All the posts for co-design

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

In this post we are going to discuss how it is possible to reduce components weight while maintaining their functionality through the use of co-design.

In this article we are going to analyze product design for die casting through the study of a DFM (Design for Manufacturability) and suggesting a way to optimize and speed up the process: co-design.

Commodity prices volatility is driven by worldwide demand and other variables: it is basically about rise and fall, but there are different options in order to optimize the cost. In particular, this article focuses on metal and tries to find solutions on how a die caster can help a manufacturer to avoid the increase of production costs.

Just like atmospheric environment, which is different for corrosivity depending on where people are located in the world, the same is for metal corrosion in automotive parts: for example in Sweden the automotive environment is quite aggressive because of humid climate and of the use of de-icing salts causing metals corrosion.

Black zinc is a zinc plating treatment which gives aesthetic and functional characteristics to products' surface. In this article we are going to deeply and technically analyze this treatment but, first of all, it could be useful to have an introduction on zinc plating main characteristics and which different types are most commonly used.

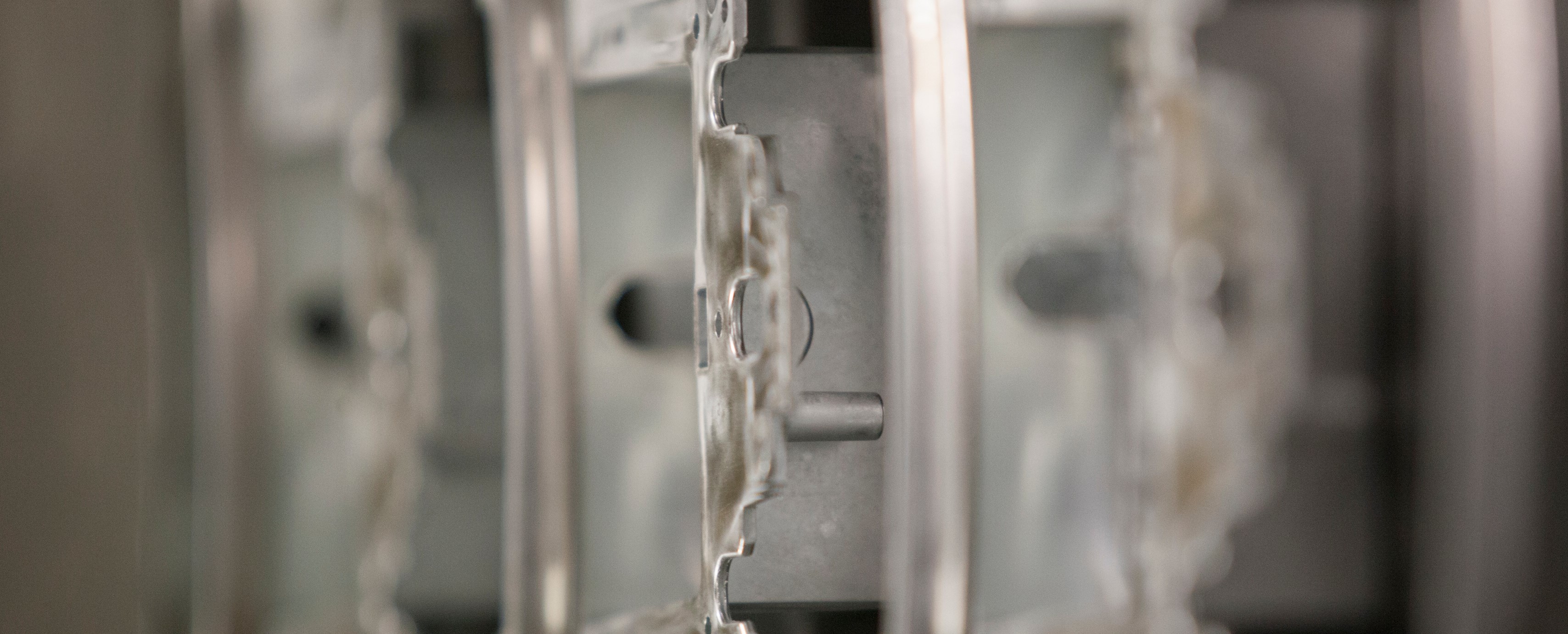

Die casting surface treatments are operations that lead to obtain a finished product starting from the casting aiming at increasing aesthetical and functional characteristics of a product or component. Can be either production cycle last phase or a step, where component surface is prepared for other following treatments.

There are different types of suppliers that are involved in die casting process: the raw material producer, the toolmaker, the die caster, and experts of secondary operations. The most important supplier involved in the product design phase is the zinc alloys die caster. In fact the supplier should foresee in advance the casted product performance, its aesthetical requirements and its total costs.

Zamak die casters cannot be choose without a mindful analysis. Choosing the right supplier can be a tough issue: it is fundamental that zamak die casters are able to understand if die casting is the right choice for the production of the component requested, or instead advice the client to use another technology.

Among die casting services a supplier may offer to its customers, co-design is fundamental to realize a product with specific technical requirements. Co-design is the collaboration between the client and the die casting supplier, and it is fundamental to realize a product that has technical characteristics requested for its functionality and its aim and is at the same time in compliance to the process of die casting.

Product design is an important part in die casting engineering which can be optimized adding a co-design process. Co-design activity is composed of three different phases: prrocess design, cost analysis and product design.