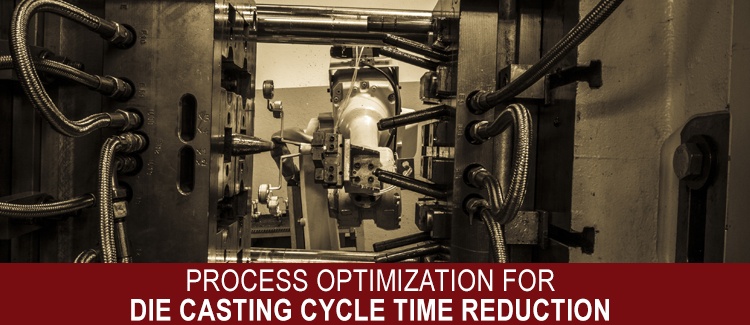

In the current industrial context, reducing production times will become ever more crucial to offer customers an optimal product in the shortest time possible, with consistent cost savings.

Just like atmospheric environment, which is different for corrosivity depending on where people are located in the world, the same is for metal corrosion in automotive parts: for example in Sweden the automotive environment is quite aggressive because of humid climate and of the use of de-icing salts causing metals corrosion.

Zinc die casting finishes are processes applied in order to modify surfaces of manufactured items, products or components with the purpose of reaching client requirements and improve functional and aesthetical quality of a product.

In die casting, zinc die casting finishing process might improve the product appearance and performance. Zinc die casting parts can be submitted to different kinds of post treatments for many reasons, such as improving a product appearance, conferring resistance to chemicals, corrosion and wear, improving or modifying electrical conductivity and removing burrs and other flaws.

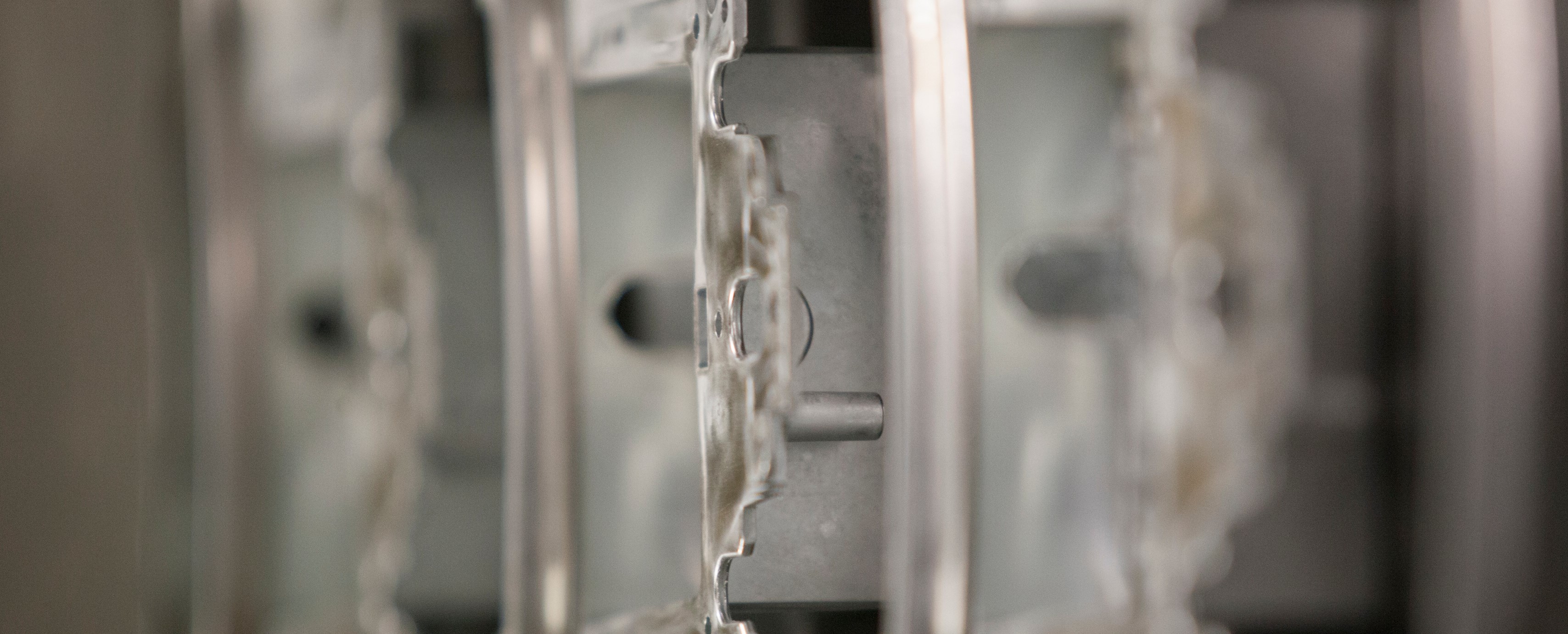

Shrinkage porosity defects are cavities inside components which can cause material weakening and, if positioned on surface, can worsen aesthetic quality and corrosion resistance.

Zinc die casting process can have important advantages compared to other manufacturing process: for example can lead to major cost savings during production cycle, allows to create complex product shapes and is possible to eliminate unnecessary assembly operations combining multiple components into a single one.

Nowadays using technology software such as die casting simulation allows optimizing the whole production cycle. Today’s ever-changing international marketplace is highly demanding and challenging: using the newest tools from supplier side mean giving clients innovative solutions to reach their expectations. The following article will explain how to obtain consistent savings with die casting simulation.

Choosing the perfect zinc die caster is an important issue: this choice could determine the good or bad outcome of a product. In order to reach clients’ expectations is important to consider every production aspect: to organize it in the best way possible it is important to analyze the entire production process.