All the posts for die-casting-simulation

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

A mold, in die casting terms, is a mechanic tool that allows to replay a product endless times, considered manufacturing limits, among the consolidation process of the same metal molten before. The mold is then the first actor in die casting field: so die casting mold design is a core activity to reach the customer needs.

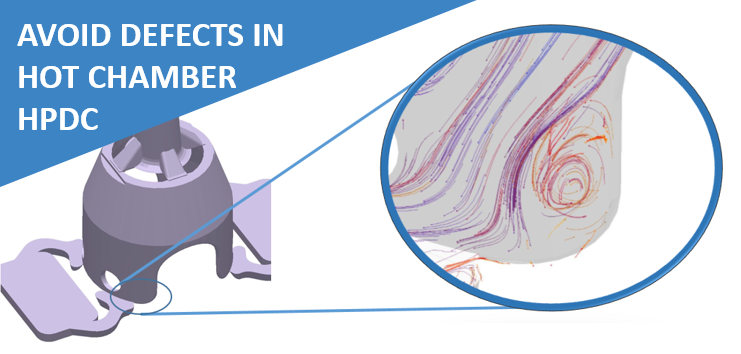

Hot chamber hpdc is a die casting process in which high pressure is used to force molten metal through a mould. The use of pressure let the metal flow through the die and leads to great qualities of castings especially when a perfect surface is needed. In hot chamber hpdc, the supply of molten metal is an integral part of the casting machine for the manufacturing operation.

Reducing scrap could be your next way to cut costs in die casting process. Saving allows you to invest in research and development, maybe right to find new ways to reduce scraps: in a sort of golden circle which allow your company to be more performing. In this case using the right methodology and the right tools the solution could be suitable for your company.

In this post we are going to describe both tangible and intangible benefits of simulation in die casting design. These advantages are cost reduction and value addition.

In this blog post, we'll dive into the most common defects that can appear in high pressure zinc die casting and a possible way to avoid them: gas porosity, shrinkage porosity and leaks.